Film for hydraulic transfer

A water pressure transfer printing and substrate layer technology, which is applied in printing, printing process, printing device, etc., can solve the problems of difficult water pressure transfer printing, reduce the printing image precision, affect the surface of the printing layer, etc., and achieve accurate water pressure transfer printed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

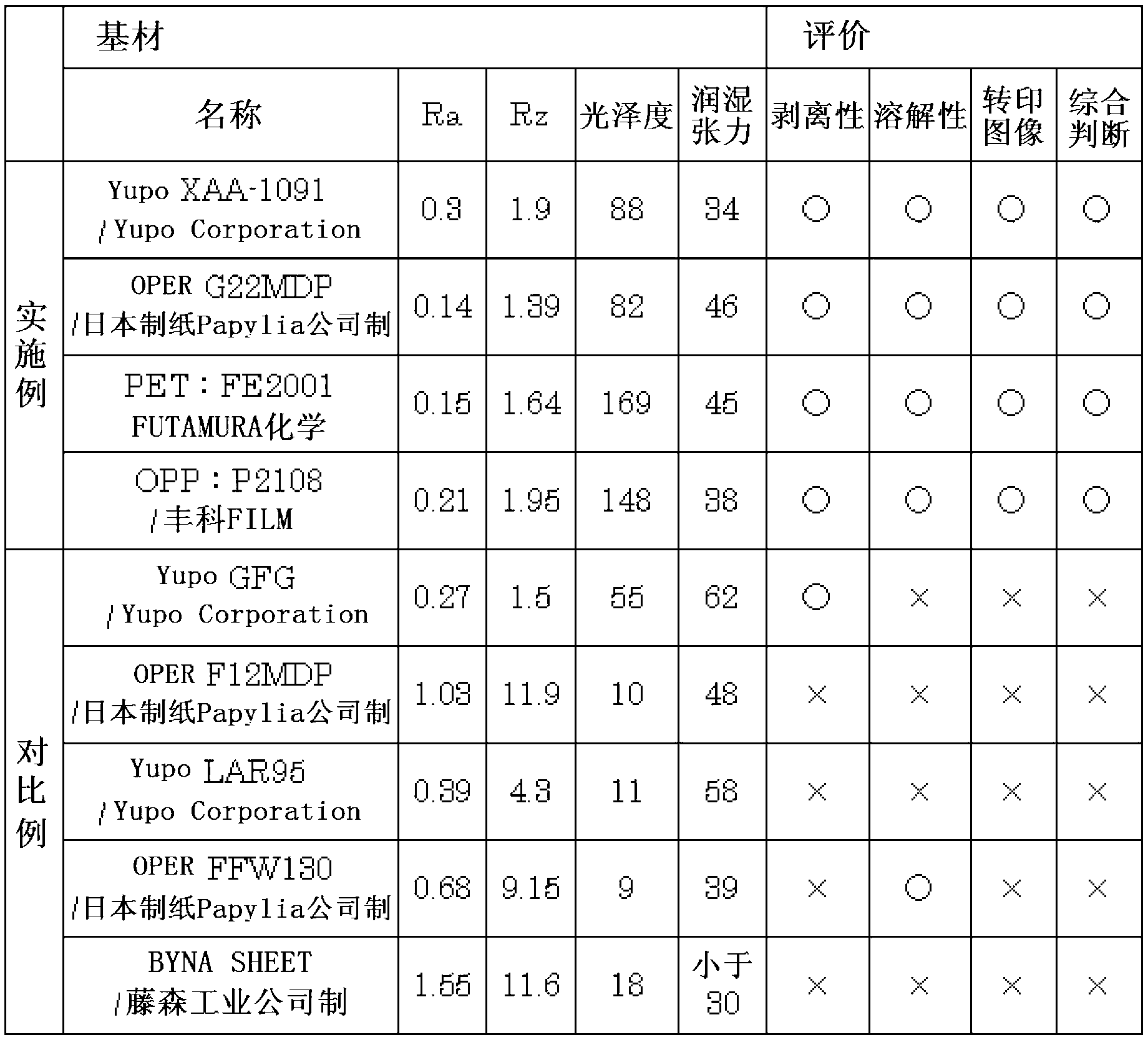

[0096] Examples are shown below to describe the present invention more specifically, but the present invention is not limited thereto. Among them, examples are shown regarding the composition of a two-layer film for hydraulic transfer in which polyvinyl alcohol having a degree of polymerization of 2000 and a degree of saponification of 88 mol % as a print receiving layer is laminated on a substrate layer with a thickness of 30 μm.

[0097] (Evaluation of samples)

[0098] Surface Roughness Evaluation

[0099] In an environment of 23° C. and 50% RH, Ra and Rz were measured with a roughness meter (manufactured by Accretech: Handysurf E-35A). Gloss was measured with a gloss meter (manufactured by Nippon Denshoku Kogyo Co., Ltd.: Gloss Meter VG7000).

[0100] Peelability evaluation

[0101] The print-receiving layer made of PVA laminated on the A4 size base material was pulled and peeled by hand, and the peeling state was evaluated.

[0102] The detachability was classified in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| wetting tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com