Processing method for biological material to produce water -retaining polymer complex

A biomaterial, water retention technology, used in fertilizer mixtures, animal carcass fertilizers, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] 1. Production of meat-based water-retaining polymer composites

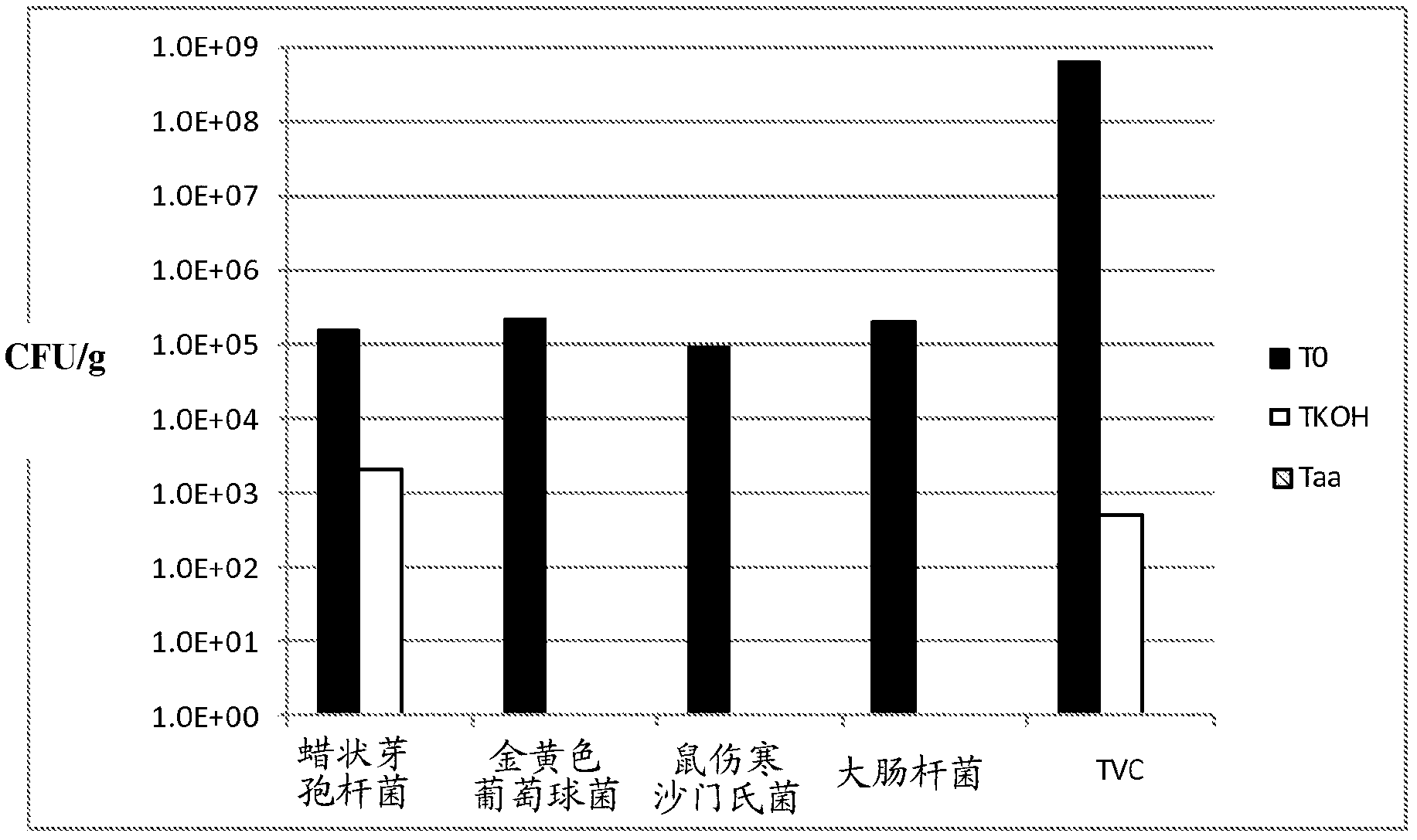

[0042] Prepare 100 ml of a 30% alkaline solution (5 g KOH and 25 g NaOH). During this (exothermic) process the water temperature rose from 23°C to 60°C. 100 g of organic waste (minced meat) was dissolved in the solution, which lowered the temperature of the solution to 55°C. The high temperature and highly alkaline conditions of the solution can result in a 6 log reduction in total viable count (see below). Once the temperature of the solution had dropped to 45°C, 30ml of acrylic acid was added. This raised the temperature to 62°C. After 5 minutes, 0.5 g of ammonium persulfate (APS) was added to the solution as a polymerization agent and polymerization occurred within 15 minutes. APS was added to the solution to raise the temperature of the solution to 70°C. The resulting complex had a pH of 7.7.

[0043] 2. Water holding capacity (WHC) of meat-based water-retaining polymer composites

[0044] To me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com