Lithium battery test box with automatic fire extinguishing device

An automatic fire-extinguishing and test chamber technology, applied in fire rescue and other directions, can solve the problems of no rapid cooling and fire-extinguishing functions, fire, explosion, etc., to achieve the effect of high-temperature detection and automatic fire-extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

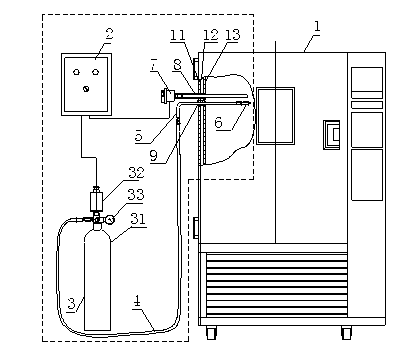

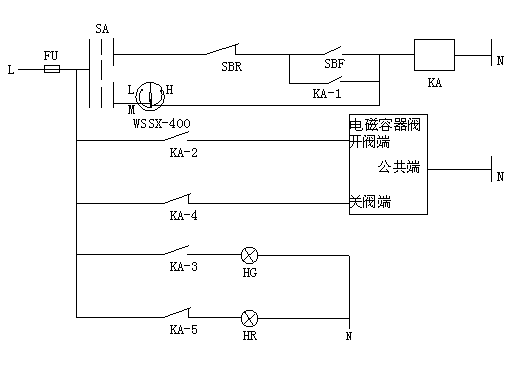

[0025] like Figure 1 to Figure 2 As shown, the lithium battery test box with automatic fire extinguishing device includes a test box body 1 and a set of automatic fire extinguishing device. The automatic fire extinguishing device consists of fire extinguishing control box 2, heptafluoropropane fire extinguishing agent bottle group 3, rubber hose 4, steel pipe 5, nozzle 6. Electric contact thermometer 7, sensor probe conduit 8, steel pipe casing 9;

[0026] The fire extinguishing control box 2 and the heptafluoropropane fire extinguishing agent bottle group 3 are placed outside the test box 1; the heptafluoropropane fire extinguishing agent bottle group 3 includes a fire extinguishing agent cylinder 31, an electromagnetic container valve 32 and a pressure gauge 33;

[0027] The box wall of the test box 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com