Material of non-woven fabric surface heavy nitrogen coupling gelatin adsorbing material and preparation method thereof

An adsorption material, non-woven technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of slow washing speed, high price, influence of adsorption and filtration properties, etc. Water flow pressure loss, high filtration stability, the effect of increasing affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

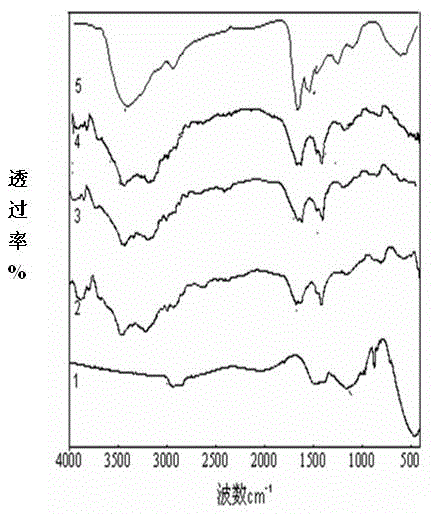

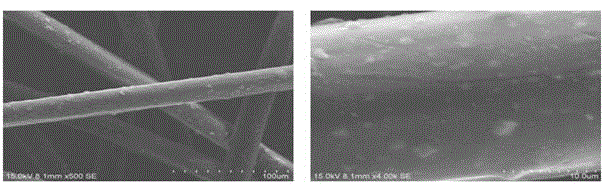

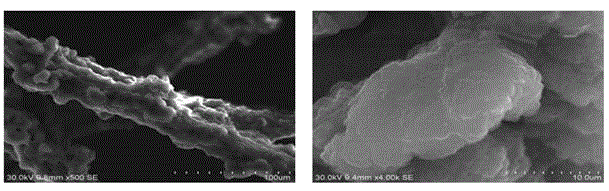

Image

Examples

Embodiment 1

[0042] Example 1: The method for preparing the adsorption material of diazonium coupled gelatin on the surface of the non-woven fabric is as follows:

[0043] (1) Preparation of acrylic grafted product of PP non-woven fabric

[0044] Refer to the method in the Chinese patent application (application number 201010559722.2) "A high carboxyl content ion exchange non-woven fabric and its preparation method", the specific operations are as follows:

[0045] A. Cut a batch of round PP non-woven fabrics with a diameter of 8cm (commercially available, specification: 8.5g / m 2 , Thickness of 64.5μm, water absorption rate of 58.1%), soak in acetone for 12h to remove impurities such as surface oil and additives, take it out and dry for use;

[0046] B. Mix acetone with 50% (volume percentage) and distilled water to form a mixed solvent, add acrylic acid, benzophenone and azobisisobutyronitrile to form a monomer solution for use. The concentration of each component is 50% acrylic acid (volume perc...

Embodiment 2

[0060] Example 2: The method for preparing the adsorption material of diazo coupled gelatin on the surface of the non-woven fabric is as follows:

[0061] (1) Preparation of acrylic acid grafted product on PP non-woven fabric

[0062] Refer to the method in the Chinese patent application (application number 201010559722.2) "A high carboxyl content ion exchange non-woven fabric and its preparation method". The specific operation is the same as the step (1) of Example 1. This example uses polypropylene (PP) Non-woven fabric, carboxyl group-containing unsaturated monomer is acrylic acid, the carboxyl group content Sg of the acrylic acid grafted product of the obtained PP non-woven fabric is 9.4mmol / g, and its water absorption rate is 908.2%

[0063] (2) Preparation of PP non-woven fabric p-phenylenediamine amination product

[0064] The PP non-woven acrylic grafted product is put into a mixture of p-phenylenediamine, N, N dimethylformamide DMF and catalyst AlCl 3 .6H 2 In the solution o...

Embodiment 3

[0074] Example 3: The method for preparing the adsorption material of diazo coupled gelatin on the surface of the non-woven fabric is as follows:

[0075] (1) Preparation of acrylic acid grafted product on PP non-woven fabric

[0076] Refer to the Chinese patent application (application number 201010559722.2) "a high carboxyl content ion exchange non-woven fabric and its

[0077] The method in "Preparation Method" is carried out, and the specific operation is the same as the step (1) of Example 1. In this example, polypropylene (PP) non-woven fabric is used, and the carboxyl-containing unsaturated monomer is acrylic acid. The obtained PP non-woven fabric acrylic graft product The carboxyl group content Sg is 10.4mmol / g, and its water absorption rate is 1126.9%;

[0078] (2) Preparation of PP non-woven fabric p-phenylenediamine amination product

[0079] The PP non-woven acrylic grafted product is put into a mixture of p-phenylenediamine, N, N dimethylformamide DMF and catalyst AlCl 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com