Electromagnetic power take-off system and power take-off method of micro-card dump garbage truck

A garbage truck and electromagnetic technology, applied in garbage receptacle, transportation and packaging, etc., can solve the problems of small size of power unit, inflexible installation position of micro card chassis, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

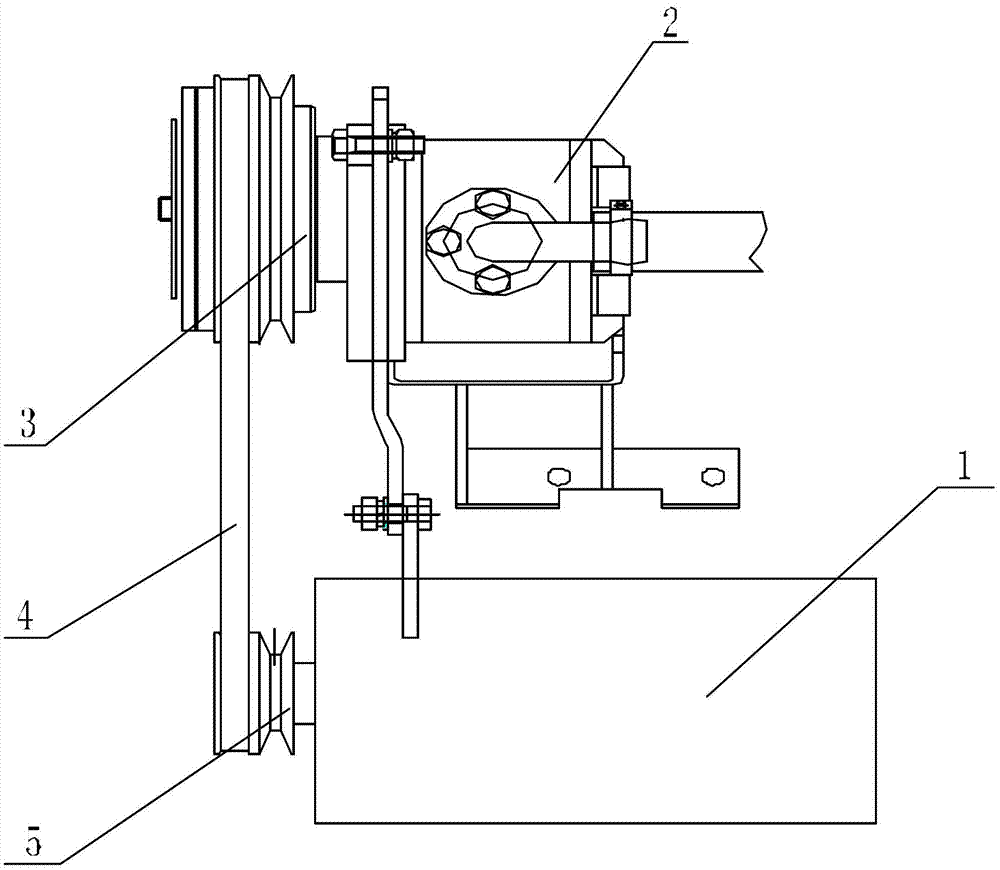

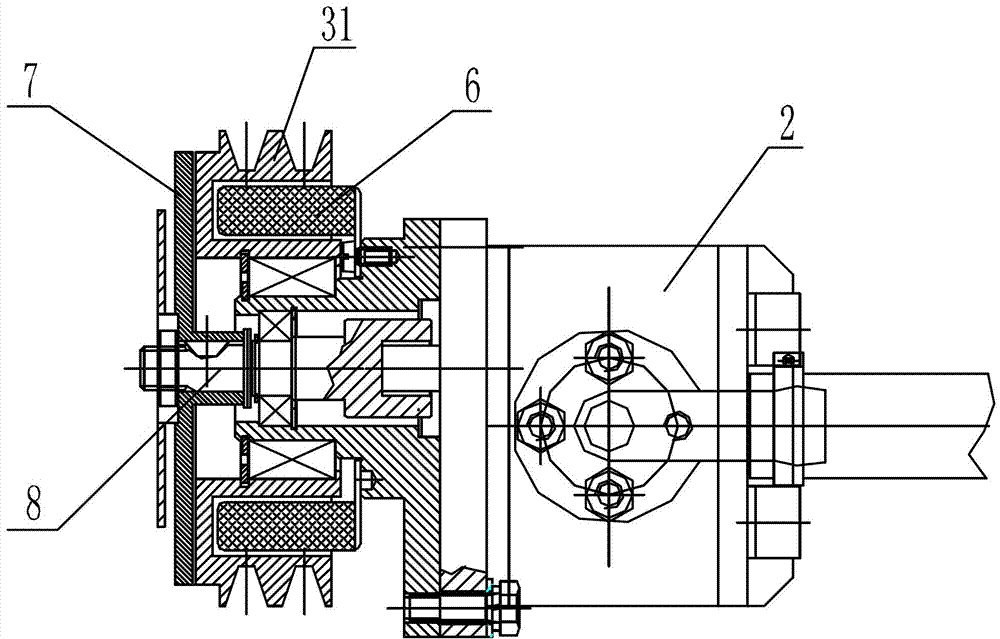

[0022] Such as Figure 1 ~ Figure 2 As shown, an electromagnetic power take-off system of a micro-card dump truck includes an engine 1 and an electromagnetic clutch 3, the engine 1 is provided with an engine power output wheel 5, the electromagnetic clutch 3 is provided with an electromagnetic clutch power input wheel 31, and the electromagnetic clutch The power input wheel 31 is dynamically connected with the engine power output wheel 5 . Engine 1 outputs power by engine power output wheel 5, and this power output is on the electromagnetic clutch power input wheel 31 of electromagnetic clutch 3, drives the electromagnetic clutch power input wheel 31 of electromagnetic clutch 3 to rotate, makes and electromagnetic clutch power input wheel 31 Other equipment or devices connected to the power are in normal operation.

[0023] Such as figure 2 As shown, the inner center shaft of the electromagnetic clutch 3 is provided with a bearing sleeve, and an intermediate shaft 8 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com