Device for synchronously measuring axial displacement and radial displacement of a rigid coupler

A rigid coupling and synchronous measurement technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve problems such as increasing the difficulty of installation and construction, wasting manpower and material resources, and restricting smooth progress, so as to achieve effective use of space, The effect of saving cost and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

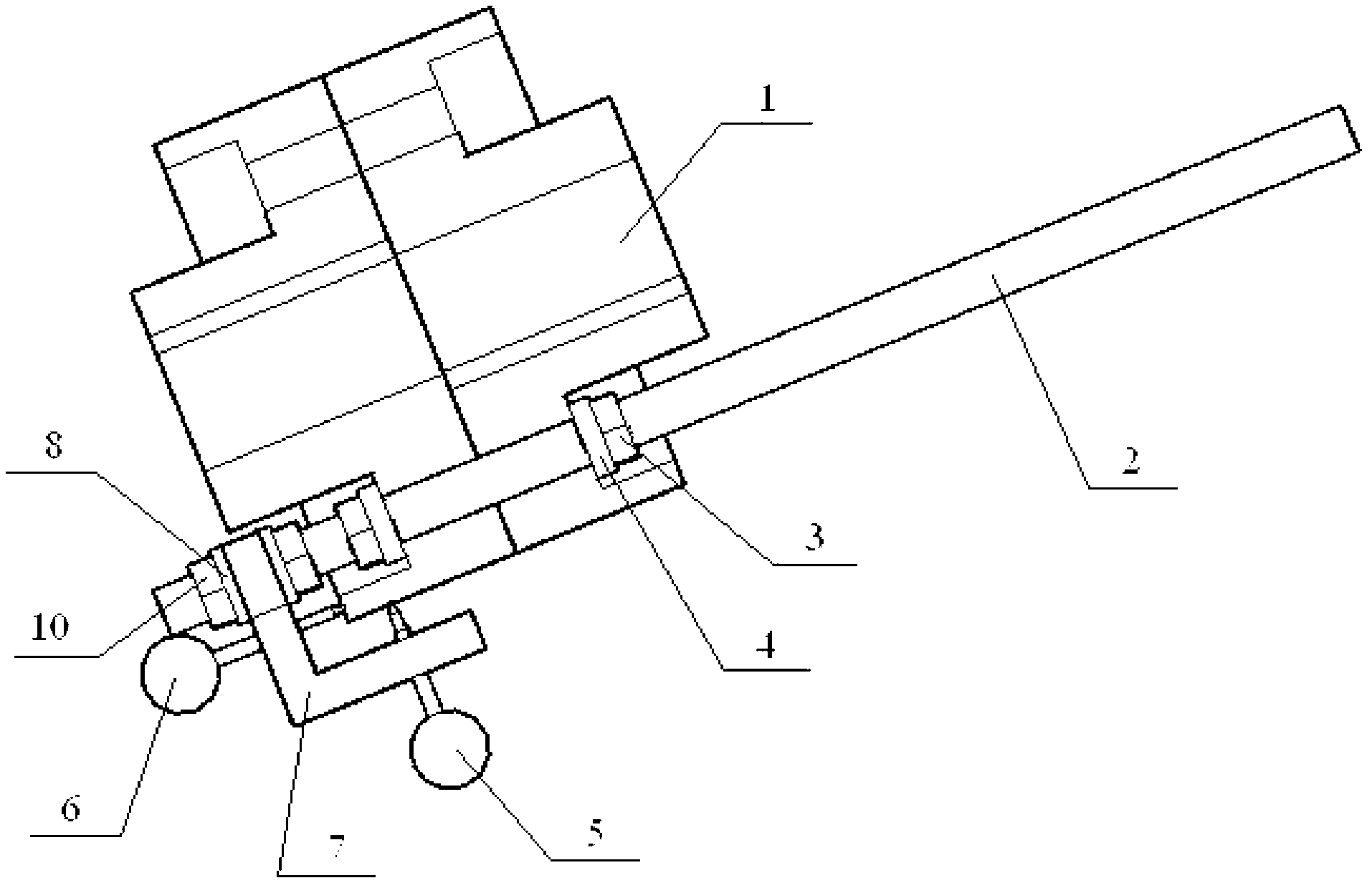

[0023] A device for simultaneously measuring the axial and radial displacement of a rigid coupling, such as figure 1 As shown, it includes a support rod 2, an axial measuring device 6 arranged on a bracket 7 for measuring axial deviation, and a radial measuring device 5 for measuring radial deviation.

[0024] The support rod 2 is threaded through the corresponding bolt holes of the two half-couplings during measurement, and the outer circumference of the support rod 2 is threaded. A pair of nuts I3 are arranged on the support rod 2, and the nuts I3 are located on both sides of the rigid coupling 1, and are fixedly connected to the support rod 2 and the rigid coupling 1. In order to prevent the side end surface of the rigid coupling 1 from being damaged when the nut I3 is tightened, a flat washer I4 is arranged between the side end surface of the rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com