Ultrasonic flow meter

A flowmeter and ultrasonic technology, applied in the field of ultrasonic flowmeters, can solve the problems of ultrasonic signal attenuation, affecting water field changes, inaccurate measurement, etc., and achieve the effects of improving linearity, improving measurement accuracy, and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

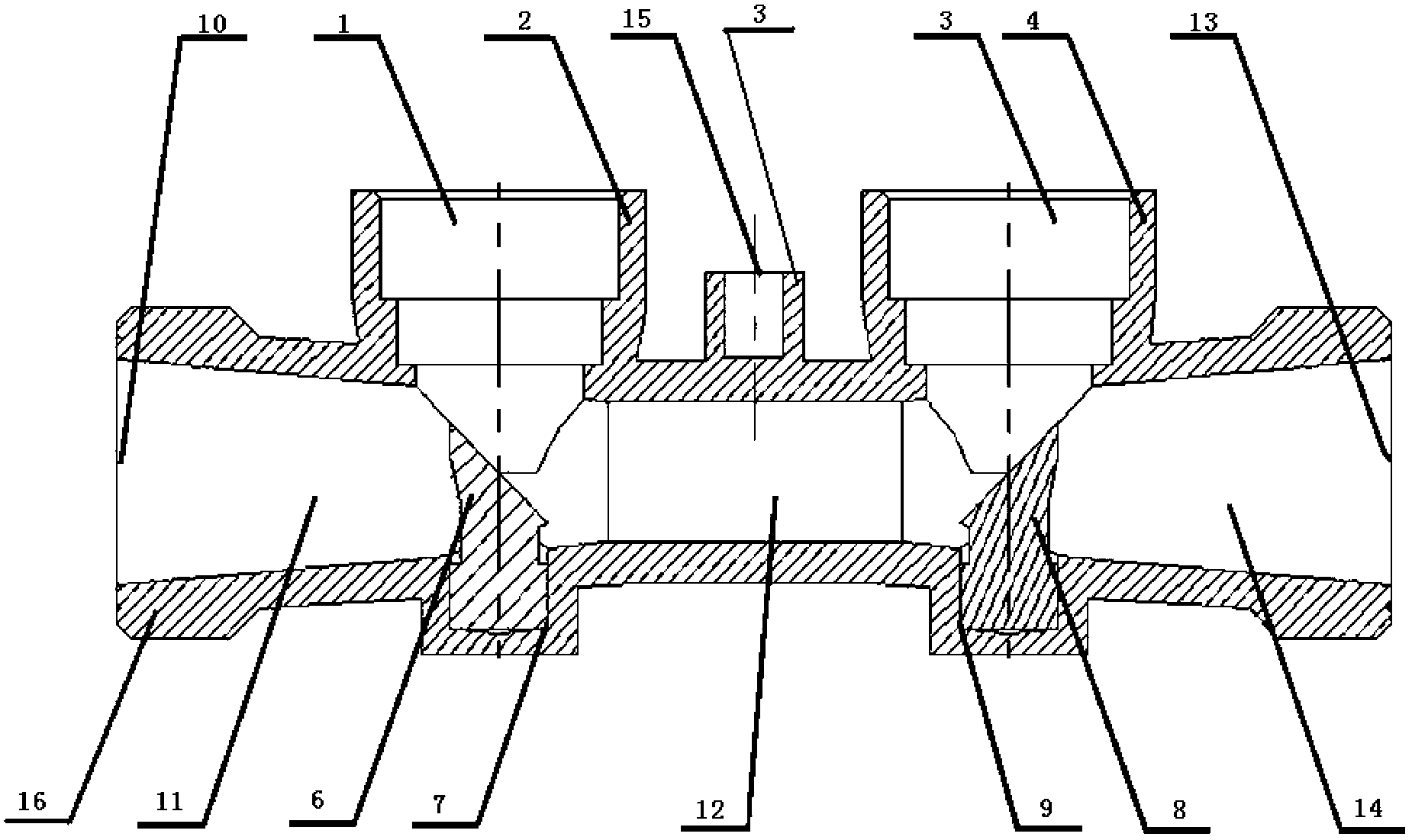

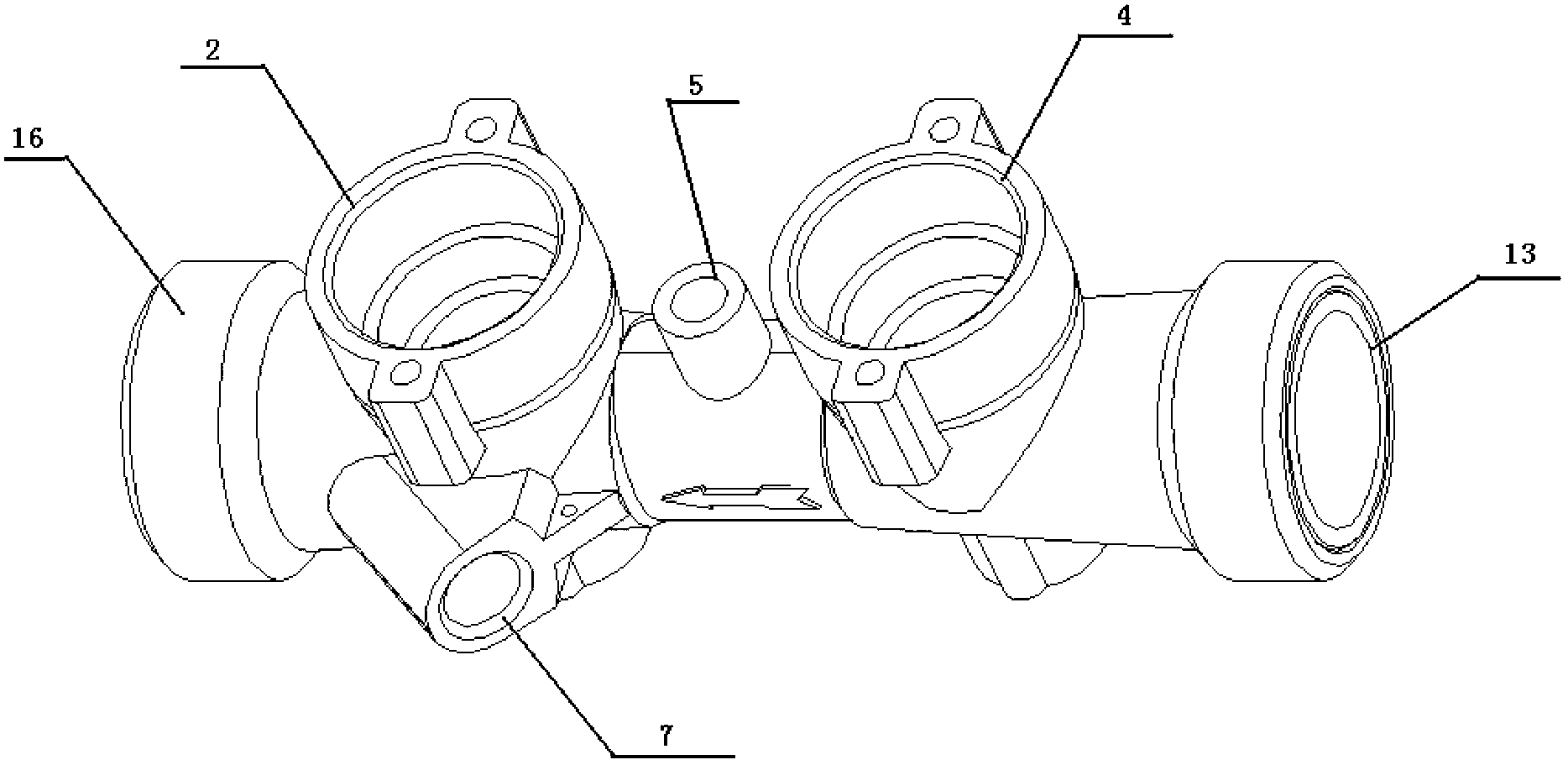

[0038] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

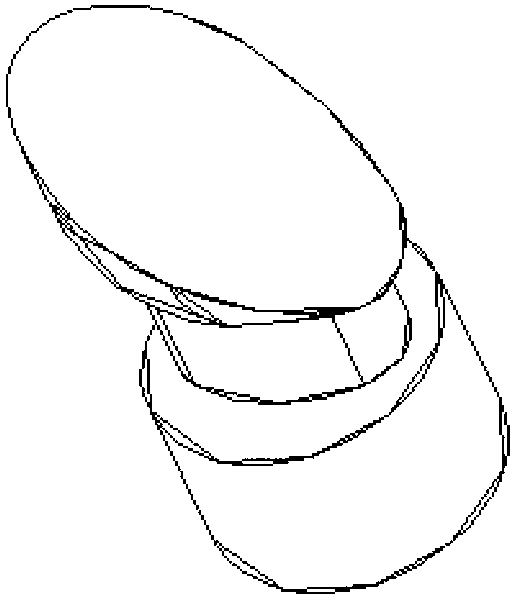

[0039] An ultrasonic flowmeter, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a flow meter cavity 16, a water inlet spindle-shaped through hole 11, a flow measuring hole 12, a water outlet spindle-shaped through hole 14, a water inlet port transducer 1, a water outlet port transducer 3, and a water inlet end Ship reflection column 6 (such as image 3 , Figure 4 Shown) and ship-shaped reflecting column 8 at the outlet end (as image 3 , Figure 4 (Shown), the water inlet spindle-shaped through hole 11, the flow measuring hole 12, and the water outlet spindle-shaped through hole 14 are all located inside the flow meter cavity 16, and the water inlet spindle-shaped through hole 11, The flow measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com