Compressed air supply installation, pneumatic system and method for operating a pneumatic installation

A technology for compressed air and pneumatic equipment, applied in the field of vehicle air spring equipment and pneumatic systems, and can solve problems such as feasibility limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

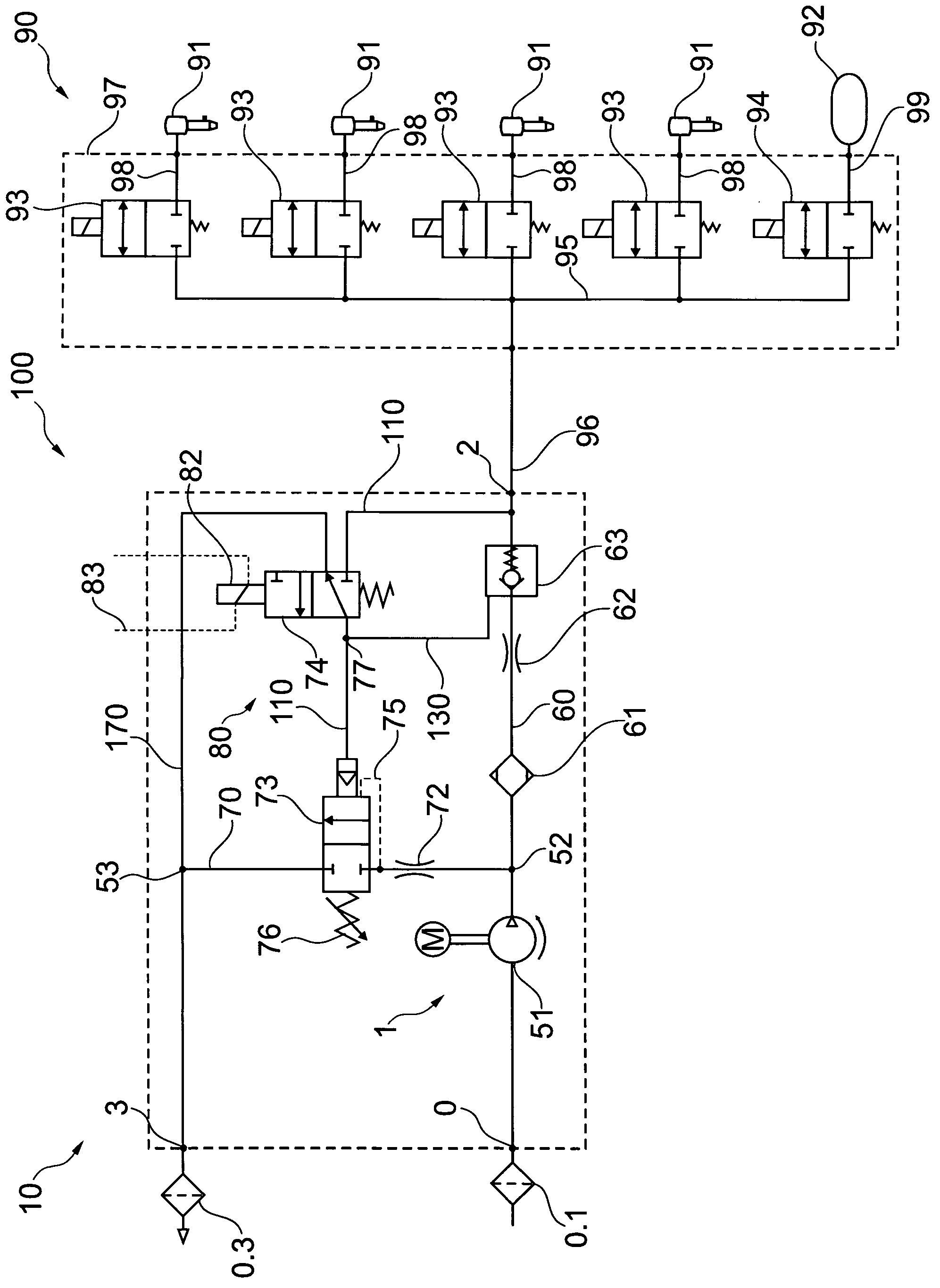

[0108] figure 1 A pneumatic system 100 is shown with a compressed air supply device 10 and a pneumatic device 90 in the form of an air spring device. In this case, the air spring arrangement has four so-called bellows 91 which are each associated with a wheel of the vehicle (not shown in detail) and form the air springs of the vehicle. Furthermore, the air spring device has a storage device 92 for storing rapidly available compressed air for the bellows 91 . Arranged upstream of the bellows 91 in each spring branch line 98 is a solenoid valve 93 , which in each case serves as a level regulating valve for opening or closing the air spring formed by the bellows 91 . The solenoid valve 93 in the spring branch line 98 is designed as a 2 / 2-way valve. A solenoid valve 94 in the form of a further 2 / 2-way valve is arranged upstream of the accumulator 92 as an accumulator valve in the accumulator branch line 99 . The solenoid valves 93 , 94 are connected by means of spring branch l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com