Ultrasonic flowmeter

An ultrasonic and flowmeter technology, applied in the direction of volume measurement, flow measurement/mass flow, liquid/fluid solid measurement, etc., can solve problems such as complex structure, increased time resolution, and adverse effects of flow coefficient flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

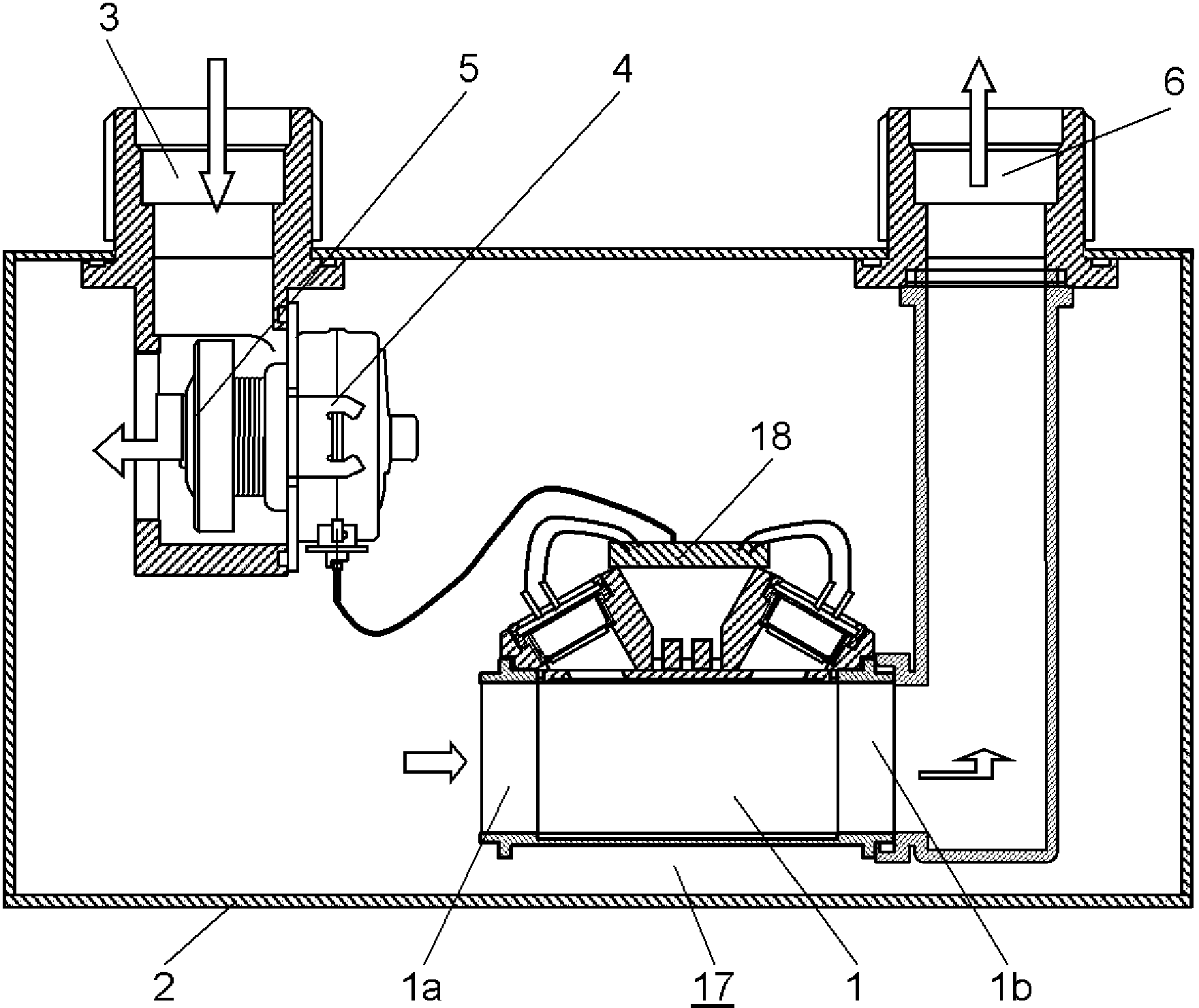

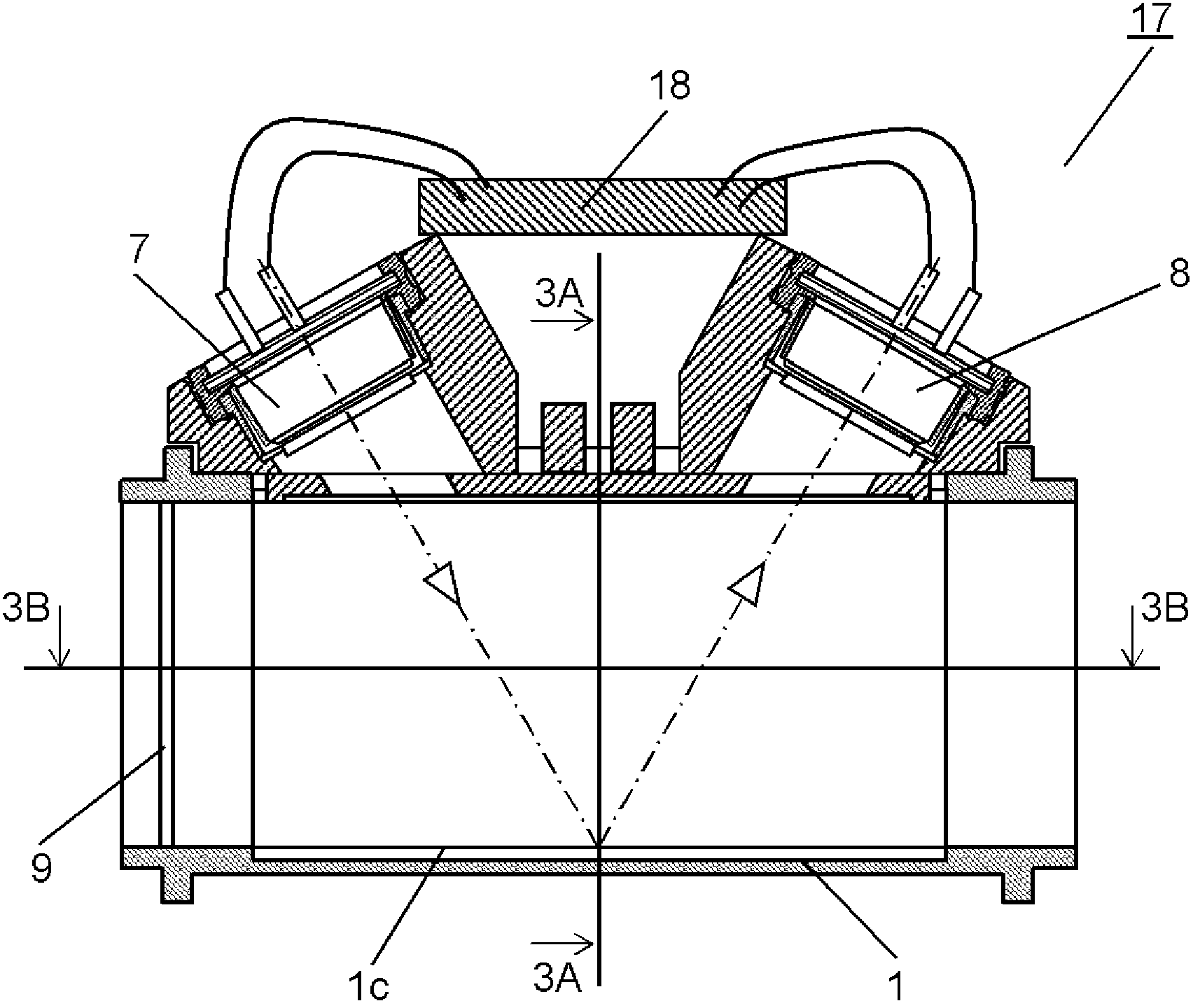

[0026] Such as figure 1 As shown, a shutoff valve 5 is provided in the middle of the fluid supply path 3, and the shutoff valve 5 is opened and closed by a valve body that cooperates with a drive unit 4 using an electromagnetic device such as a stepping motor. The hollow arrow indicates the flow direction of the fluid to be measured, and the fluid to be measured flows out from the fluid supply channel 3 to the inside of the measuring device housing 2 when the valve is in an open state. The measurement channel 1 is a rectangle with a rectangular cross section. The fluid to be measured that fills the inside of the measuring device case 2 flows into the measuring flow path 1 from the upstream side 1a that is the inlet side of the measuring flow path 1, and flows into the measuring device case 2 via the fluid outflow path 6 connected to the downstream side 1b. external outflow.

[0027] In addition, the shutoff valve 5 is closed when an abnormality occurs in the fluid flow, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com