Organosiloxane polymer, preparation method of the organosiloxane polymer, color photoresist for color filter, color filter and preparation method of the color filter

A technology of organosiloxane and polymer, which is applied in the field of color filters, and can solve the problems of decreased flatness of color filters and improper use of coupling agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

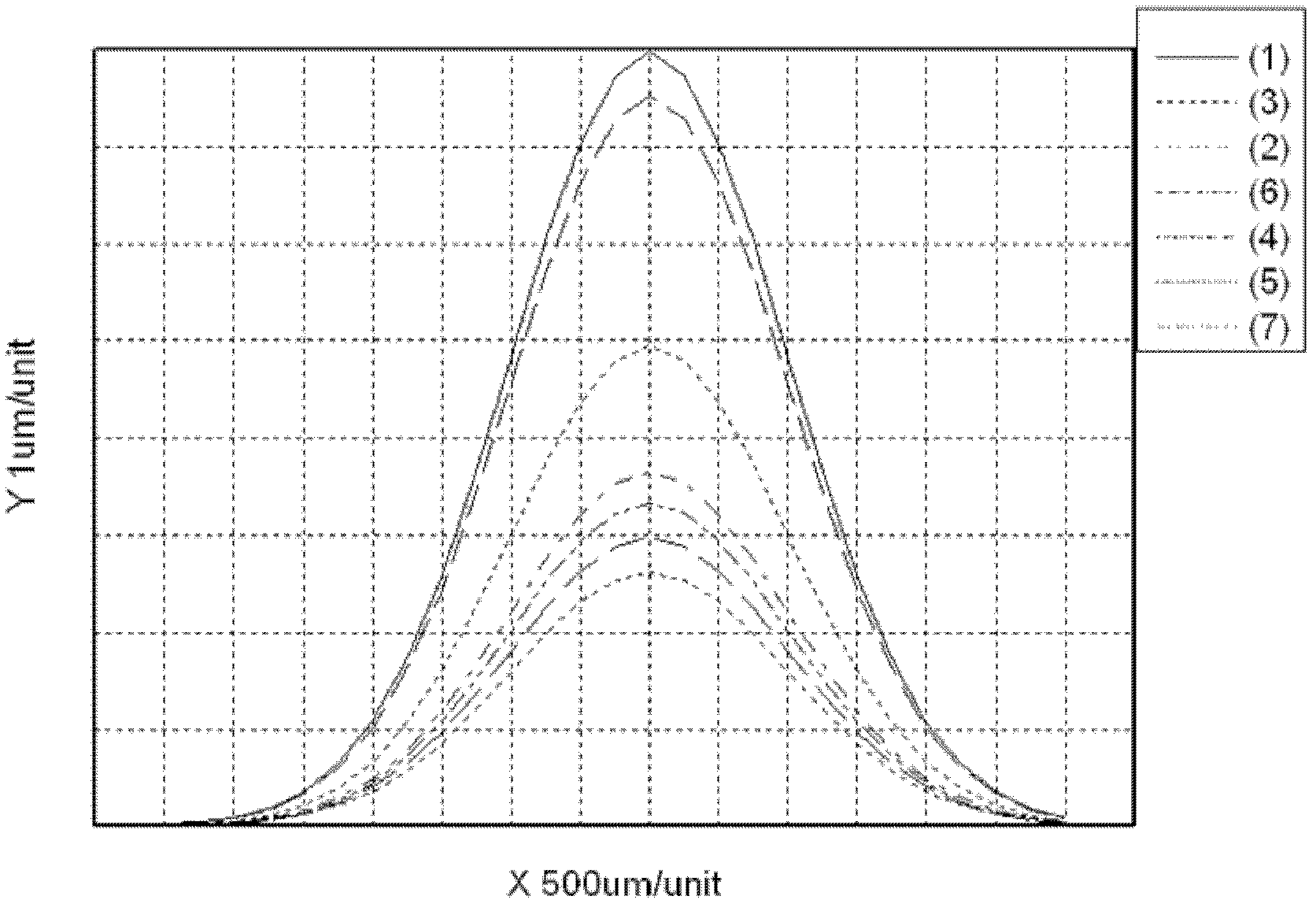

Image

Examples

Embodiment 1

[0069] Take 1.62 parts of BYK-302 (polyether-modified polydimethylsiloxane), 6.49 parts of the compound shown in chemical formula 3-2; 20 parts of cyclohexanone; add it into a four-necked flask, and put Enter magneton, device condensation tube, thermometer; Connect nitrogen, 3 parts of sulfuric acid (60% concentration) are installed on the four-necked flask after packing into constant pressure dropping funnel, 80rpm stirring speed is connected in 70 degree water bath and reacted 2 hours, reduce Distill under pressure for 0.5 hours to remove by-products, lower the temperature to 50°C, and continue the reaction for 8 hours to end the reaction. Add 60 parts of n-hexane to precipitate the product, filter with Buchner funnel, and dry to obtain intermediate 4-1.

Embodiment 2

[0071] Get 3.24 parts of Ciba-EFKA-3883 (double-bond-terminated polyether modified silicone), and 1.26 parts of the compound represented by the above chemical formula 3-1 and 3.61 parts of the compound represented by 5-6; 20 parts of cyclohexanone; add four In the four-necked flask, put magnets in the four-necked flask, install a condenser, a thermometer, and communicate with nitrogen; 3 parts of aqueous nitric acid (1000ppm) are installed on the four-necked flask after being loaded into a constant pressure dropping funnel, and the stirring speed is connected to 240rpm. Put it in a water bath of 60 degrees to react for 2 hours, distill under reduced pressure for 0.5 hours to remove by-products, cool down to 50 degrees, continue to react for 8 hours, end the reaction, add 60 parts of n-hexane to precipitate the product, filter with Buchner funnel, and dry to obtain intermediate Body 4-2.

Embodiment 3

[0073] Take 1.62 parts each of Ciba-EFKA-3883 (double-bond-terminated polyether-modified silicone) and Ciba-EFKA-3034 (fluorocarbon-containing polyether-modified silicone), and 4.87 parts of the compound represented by the above chemical formula 3-2 20 parts of pimelinketone; add in the four-necked flask, and put into magneton in the four-necked flask, device condenser, thermometer, connect nitrogen, install after 3 parts of sulfuric acid (60% concentration) pack into constant pressure dropping funnel On the four-neck flask, 120rpm stirring speed was connected to a 60-degree water bath for 2 hours, and the by-products were removed by vacuum distillation for 0.5 hours. The temperature was lowered to 50 degrees, and the reaction was continued for 8 hours. The reaction was terminated, and 60 parts of n-hexane was added to precipitate the product. , filtered through a Buchner funnel, and dried to obtain intermediate 4-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com