Red mud composite material and repairing method thereof for soil

A technology of composite materials and red mud, which is applied in the field of soil remediation, can solve the problems of unrecorded preparation method of composite red mud material ratio, drastic changes in soil properties, and difficult restoration, so as to achieve good repair effect and realize comprehensive utilization of resources , the effect of a reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Red mud composite material ingredients

[0035] 78g of red mud; cement: 5g of plaster of paris, 7g of Portland cement; inorganic additives: 2g of acid-activated biochar, 6g of dipotassium hydrogen phosphate; 2g of compost, water and pore former op; the water quality is the total dry material (Red mud, cement, inorganic additives, compost) 55% of the mass, and the pore former op mass is 0.3% of the water mass.

[0036] 2. Preparation of red mud composite material

[0037] First mix the red mud with the cement, then add the aqueous solution containing the pore former op, mix and stir evenly, let it stand for 2 minutes, then add the inorganic additives and compost, mix and stir it, and let it stand for 8 minutes. Extrusion granulation in swing granulator, rotating speed 60 rpm, passing through 60 mesh sieve to obtain granularity Particles <0.250mm.

Embodiment 2

[0039] 1. Red mud composite material ingredients

[0040] 70g red mud; cement: 5g plaster of paris, 5g portland cement; inorganic additives: acid activated biochar 3g, dipotassium hydrogen phosphate 13g; compost 4g, water and pore former op, where the water quality is the total dry material (Red mud, cement, inorganic additives, compost) 52% of the mass, and the pore former op mass is 0.1% of the water mass.

[0041] 2. Preparation of red mud composite material

[0042] First mix the red mud and the cementitious material, then add the aqueous solution containing the pore former op, mix and stir evenly, let it stand for 1 minute, then add the inorganic additives and compost, mix and stir evenly, then let it stand for 5 minutes, put the mixture into Squeeze granulation in a swing granulator, rotate at 55 rpm, and pass through a 60 mesh sieve to obtain the granularity Particles <0.250mm.

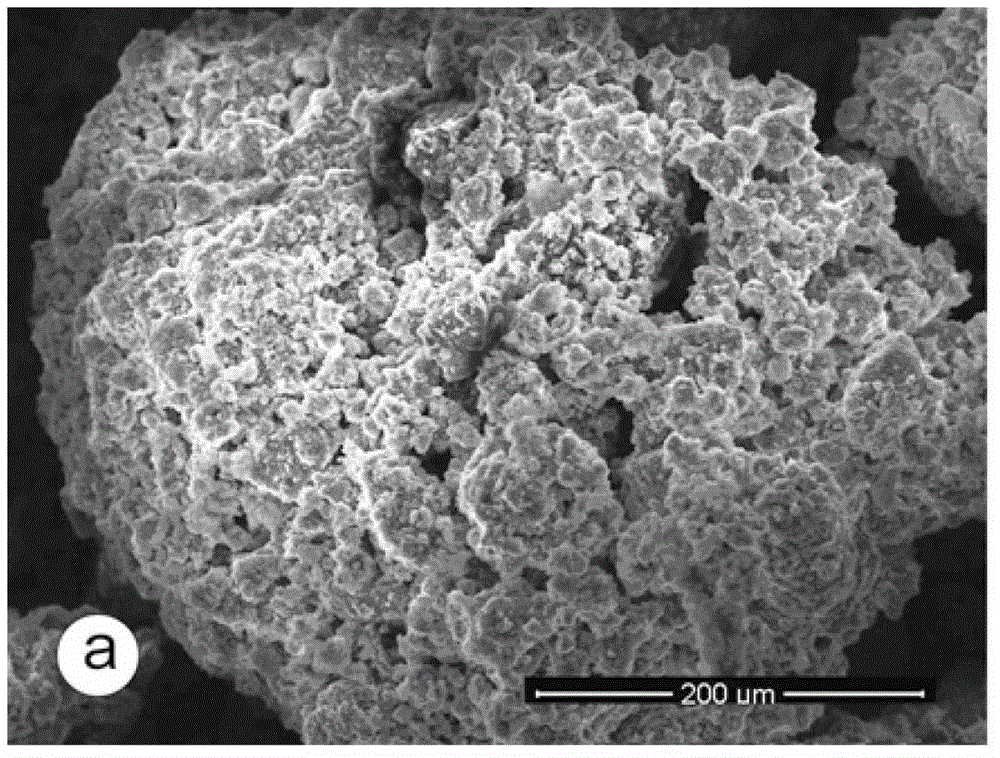

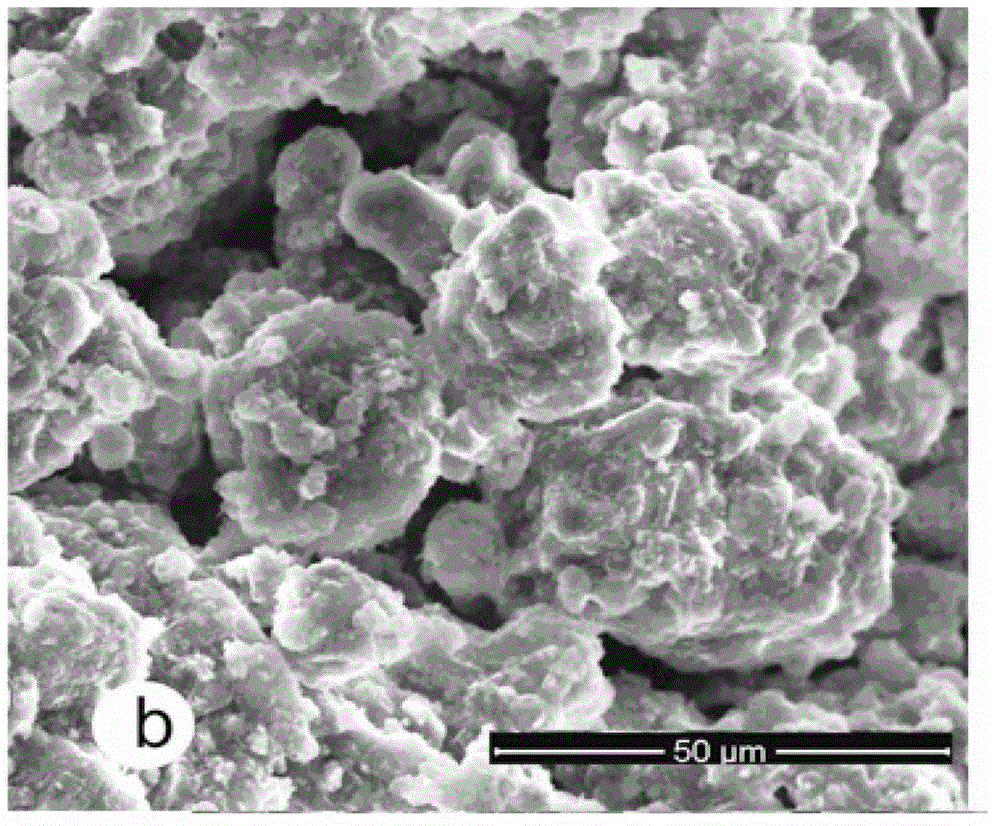

[0043] The obtained particles are detected by scanning electron microscopy, such as figure 1 , fi...

Embodiment 3

[0045] 1. Red mud composite material ingredients

[0046] Red mud 60g; cementing material: plaster of paris 3g, Portland cement 5g; inorganic additives: acid activated biochar 6g, dipotassium hydrogen phosphate 18g; compost 8g, water and pore former op, where the water quality is the total dry material (Red mud, cement, inorganic additives, compost) 50% of the mass, and the pore former op mass is 0.1% of the water mass.

[0047] 2. Preparation of red mud composite material

[0048] First mix the red mud and the cementitious material, then add the aqueous solution containing the pore former op, mix and stir evenly, let it stand for 1.5 minutes, then add the inorganic additives and compost, mix and stir evenly, then let it stand for 10 minutes, put the mixture into Squeeze granulation in a swing granulator, rotate at 65 rpm, pass through a 60-mesh sieve, and get the granularity Particles <0.250mm.

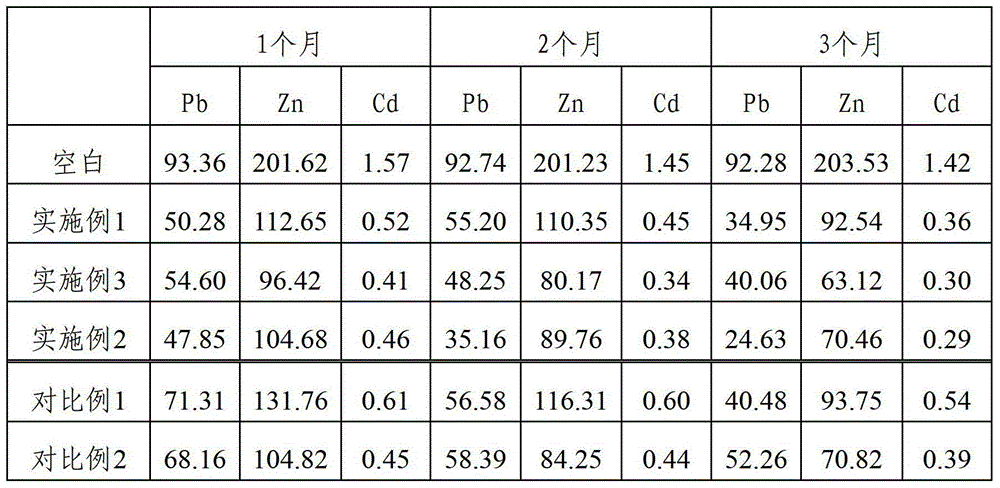

[0049] In addition, using the same amount of red mud raw material and the same amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com