Spinning heating device

A heating device and external heating technology, applied in lighting and heating equipment, metal processing equipment, combustion methods, etc., can solve problems such as uneven heating, low efficiency, and magnesium combustion, so as to reduce heat loss, save time and cost, and improve The effect of spinning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

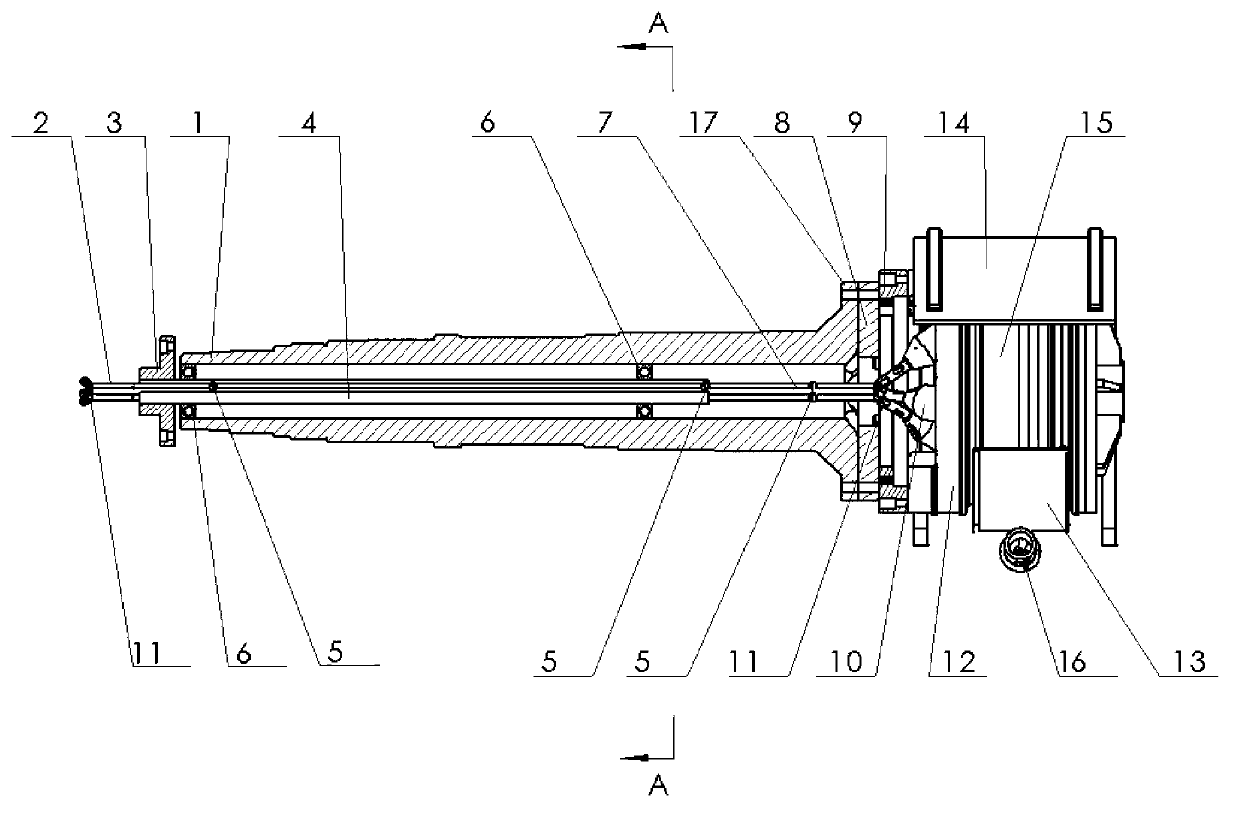

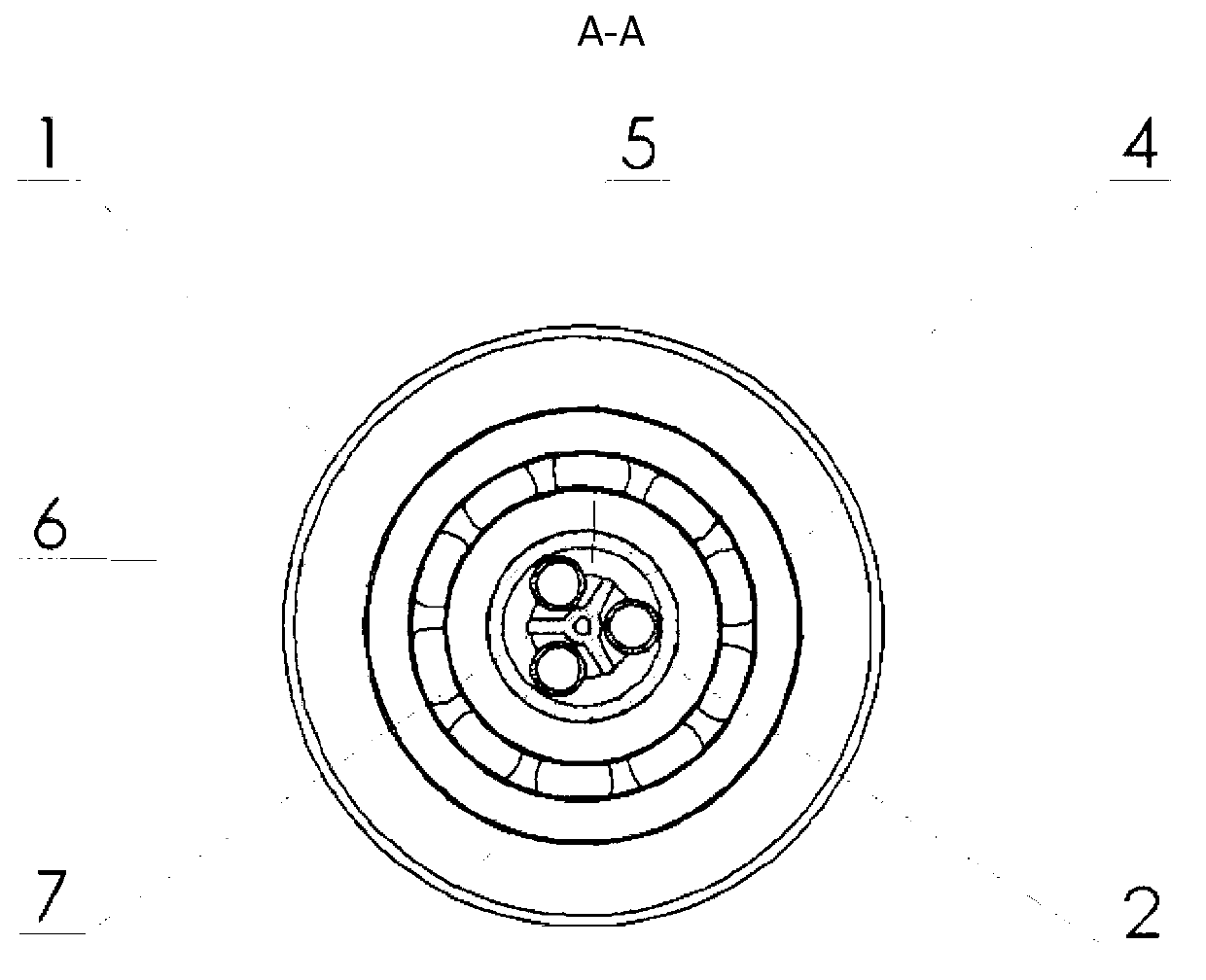

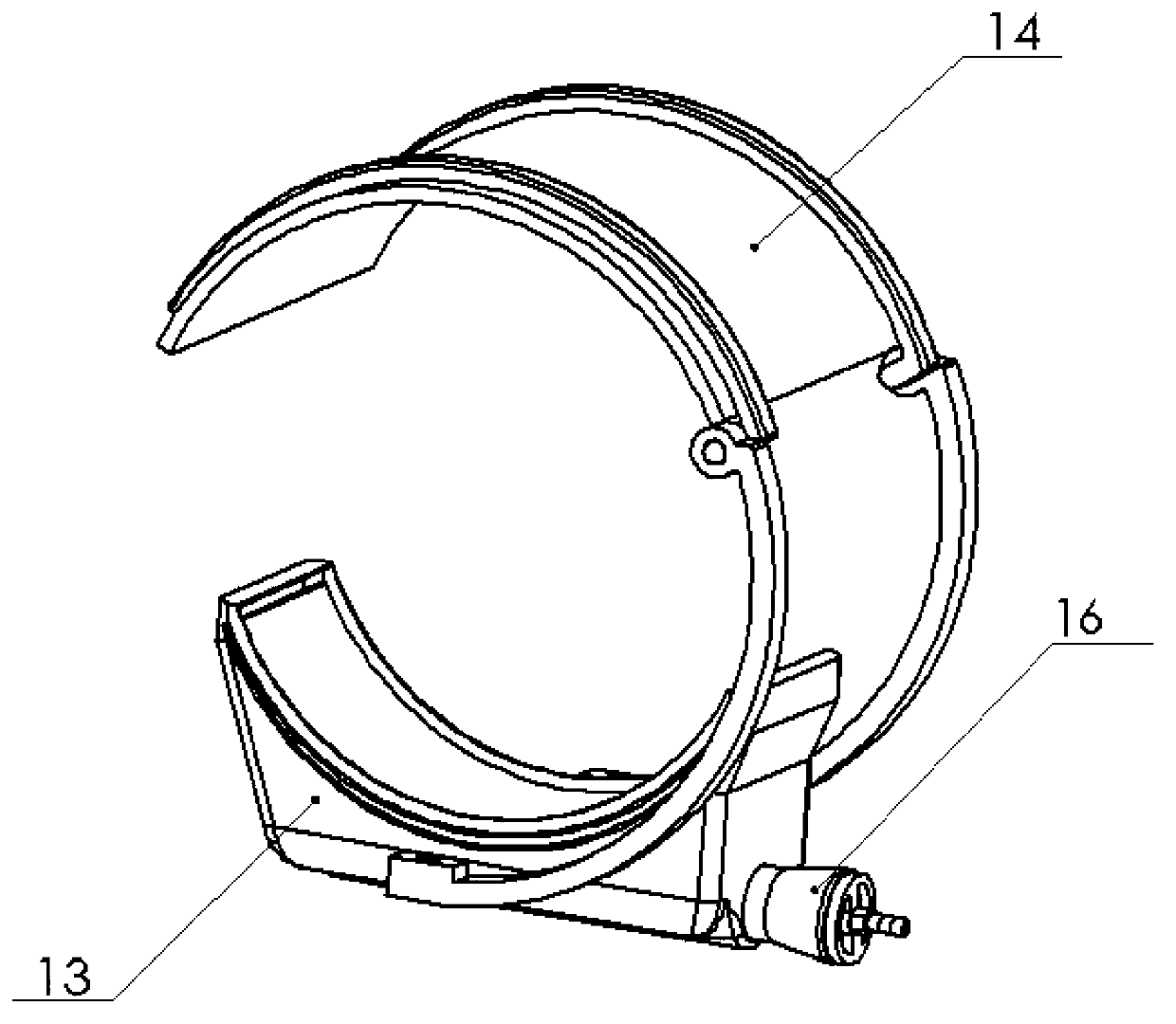

[0028] Please also see Figure 1 to Figure 3 .

[0029] This embodiment provides a spinning heating device, including an internal gas heating device and an external heating and heat preservation device, the internal gas heating device is arranged inside the spinning mold, and the external heating and heat preservation device is arranged outside the spinning blank; wherein :

[0030] The internal gas heating device includes a main shaft, a gas delivery pipe group and a three-leaf fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com