Welding-free circular pipe forming method

A forming method, a welding-free technology, applied in forming tools, perforating tools, applications, etc., can solve the problems of rising labor costs, increasing mold costs, error accumulation, etc., and achieve the effects of reduced production costs, simple molds, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] A method for forming a circular tube without welding, comprising the steps of:

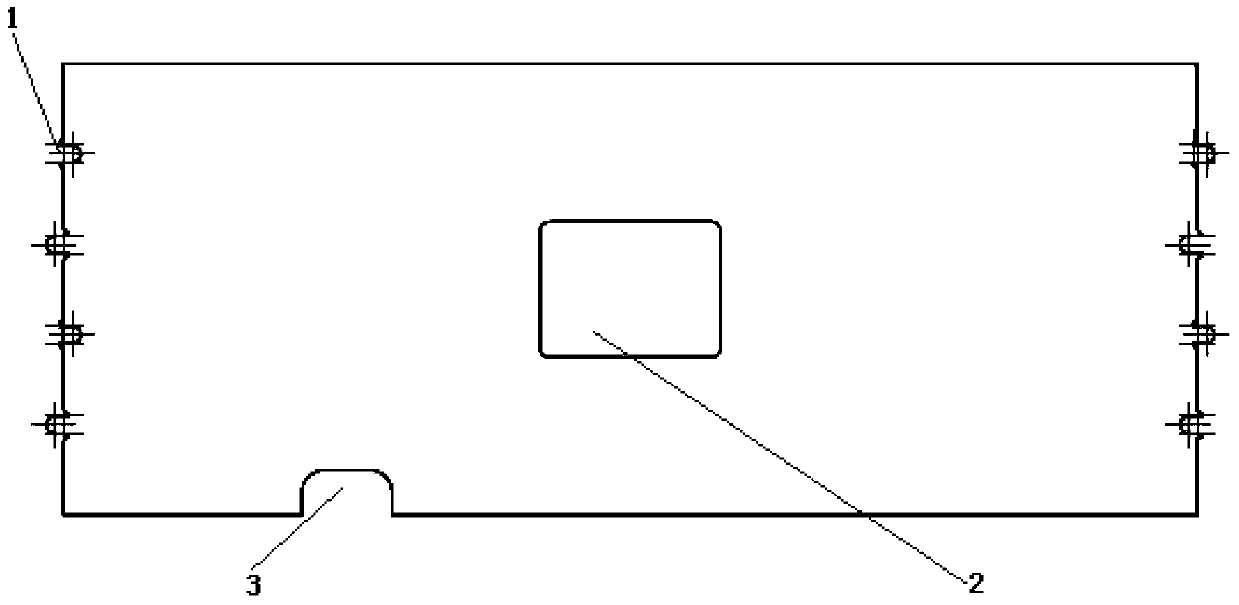

[0020] Take the stamped flat plate and use a punch to form it once. The formed product will punch out four buckles 1 on the two short sides of the flat plate, punch a square hole 2 in the center of the flat plate, and punch out a square hole 2 in the lower long side of the flat plate. punch out a semicircle 3, such as figure 1 shown;

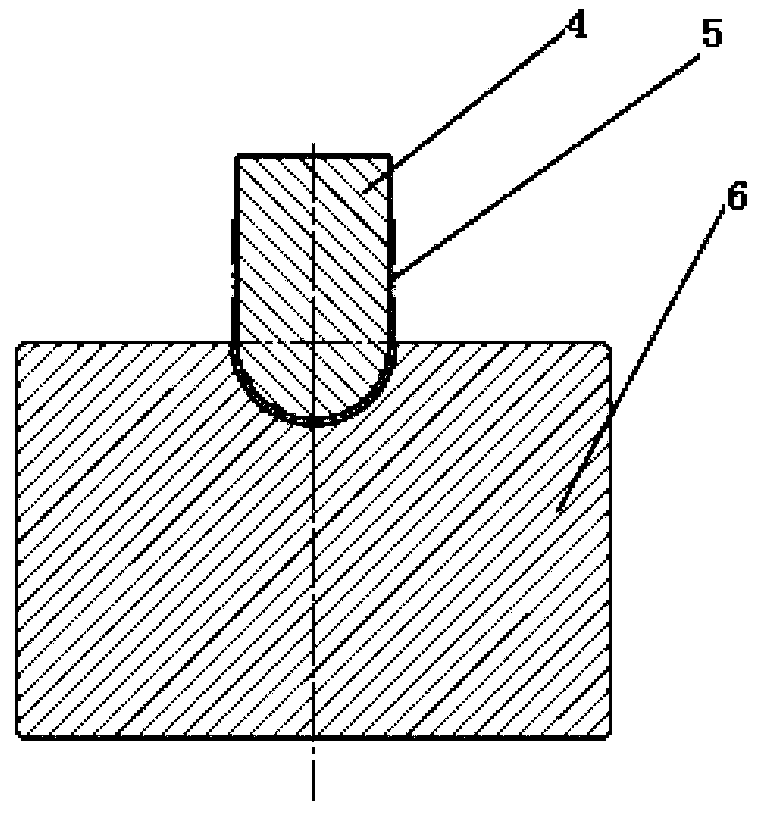

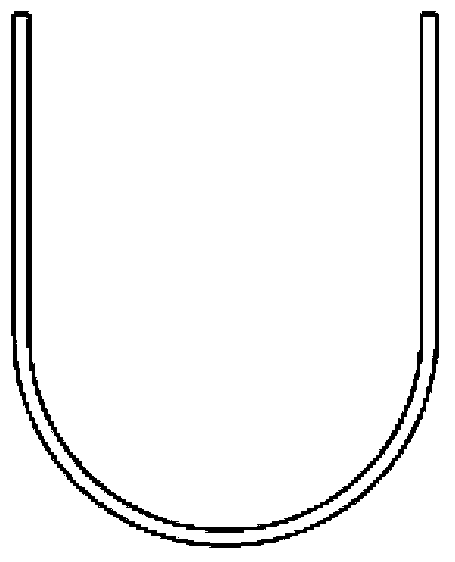

[0021] The first-time stamping and forming device is used for the first-time stamping and forming of the once-formed product, and the formed product is a flat plate with a semicircle in the middle, such as figure 2 As shown; the stamping forming device for the first time is composed of an upper die 4 of the stamping forming device for the first time and a lower die 5 of the stamping forming device for the first time, and a semicircular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com