Method for adjusting addition of flocculants in stoving neutral juice based on zeta potential value

A flocculant and potential value technology, which is applied in the purification of sugar juice, sugar production, sucrose production, etc., can solve the problems that affect the quality of white sugar products, the quality of clear juice is low, and the flocculation and clarification effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

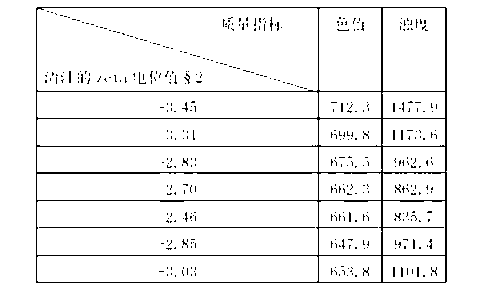

[0038] A method for adjusting the addition of flocculants in sulfur-fumed neutralized juice based on the zeta potential value of clear juice after flocculation and clarification of sulfur-fumed neutralized juice

[0039] In the clarification process of the existing sugar-making process, the selection of step A. the type of flocculant is carried out first:

[0040] ①When the zeta potential value of the clear juice after flocculation and clarification of the sulfur-fumed neutralized juice is negative, a cationic flocculant is used;

[0041] ② When the zeta potential value of the clear juice after flocculation and clarification of the sulfur-fumed neutralized juice is positive, an anionic flocculant is used.

[0042] Then proceed to B. The choice of the amount of flocculant, every 30 minutes, sample the clear juice after flocculation and clarification of sulfur-fumed neutralized juice, and measure the zeta potential value of the clear juice after flocculation and clarification o...

Embodiment 2

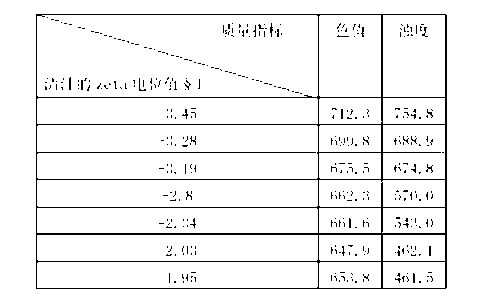

[0046] A method for adjusting the addition of flocculants to sulfur-fumed neutralized juice based on zeta potential value, the method uses the initial zeta potential value of sulfur-fumed neutralized juice as the basis for adding flocculants to sulfur-fumed neutralized juice:

[0047] The basic steps of the method are the same as those of step A in the first embodiment. The choice of flocculant type is to insert a rubber tube from the inlet hole of the sedimentation tank in the clarification process of the existing sugar making process, extract the sulfur-fumed neutralized juice once every 30 minutes, and measure its initial zeta potential value:

[0048] ①When the initial zeta potential value of sulfur-fumed neutralized juice is negative, use cationic flocculant;

[0049] ② When the initial zeta potential value of the sulfur-fumed neutralized juice is positive, an anionic flocculant is used.

[0050] In the first and second embodiments of the present invention, the cationic ...

Embodiment 3

[0053] A method for adjusting the proportioning ratio of flocculant added in sulfur-fumed neutralized juice based on the zeta potential value of the clear juice after flocculation and clarification of sulfur-fumed neutralized juice, the method is based on the zeta potential value of the clear juice after flocculation and clarification of sulfur-fumed neutralized juice Based on this, it guides the compounding of different flocculants to form a composite flocculant, which is easy to compress the electric double layer, and can quickly reduce the zeta potential of the clear juice after flocculation and clarification of the sulfur-fumed neutralized juice by means of electric neutralization and adsorption. The compound flocculant is the best compound;

[0054] The composite flocculant comprises a composite flocculant composed of polyaluminum chloride and chitosan or a composite flocculant composed of cationic polyacrylamine and polyaluminum chloride;

[0055] In the composite floccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com