Method for lateral displacement resistance of full-fastener-type steel tube scaffolds

A scaffolding and anti-side-shifting technology, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve the problems of low bearing capacity, small step distance of horizontal rods, and low utilization rate of steel pipe strength, so as to improve the overall stability The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

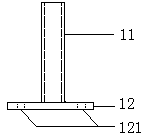

[0017] The method of the present invention is based on the standard structural requirements and construction methods of the traditional full-hole fastener-type steel pipe scaffolding (refer to JGJ130-2011 safety technical specifications for fastener-type steel pipe scaffolding in building construction, etc.), adding anti-side movement diagonal braces, specifically The implementation mode is: take the building below 3 meters of general story height as an example to illustrate, as the full hall fastener type steel pipe scaffolding of formwork support, set up two steps of equal steps. In the horizontal and vertical directions of the central part of the first floor, a row of diagonal braces is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com