Integrated cold-formed thin-walled steel plate constraint profile steel special-shaped column and machining method thereof

A technology of cold-formed thin-walled steel and cold-formed thin-walled steel, which is applied in the direction of columns, pillars, pier columns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

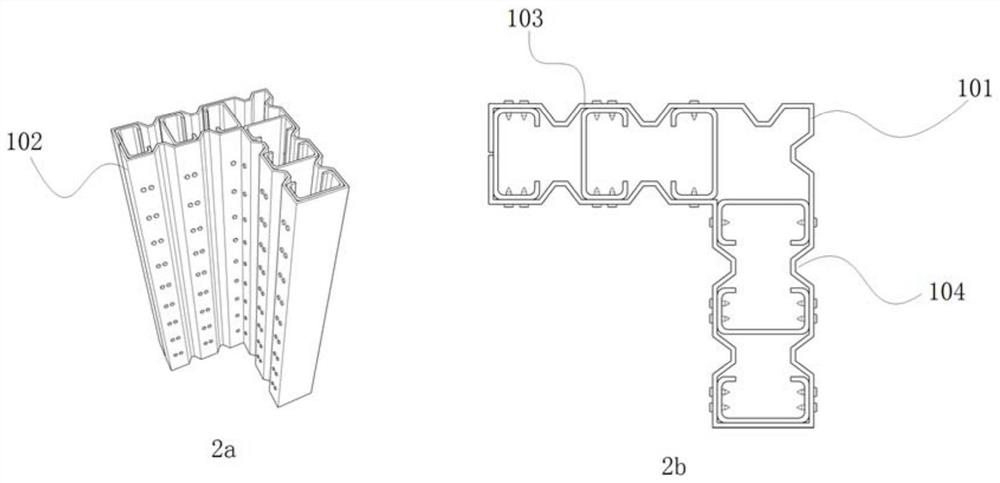

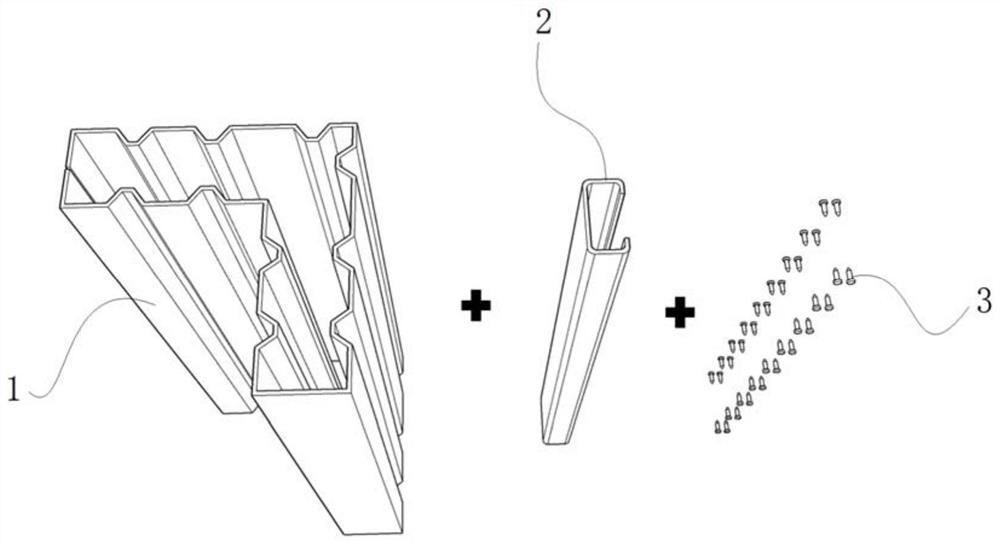

[0037] This embodiment discloses an integrated cold-formed thin-walled steel plate-constrained shaped steel special-shaped column, which includes a cold-formed thin-walled special-shaped steel pipe column 1 and a built-in cold-formed thin-walled steel member 2 .

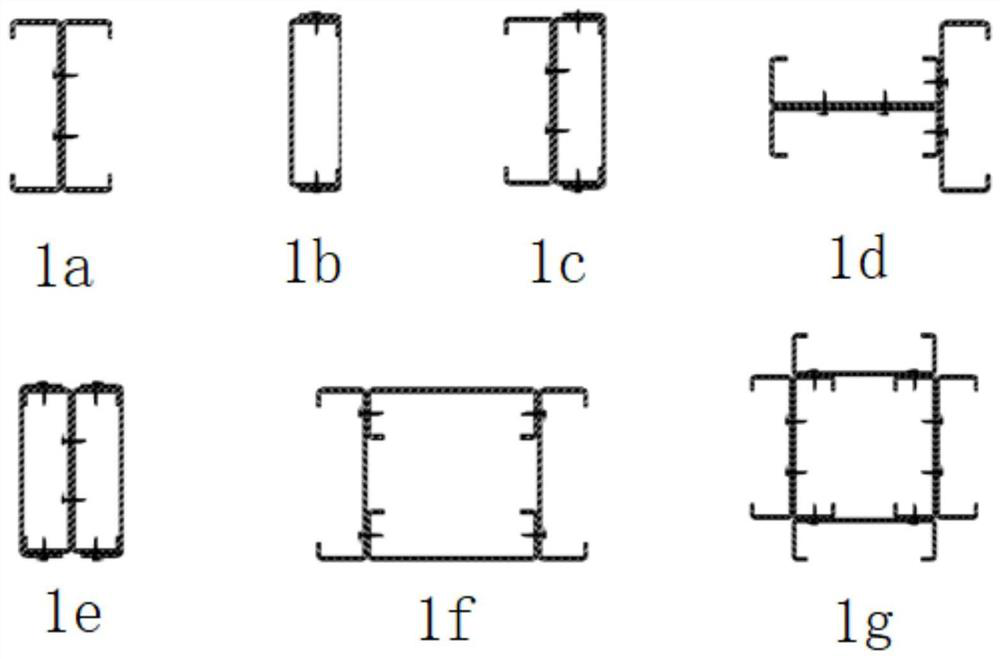

[0038] The cold-formed thin-wall special-shaped steel pipe column 1 is a cold-formed special-shaped hollow steel pipe. The overall cross-section of the cold-formed thin-walled special-shaped steel pipe column 1 is L-shaped, T-shaped or cross-shaped.

[0039] The cold-formed thin-wall special-shaped steel pipe column 1 with L-shaped cross-section as a whole includes an L-shaped core side plate 101 and two trough-shaped column legs 102 . The L-shaped core side plate 101 is L-shaped steel as a whole. The channel-shaped column limb 102 is a channel-shaped section steel as a whole. The channel section includes a web and two flange plates. The flange plate is a bent corrugated plate. The flange plate includes a plurali...

Embodiment 2

[0045] This embodiment discloses an integrated cold-formed thin-walled steel plate-constrained shaped steel special-shaped column, which includes a cold-formed thin-walled special-shaped steel pipe column 1 and a built-in cold-formed thin-walled steel member 2 .

[0046] The cold-formed thin-wall special-shaped steel pipe column 1 is a cold-formed special-shaped hollow steel pipe. The overall cross-section of the cold-formed thin-walled special-shaped steel pipe column 1 is L-shaped, T-shaped or cross-shaped.

[0047] see figure 2 A cold-formed thin-walled special-shaped steel pipe column 1 with an overall L-shaped cross section includes an L-shaped core side plate 101 and two trough-shaped column legs 102 . The L-shaped core side plate 101 is L-shaped steel as a whole. The channel-shaped column limb 102 is a channel-shaped section steel as a whole. The channel section includes a web and two flange plates. The flange plate is a bent corrugated plate. The flange plate inc...

Embodiment 3

[0053] see Figure 8 with Figure 9 , this embodiment provides a thin-walled steel structure residential system using the above-mentioned integrated cold-formed thin-walled steel plate constrained profiled steel special-shaped column. The integrated cold-formed thin-walled steel plate constrained shaped steel special-shaped column is welded to the cold-formed thin-walled composite beam 4. The floor keel 5 and the cold-formed thin-walled composite beam 4 are connected by self-tapping screws. The upper integrated cold-formed thin-walled steel plate constrained profiled steel special-shaped column and the lower integrated cold-formed thin-walled steel plate constrained profiled steel profiled column can be butted together. Tap screw connections. The integrated cold-formed thin-walled steel plate constrained steel special-shaped column is used for load-bearing and lateral resistance. The space layout is flexible, and it is easy to form a large space. The indoor structural compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com