Novel composite rod with built-in hollow bamboo pipe

A technology of composite rods and bamboo tubes, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve problems such as unsatisfactory bonding force, easy cracking in the ring direction, uneven bamboo tubes, etc., and achieve Guaranteed bearing capacity, improved stable bearing capacity, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

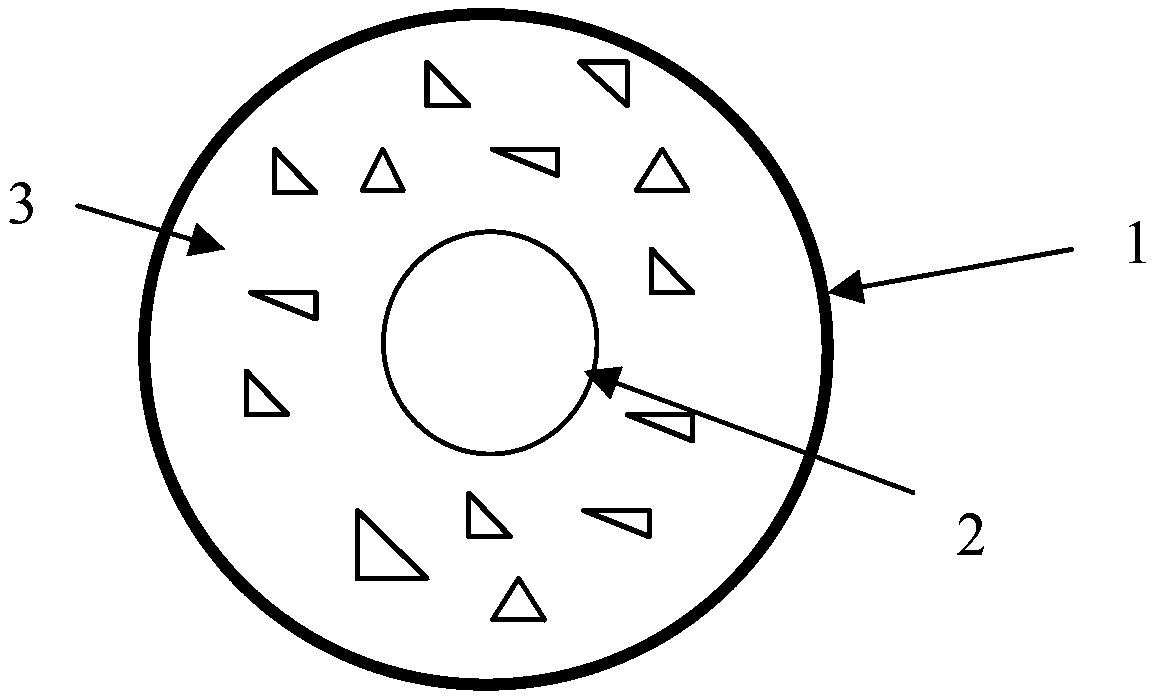

[0022] Such as figure 1 Shown, the present invention comprises GFRP pipe 1, be located at the bamboo pipe 2 in GFRP pipe 1 and fill in the concrete 3 layers between GFRP pipe 1, bamboo pipe 2; Described bamboo pipe 2 is natural hollow bamboo pipe 2 , The GFRP tube 1 is provided with one or more bamboo tubes 2 , the bamboo tubes 2 are equal to the GFRP tube 1 or shorter than the GFRP tube 1 . Using the bamboo tube 2 as the inner tube of the hollow interlayer GFRP pipe 1 concrete 3, which is wrapped in the concrete 3, can avoid the natural unevenness of the bamboo tube 2 and the problem of easy cracking in the ring direction, so that the natural bamboo tube 2 can be used reasonably. On the premise of ensuring sufficient strength of the combined rod, the cost can be effectively reduced. Concrete 3 is filled between the bamboo tube 2 and the outer GFRP tube 1 to avoid cracking of the bamboo tube 2 and local instability of the GFRP tube 1 inward. The outward protrusion of the bam...

Embodiment 2

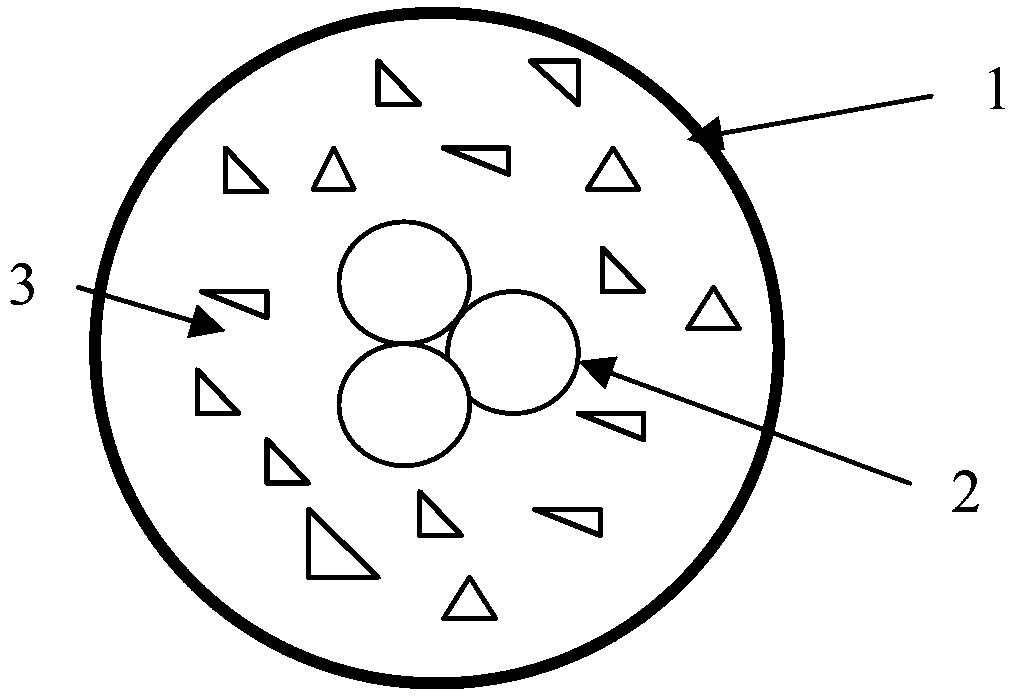

[0030] Such as figure 2 As shown, the same as the first embodiment will not be repeated, the difference is: the GFRP tube 1 is provided with three or more than three bamboo tubes 2 . According to actual needs, the corresponding number of bamboo tubes 2 can be selected to effectively reduce the weight of the combined rod.

[0031] In order to improve the integrity, gaps are placed between the bamboo tubes 2 to fill the concrete 3 between the bamboo tubes 2 . On the premise of effectively improving the integrity, increase the strength.

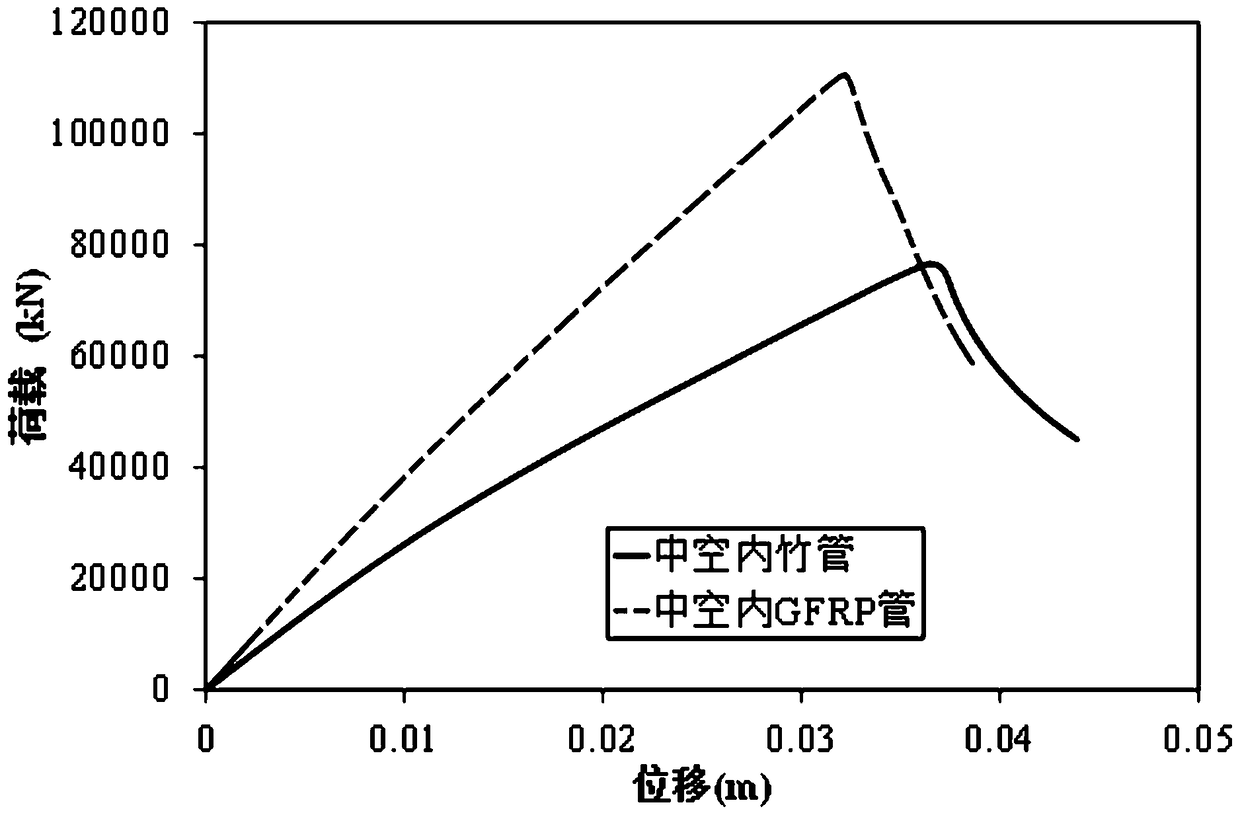

[0032] The following is an analysis of the hollow bamboo tube 2 and the hollow GFRP tube 1 in the combined rod: through the finite element calculation and comparison of the hollow inner bamboo tube 2 and the hollow inner GFRP tube 1 of the same size, the failure modes of the two are the same, as image 3 As shown, the load-displacement curves of the hollow inner bamboo tube 2 and the hollow inner GFRP tube 1 are compared, and the bearing capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com