Hydraulic energy-saving drill pipe transportation equipment

A conveying equipment and hydraulic technology, applied in the field of hydraulic energy-saving drill pipe conveying equipment, can solve the problems of insufficient automation, high manufacturing cost, and potential safety hazards, so as to reduce manual participation, improve conveying efficiency, and reduce safety. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

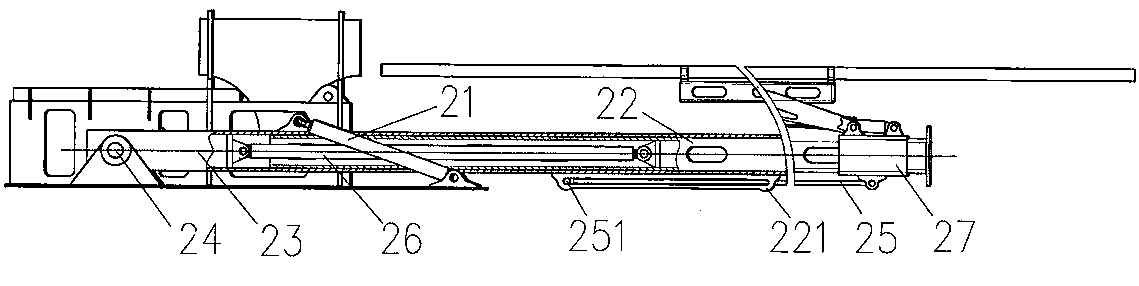

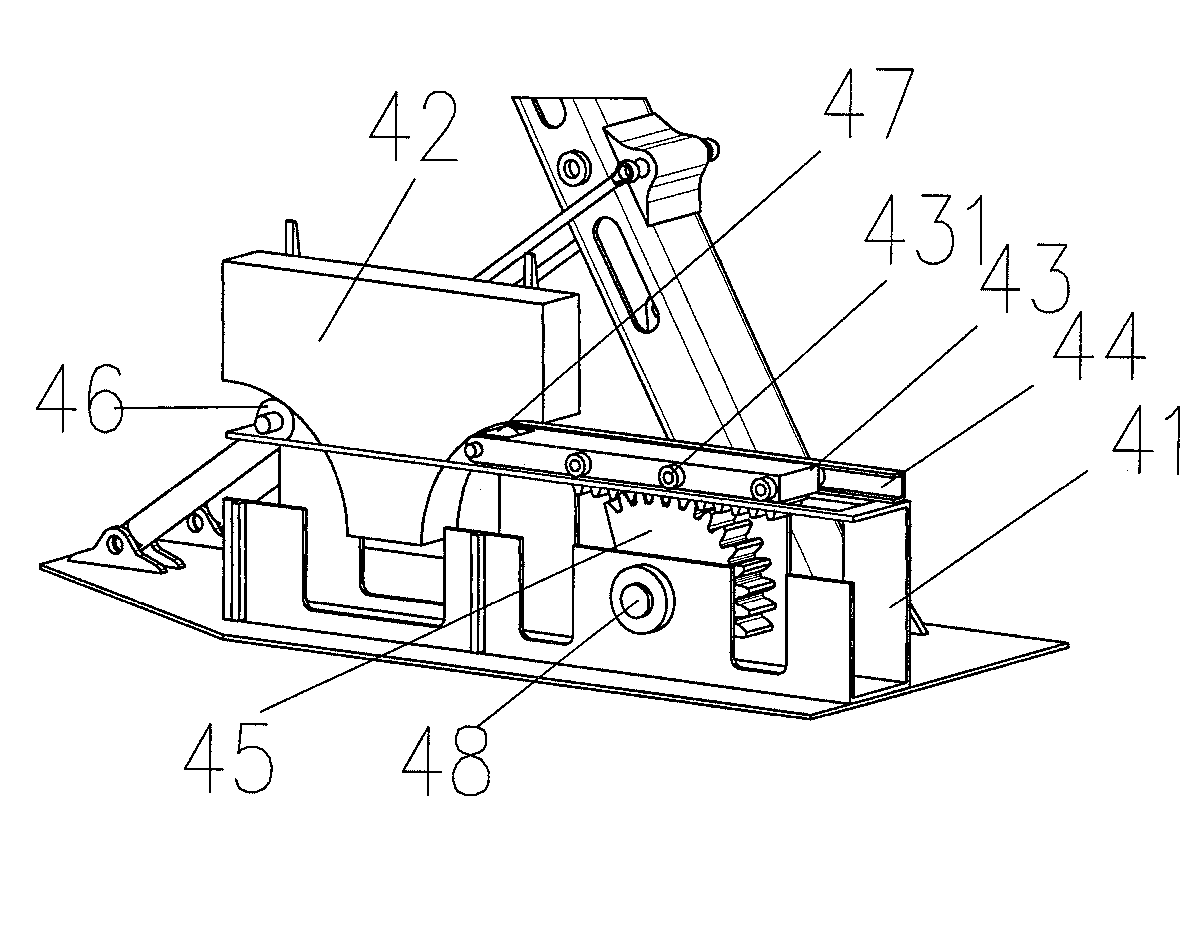

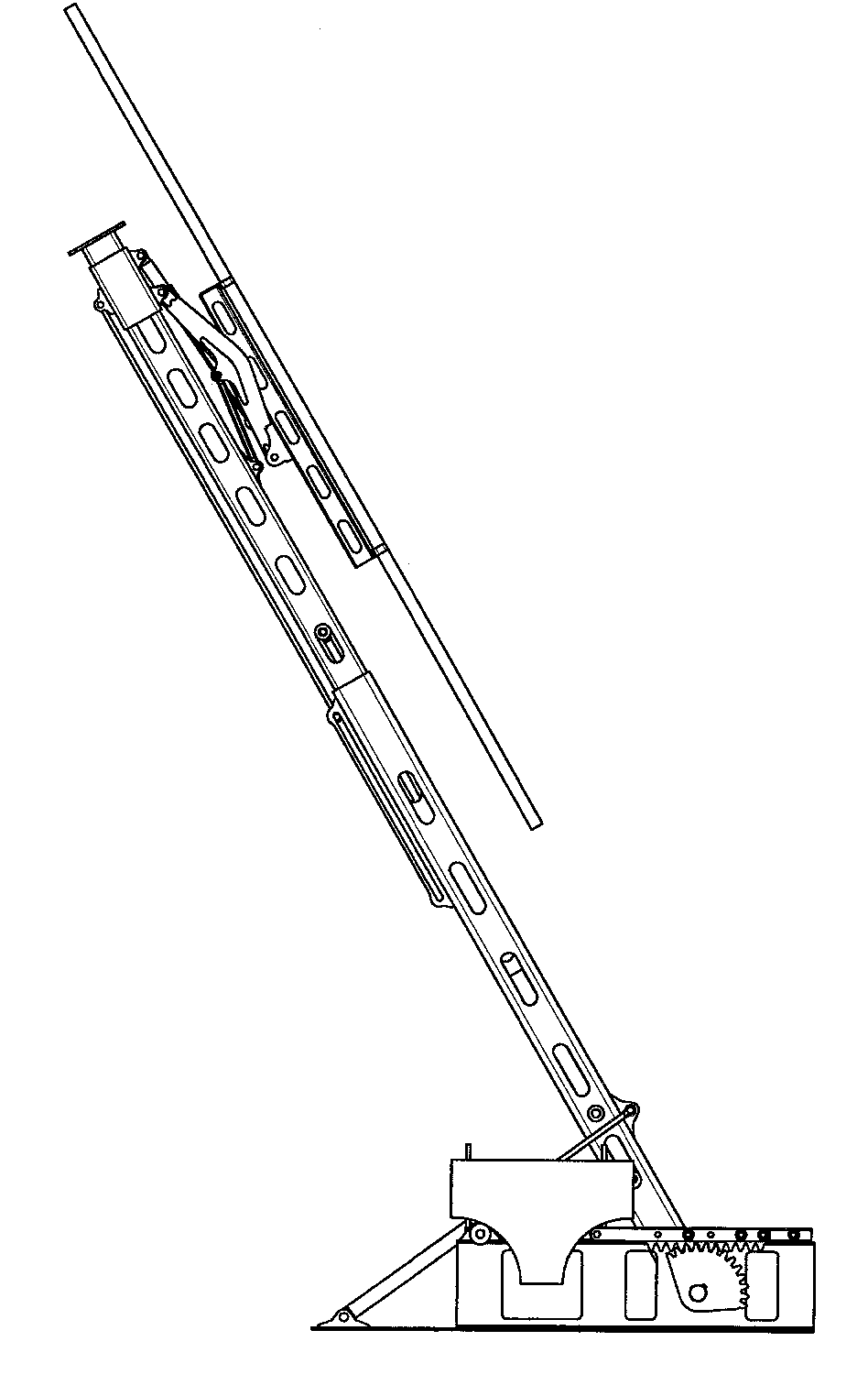

[0028] see figure 1 As shown, this embodiment is composed of a base 1, a lifting module 2, a rod feeding module 3 and an energy-saving module 4, as figure 2 As shown, the lifting module 2 is composed of a lifting cylinder 21, a lifting upper bracket 22, a lifting lower bracket 23, a lifting support shaft 24, a pull rod 25, a bracket telescopic cylinder 26 and a moving sliding sleeve 27. The lifting cylinder 21 One end of the lifting cylinder 21 is hinged with the base 1, and the other end of the lifting cylinder 21 is hinged with the middle part of the lifting lower bracket 23; the bottom end of the lifting lower bracket 23 is hinged with the base 1 through the lifting support shaft 24; one end of the bracket telescopic cylinder 26 It is hinged with the lifting lower bracket 23, and the other end of the bracket telescopic oil cylinder 26 is hinged with the lifting upper bracket 22; the back side of the lifting upper bracket 22 is provided with a pull rod slideway 221, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com