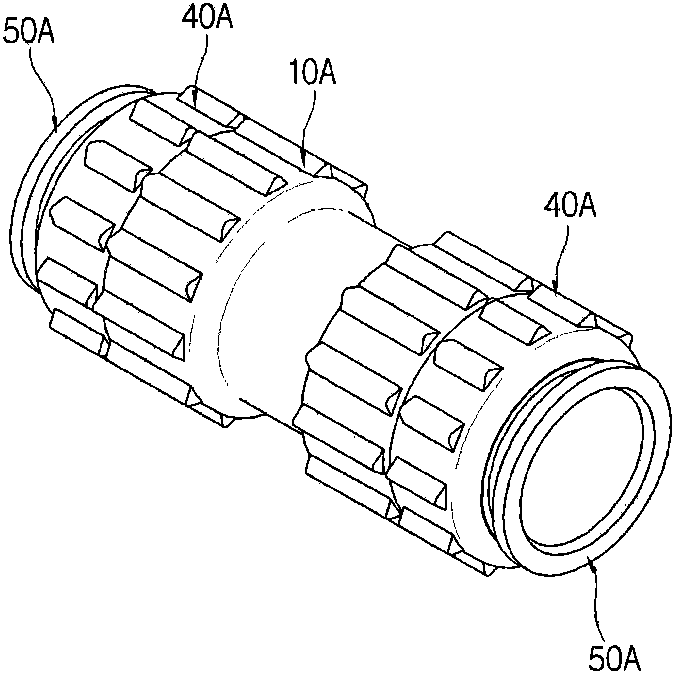

One touch-type pipe connection apparatus

A connection device and piping technology, which is applied to mechanical equipment, couplings, etc., can solve the problems of inconvenient maintenance work, inability to ensure the water tightness and fixing force of the connection between the pipes, and difficulty in separating the pipe bodies, and achieve low production costs. , Shorten the time of piping construction and maintenance work, and prevent water leakage accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

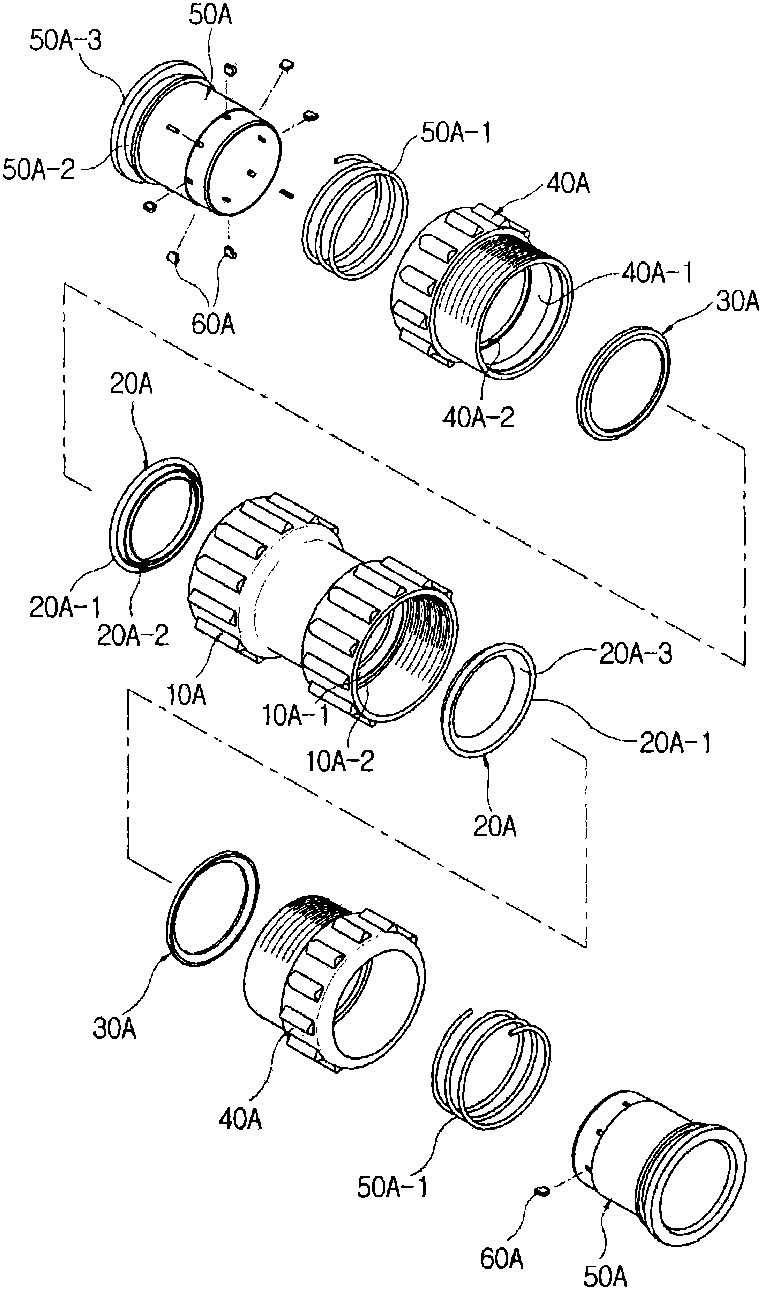

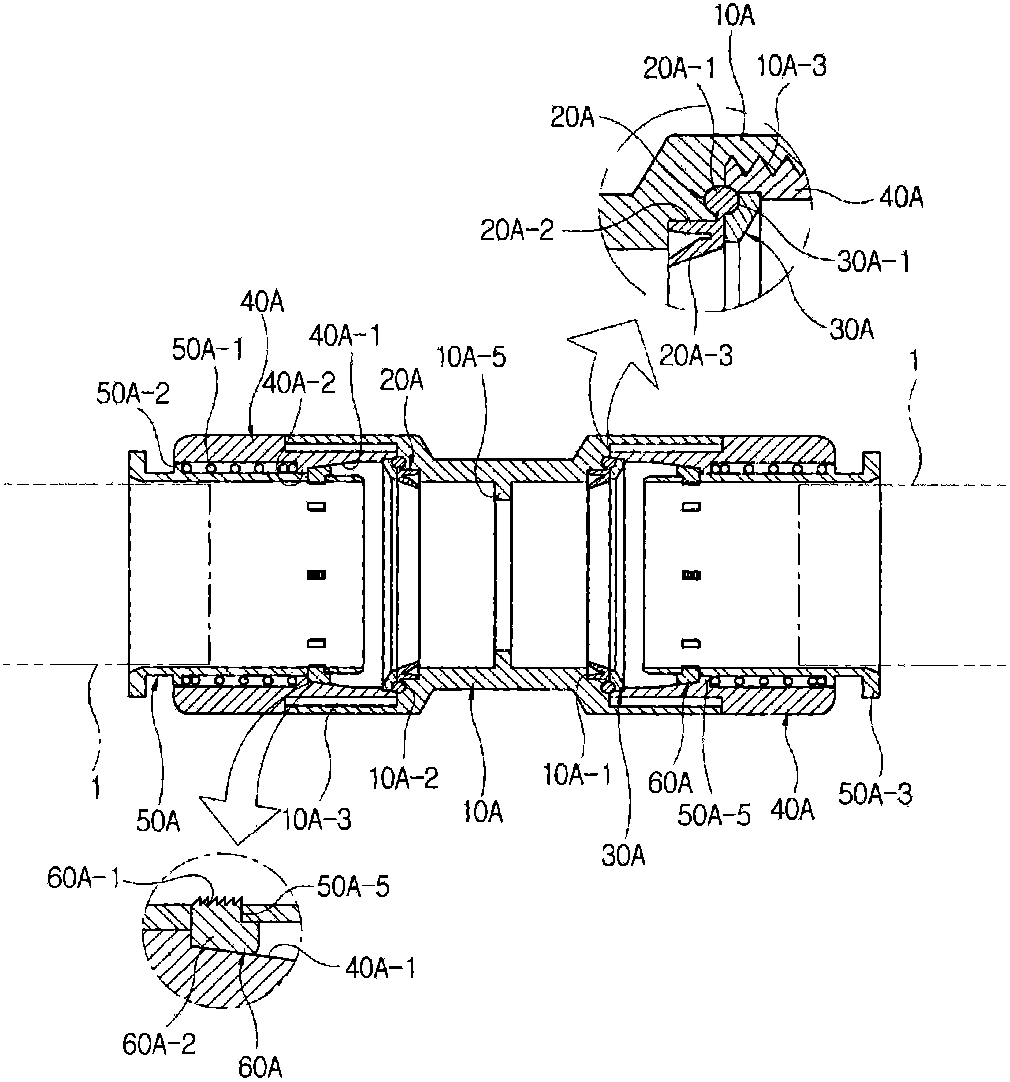

[0032]The present invention is characterized in that it includes: a first main body member having a size that can be inserted into a pipe, and having stepped portions formed in the horizontal direction on both sides of the inner peripheral surface based on the central portion, and facing in a direction perpendicular to the stepped portion. The first insertion groove arranged, and the screw thread formed horizontally from the first insertion groove; the first watertight member is provided with an extrusion protrusion arranged along the first insertion groove, and is integrally extended from the extrusion protrusion. The placing piece arranged on the stepped portion, and the elastic piece extended obliquely from the end of the placing piece toward the central side of the first main body member and closely attached to the outer peripheral surface of the pipe; the annular support member is formed to be closely attached to the The pressurizing groove of the extrusion protrusion; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com