Paper for daily use

A technology of household paper and surface paper, which is applied in paper, papermaking, special paper, etc., can solve the problem of high investment cost of household paper, and achieve the effect of low price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

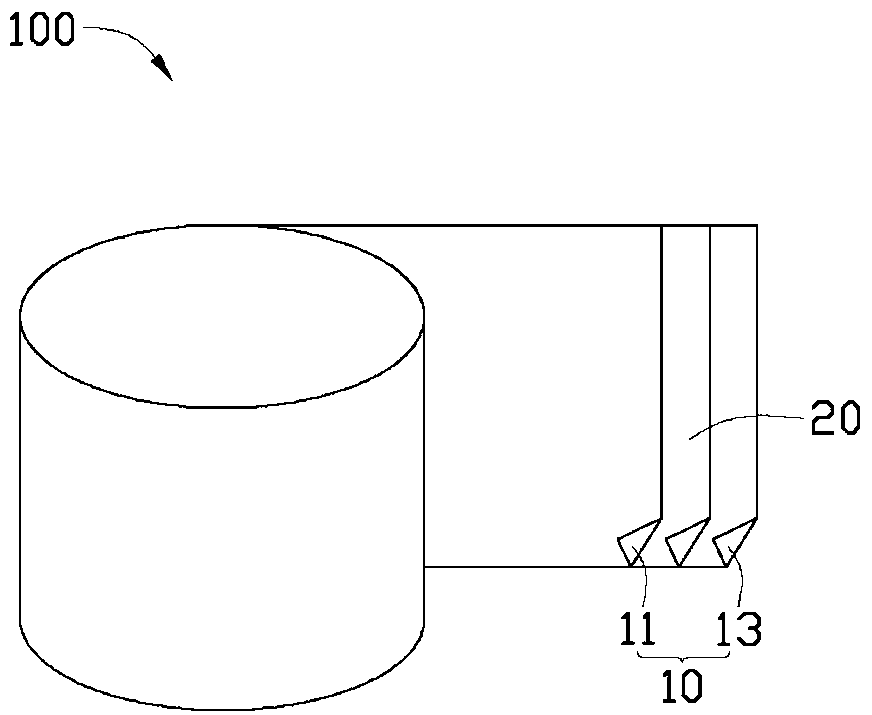

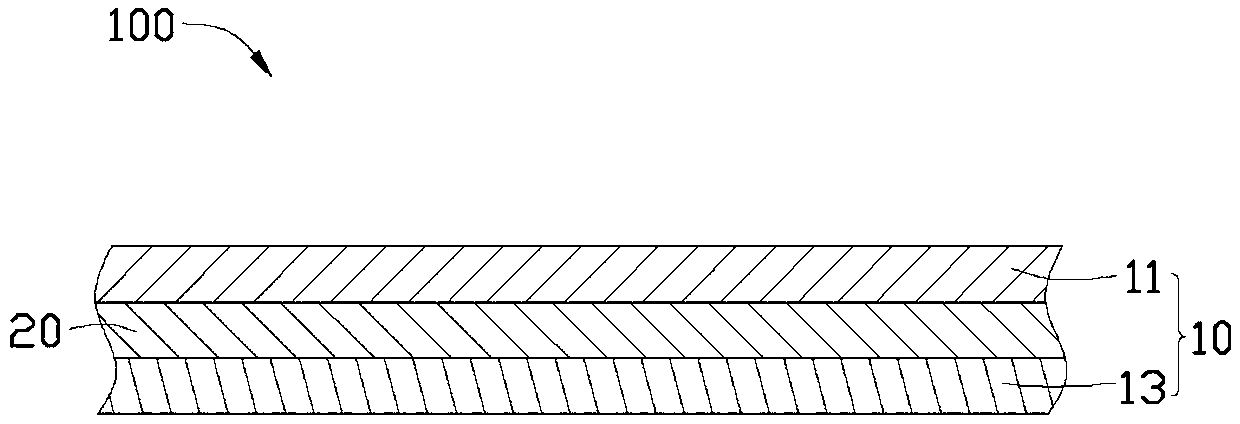

[0022] In this embodiment, the upper surface paper 11 and the lower surface paper 13 of the surface paper 10 are both made with a general fiber ratio, specifically 20% long-fiber virgin wood pulp + 80% short-fiber virgin wood pulp.

[0023] In this embodiment, the core paper 20 has a single-layer structure, and the formula adopted is 15% wollastonite fiber + 15% long-fiber virgin wood pulp + 70% short-fiber virgin wood pulp.

Embodiment 2

[0025] In this embodiment, the upper surface paper 11 and the lower surface paper 13 of the surface paper 10 are both made with a general fiber ratio, specifically 30% long-fiber virgin wood pulp + 70% short-fiber virgin wood pulp.

[0026] In this embodiment, the core paper 20 has a single-layer structure, and the formula adopted is 5% polypropylene fiber + 15% long-fiber virgin wood pulp + 80% short-fiber virgin wood pulp.

Embodiment 3

[0028] In this embodiment, the upper surface paper 11 and the lower surface paper 13 of the surface paper 10 are made with a general fiber ratio, specifically 40% short-fiber virgin wood pulp + 60% bamboo pulp.

[0029] In this embodiment, the core paper 20 has a single-layer structure, and the formula adopted is 20% sepiolite fiber + 20% long-fiber virgin wood pulp + 60% short-fiber virgin wood pulp.

[0030] During the use of the multi-layer household paper 100 prepared in Example 1, Example 2 and Example 3, the surface paper 10 is in direct contact with the skin of the user, so the surface paper 10 is required to be softer. However, the core paper 20 does not need a higher hand feeling requirement. Combine the surface paper 10 and the core paper 20 to give full play to the functions of the surface paper 10 and the core paper 20, which not only meets the requirements for the feel of use, but also meets the requirements for strength during use, and can effectively reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com