Spiral-flow type smoke purifying process unit

A technology for dust purification and process equipment, which is used in combination equipment, chemical instruments and methods, and dispersed particle separation. , Economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

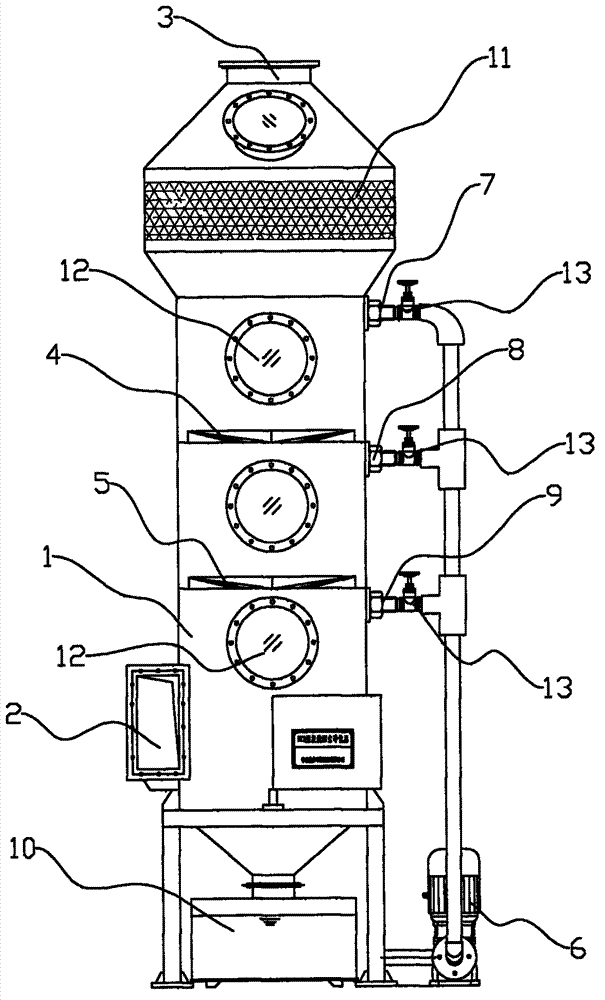

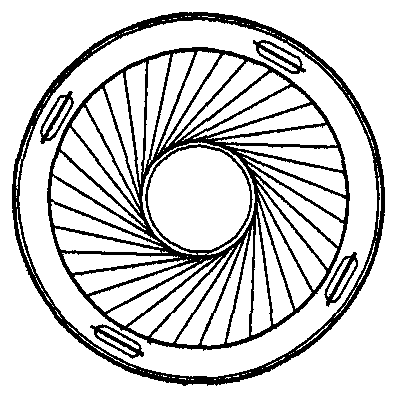

[0012] refer to figure 1 , figure 2 , a kind of cyclone type soot purification process device of the present invention, comprises tower body 1, and tower body 1 side is provided with air inlet 2, and its top is provided with air outlet 3, and described tower body 1 is installed with first, second The first and second turbulent swirl sheets 4, 5 are located between the air inlet 2 and the air outlet 3 (according to the smoke concentration, the number of turbulent swirl sheets can be appropriately increased ), the air inlet 2 is provided with a centrifugal vortex air inlet box, and the tower body 1 is externally connected with an atomizer, and the atomizer includes an atomizing pump 6, and the atomizing pump 6 is connected to the first, second, second Three atomizing nozzles 7, 8, 9, wherein the first atomizing nozzle 7 is located above the first turbulent swirl sheet layer 4, and the second atomizing nozzle 8 is located between the first and second turbulent swirl sheet layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com