Tech. for treating waste water of fruit juice processing

A technology for processing waste water and treatment process, which is applied in the direction of aerobic process treatment, biological water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of unsatisfactory treatment effect and difficult discharge or reuse of effluent water quality. Achieve remarkable removal effects, save engineering investment and operating costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

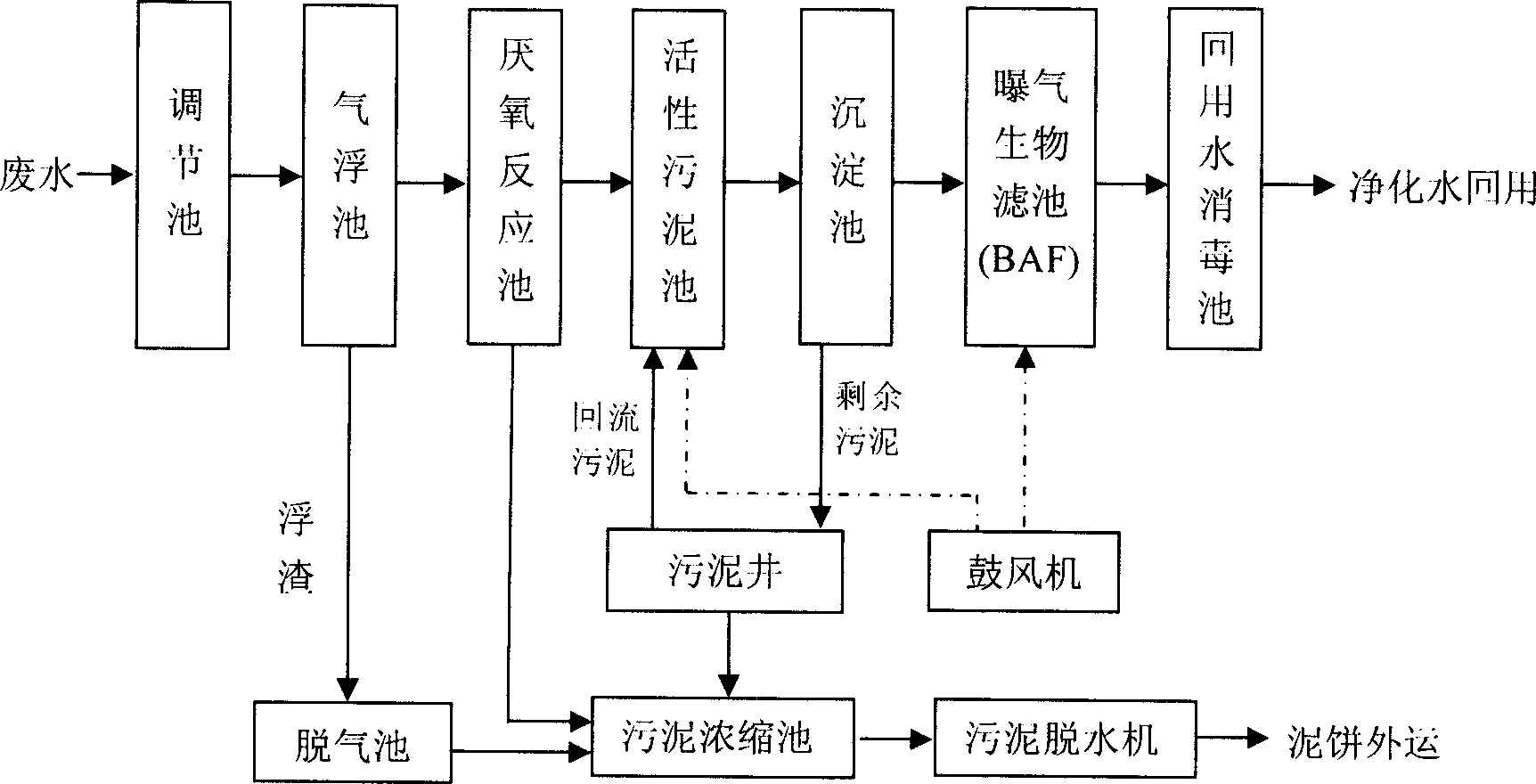

[0022] figure 1 It is a flow chart of the fruit juice processing wastewater treatment process of the present invention, which specifically includes the following process steps:

[0023] 1. The wastewater first flows into the regulating pool, which is equipped with a stirrer, and the wastewater is fully stirred to achieve the balance of water quality and quantity;

[0024] 2. The water treated in step 1 enters the air flotation tank, and is degummed and suspended by the air flotation process. In this embodiment, the air flotation degumming process adopts a direct ultra-fine air flotation machine, and the hydraulic retention time is generally 0.5 to 1 hour. Directly remove more than 80% of suspended matter and about 40% of organic matter;

[0025] 3. The water treated by the air flotation process enters the anaerobic reaction tank, and the anaerobic reaction tank is equipped with an upflow anaerobic sludge bed reactor, which further reduces the content of organic matter and sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com