Method for controlling rotation of continuous casting deburring machine

A deburring machine and burr technology are applied in the control field of the rotation of the deburring machine, which can solve the problems of lowering the talent rate of casting billets, lowering the quality of steel production, unclean removal of the burrs of casting billets, etc., so as to improve the quality of steel production and increase talent. efficiency, and the effect of reducing the amount of manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. It should be understood that the following examples are only used to illustrate and explain the present invention, but not to limit the technical solution of the present invention.

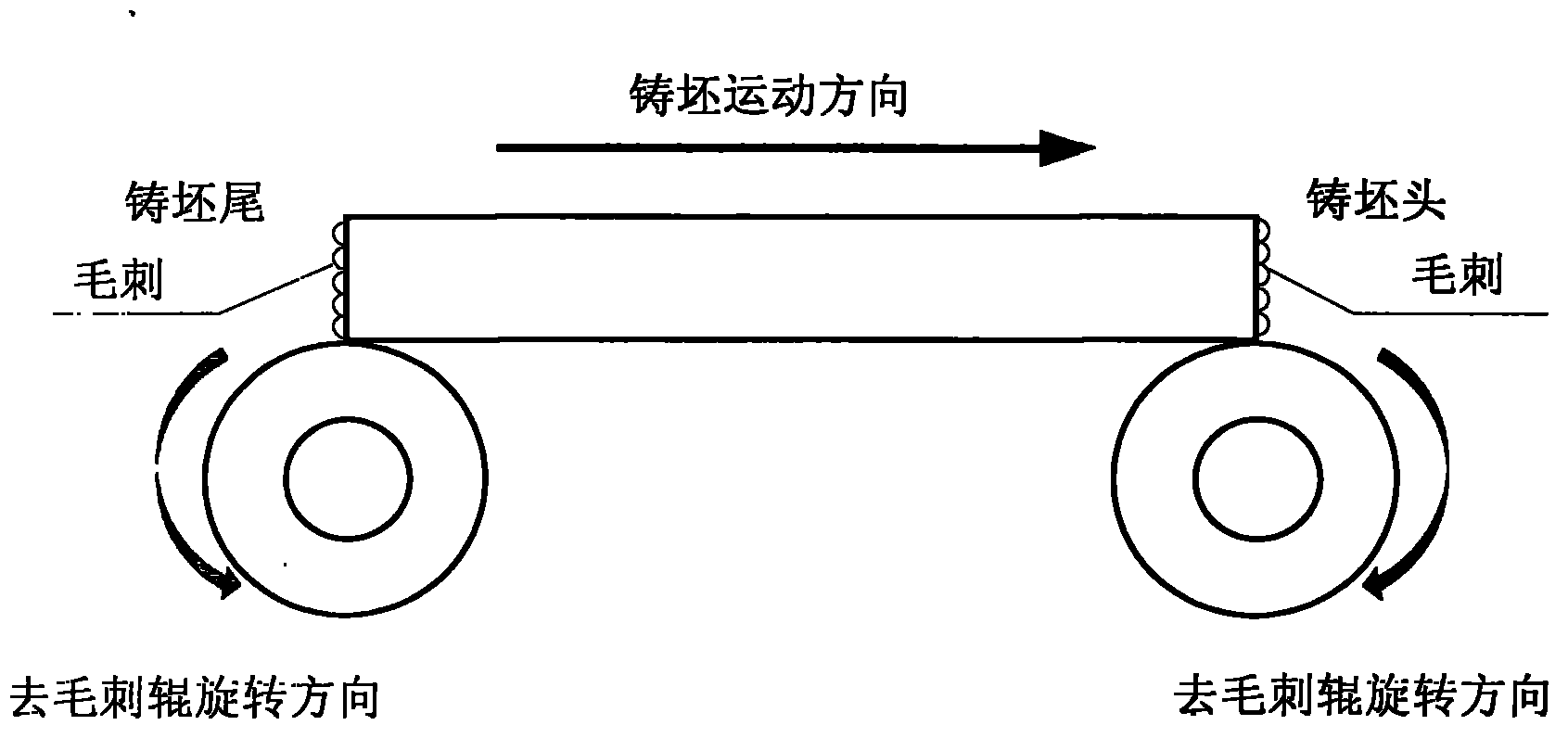

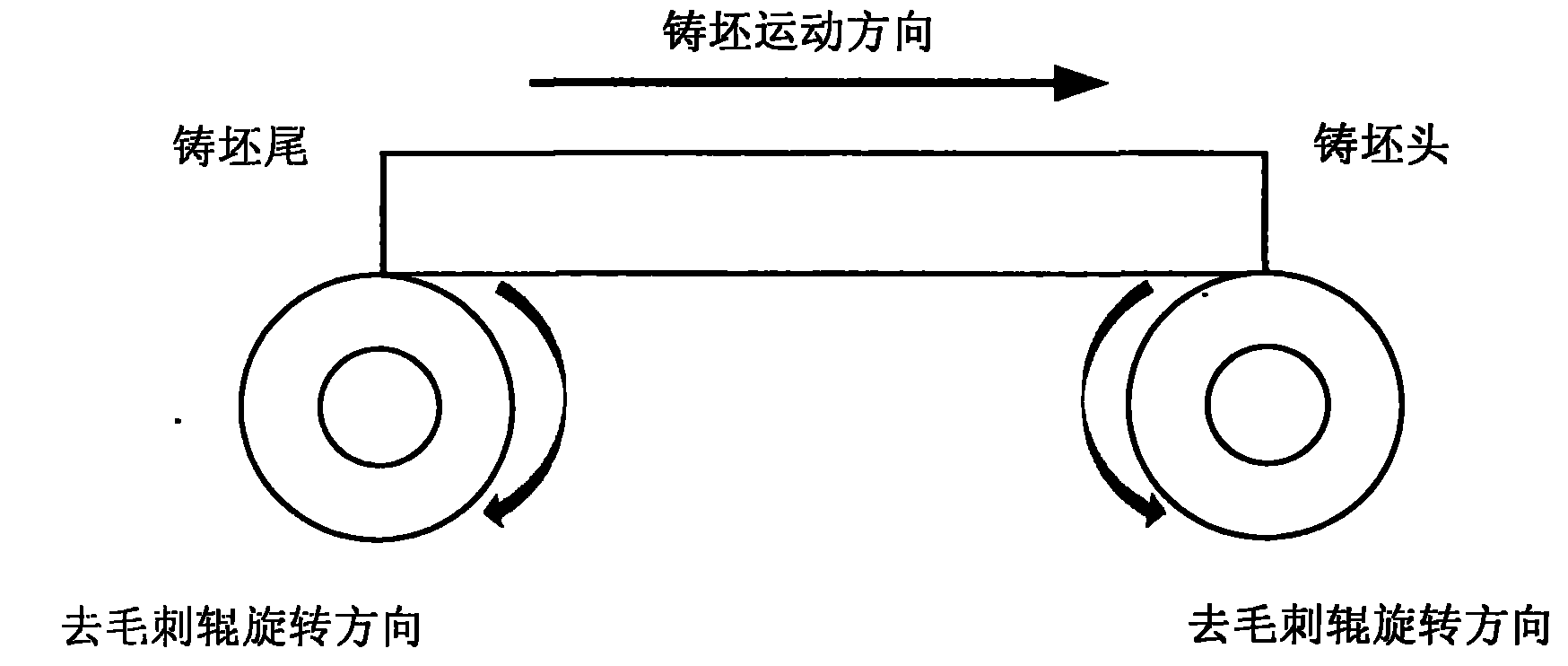

[0023] Please refer to figure 2 shown. The method for controlling the rotation of the slab deburring machine of the present invention includes:

[0024] In the step of removing the burrs under the head of the slab, the deburring roller located at the head of the slab rotates opposite to the moving direction of the slab; The burr rollers rotate against the direction of movement of the strand.

[0025] The foregoing method embodiments specifically include:

[0026] When the head of the slab passes through the deburring machine, the first start signal is sent by the detection device, so that the deburring machine corresponding to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com