Battery cast-weld bottom-die mold

A technology of casting welding and bottom mold, which is applied in the field of battery casting and welding bottom molds, can solve the problems of false welding, virtual welding, and low specific heat of lead alloy, and achieve the effect of solving virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

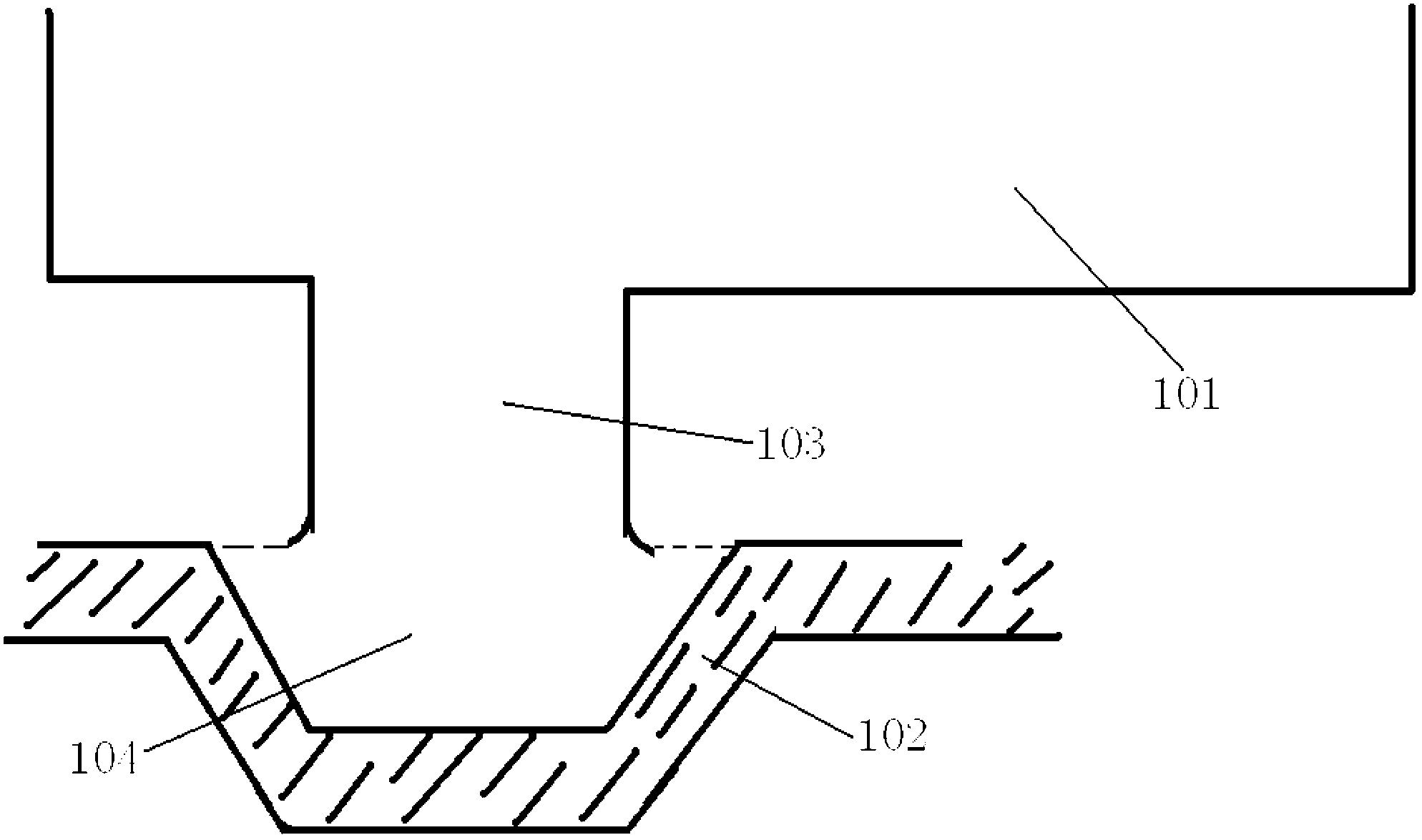

[0015] Please refer to figure 1 , battery casting and welding refers to putting the tab 103 of the battery plate 101 into the bus bar cavity 104 of the cast welding bottom mold 102, the bus bar cavity 104 is filled with high-temperature lead alloy, the high-temperature lead liquid and the tab lead The alloy melts for effective welding. However, since the negative tab of the battery is thinner than the positive tab, the heat required to melt the positive tab is more than the heat required to melt the negative tab, resulting in different casting and welding quality between the positive tab and the negative tab. According to the heat transfer formula Q=CM(T 2 -T 1 ), because the positive lug is thicker, more heat needs to be absorbed to melt the lug during casting and welding, so those skilled in the art thought of increasing the size of the positive busbar cavity in the casting and welding bottom mold, which is equivalent to improving the heat transfer The variable M in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com