Electrical-control vehicle-mounted capping mechanism device for hot metal ladle

An electronically controlled vehicle and iron-carrying technology, applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of low reliability, heat loss, large overall quality, etc., to improve safety and reliability, High environmental adaptability, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

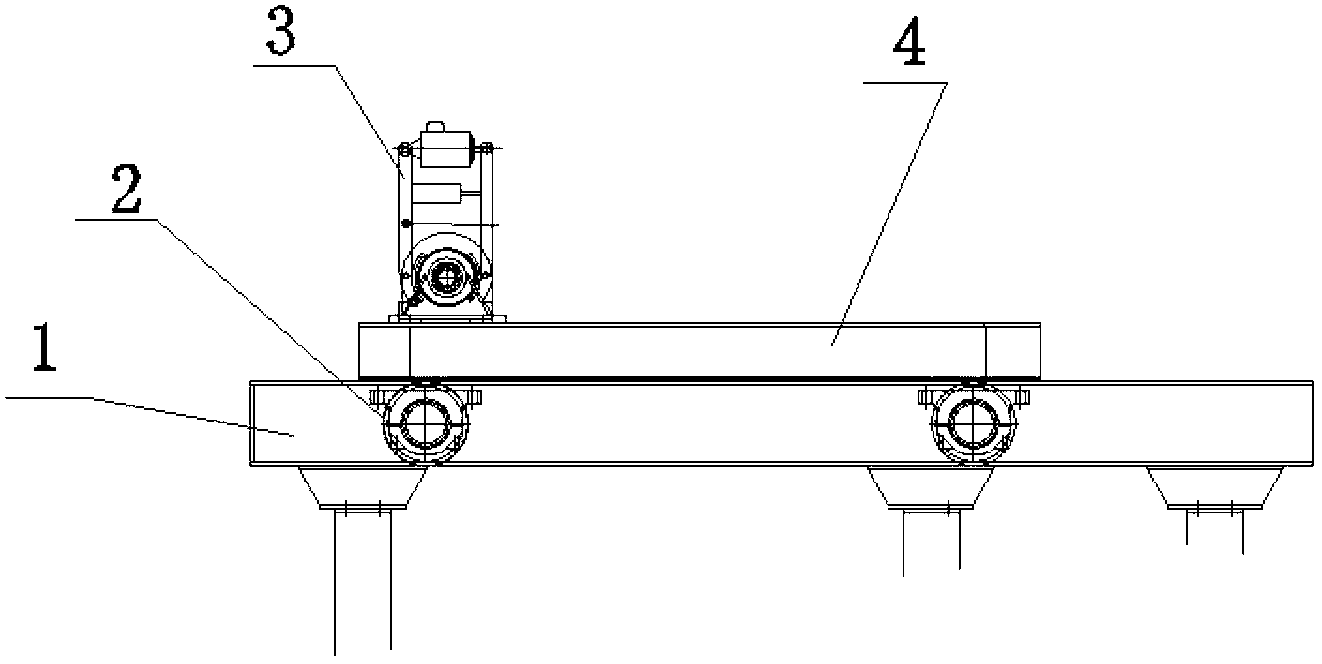

[0016] Such as figure 1 Shown is the schematic diagram of the trolley mechanism of the present invention. The driving motor 3 is installed on the frame 4. When the driving motor is working, its output shaft is driven by a pair of external gears, so that the active wheel set and the passive wheel set 2 run in the guide rail 1, thereby driving the whole trolley to move horizontally.

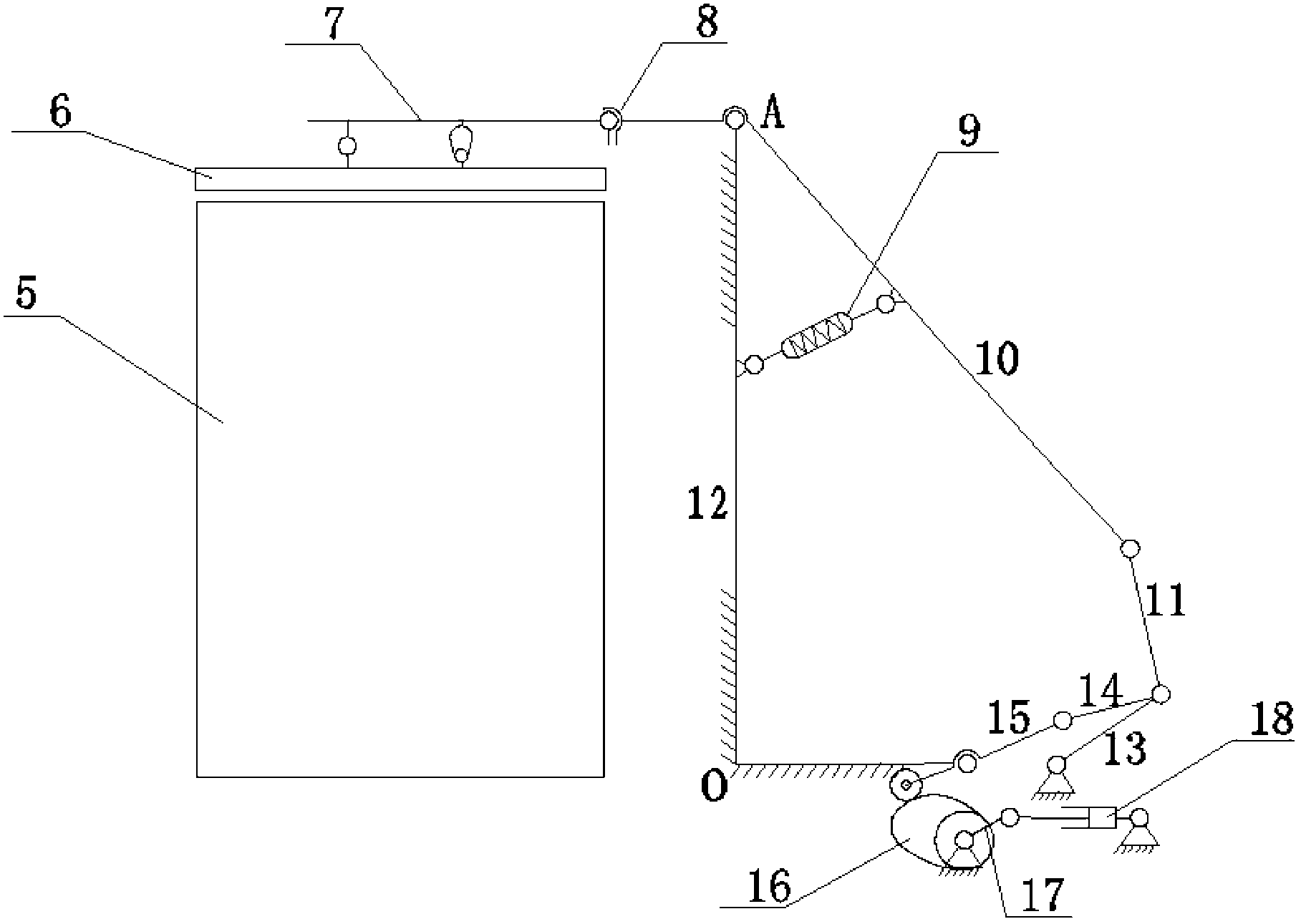

[0017] Such as figure 2 Shown is a schematic diagram of the electric rod mechanism assembly / opening process of the present invention. Electric push rod 18, crank 17 and drive cam 16 constitute a push rod-cam mechanism; connecting rod A13, connecting rod B14, connecting rod B15 and frame 12 constitute an inner ring double rocker four-bar mechanism; opening and closing rocker arm 10 , connecting rod A11, connecting rod A and the frame form an outer ring double rocker four-bar mechanism; the two ends of the auxiliary balance spring 9 are hinged on the opening and closing rocker arm 10 and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com