Device capable of effectively improving sand filling effect of steel ladle

A ladle and sand filling technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems that the upper nozzle of the ladle is not easy to fill, the water cannot be fully removed, and the ladle cannot be automatically poured, so as to improve the automatic opening. Casting rate, simple structure, save the effect of manpower operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

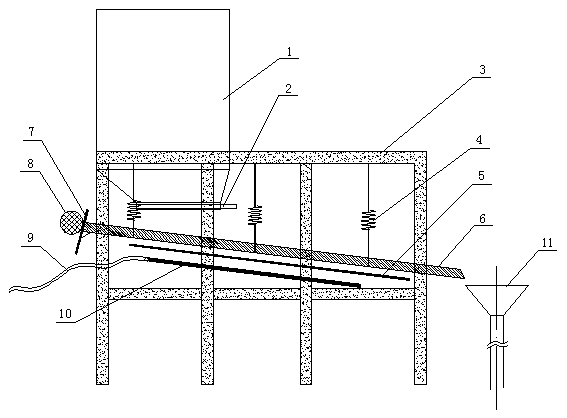

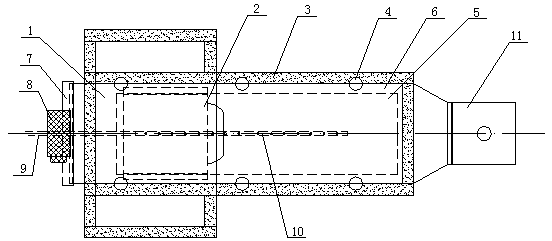

[0024] pass figure 1 , figure 2 It can be seen that the device for effectively improving the ladle sand filling effect of the present invention includes a bracket 3 on which the drainage sand bin 1 with a sliding bin door 2 at the bottom is fixed, and a vibrator fixing plate 7 is installed at the end to vibrate. The drainage sand guide groove 6 of the machine 8, the other end of the guide groove 6 is placed directly above the funnel-shaped conduit 11, and the guide groove 6 is hung on the support 3 in a flexible connection mode, and the guide groove 6 is placed on the guide groove 6. The sliding door 2 of the quicksand bin 1 is directly below; it also includes a heating plate 5 fixed on the support 3 and placed directly below the guide groove 6, and a porous gas steel pipe 10 fixed on the support 3 for heating the heating plate 5. The gas connection hose 9 is connected to the end of the porous gas steel pipe 10 described above. By installing a heating plate under the guide ...

Embodiment 2

[0031] pass figure 1 , figure 2 It can be seen that the device for effectively improving the ladle sand filling effect of the present invention includes a bracket 3 on which the drainage sand bin 1 with a sliding bin door 2 at the bottom is fixed, and a vibrator fixing plate 7 is installed at the end to vibrate. The drainage sand guide groove 6 of the machine 8, the other end of the guide groove 6 is placed directly above the funnel-shaped conduit 11, and the guide groove 6 is hung on the support 3 in a flexible connection mode, and the guide groove 6 is placed on the guide groove 6. The sliding door 2 of the quicksand bin 1 is directly below; it also includes a heating plate 5 fixed on the support 3 and placed directly below the guide groove 6, and a porous gas steel pipe 10 fixed on the support 3 for heating the heating plate 5. The gas connection hose 9 is connected to the end of the porous gas steel pipe 10 described above. By installing a heating plate under the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com