Anti-cracking electrode plate coating sintering process for dirt water treatment

A sewage treatment and electrode plate technology, which is applied in the direction of coating, surface pretreatment, and liquid coating device on the surface, etc., can solve the problems of weak bonding between the substrate of the electrode plate and the coating, and easy cracking of the coating. Achieve increased true geometric surface area, enhanced corrosion resistance, less porosity and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

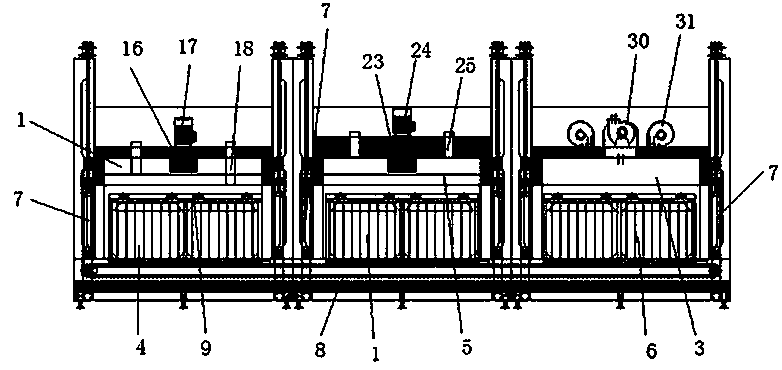

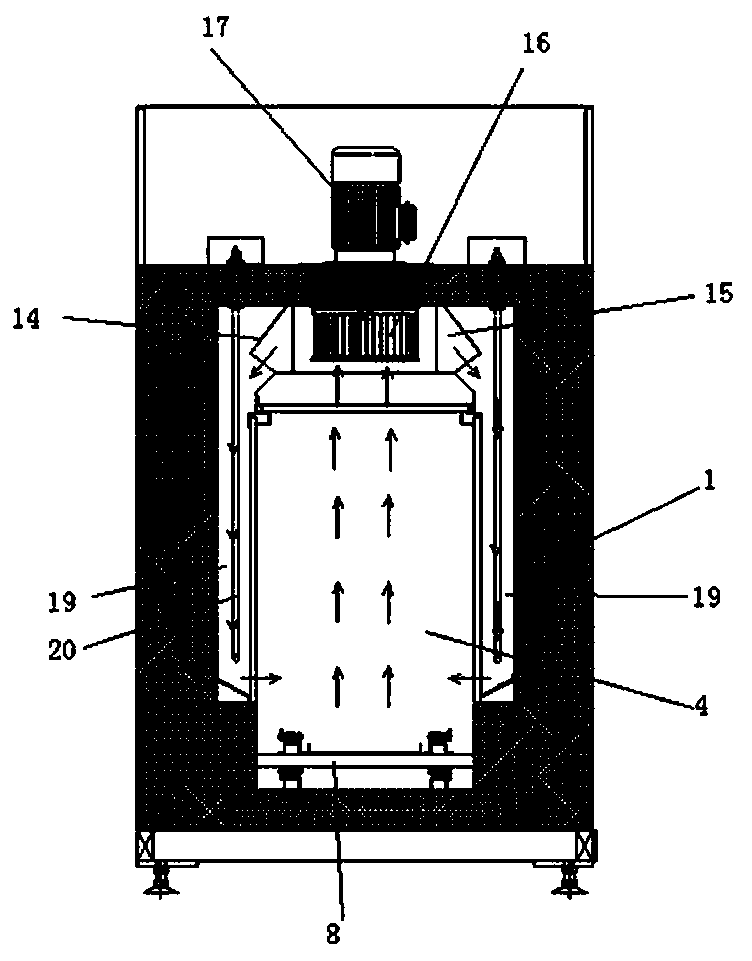

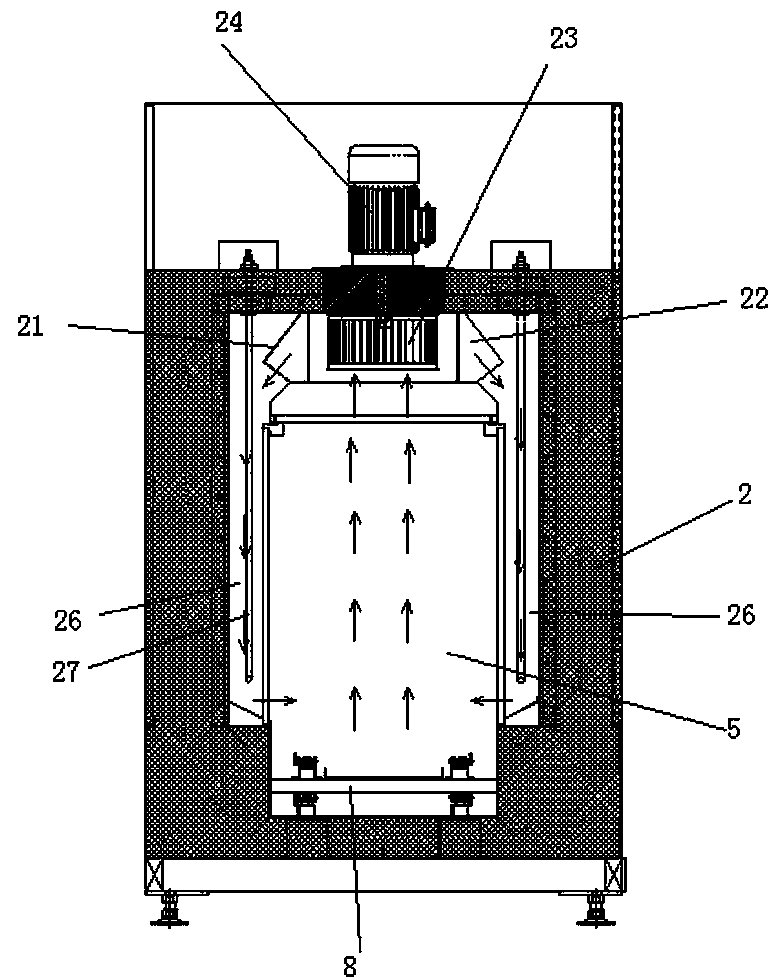

Image

Examples

Embodiment 1

[0028] Embodiment 1: The anti-cracking electrode plate coating sintering process for sewage treatment includes the following steps: the electrode plate coated with the coating enters the drying preheating section, the temperature of the drying preheating section is 150-200 ° C, and the drying The time for intervening in the hot section is 10-15 minutes; the electrode plate after drying and preheating will directly enter the high-temperature sintering section without contact with the outside. The temperature of the high-temperature sintering section is 400-550°C. 10-15min; the electrode plate after high-temperature sintering is directly put into the cooling and holding furnace to cool to 200-300°C without contacting the outside; after the electrode plate is cooled to 200-300°C, move the electrode plate to the external area for cooling to room temperature; repeat the above steps for more than two times with the electrode plate cooled to room temperature, and the time for the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com