Zinc pot roller preheating method for improving surface quality of hot-dip galvanized steel plate

A technology of hot-dip galvanized steel sheet and surface quality, applied in the field of metallurgy to achieve the effect of reducing defects, reducing heat loss and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

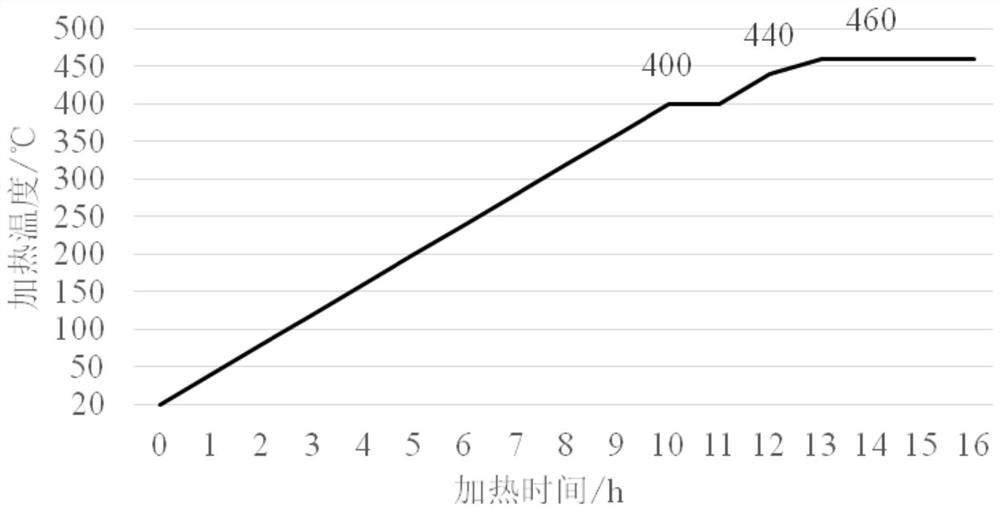

[0025] (1) The zinc pot roll is hoisted into the preheating box, heated to 400°C at a heating rate of 40°C / h, and kept for 1 hour after the temperature reaches 400°C;

[0026] (2) After holding for 1 hour, continue to heat the zinc pot roll from 400°C to 440°C at a heating rate of 40°C / h, and then heat the zinc pot roller from 440°C to 460°C at a heating rate of 20°C / h, and then Incubate at 460°C for 3h;

[0027] (3) The zinc pot rolls are loaded into the zinc pot within 1 hour before the production line starts, and the hoisting is completed within 0.5 hours. The production line starts within 0.5 hours after the hoisting is completed.

[0028] (4) Continuously anneal the acid-rolled steel strip, and then put it into a zinc pot for galvanizing treatment, and the temperature of the zinc liquid is 455°C; after the zinc pot is discharged, use a moving bellows to cool the galvanized steel strip to ≤155°C.

[0029] The surface quality of the prepared galvanized sheet is good, no si...

Embodiment 2

[0031] (1) The zinc pot roll is hoisted into the preheating box, heated to 400°C at a heating rate of 30°C / h, and kept for 1 hour after the temperature reaches 400°C;

[0032] (2) After holding for 1 hour, continue to heat the zinc pot roll from 400°C to 440°C at a heating rate of 30°C / h, and then heat the zinc pot roller from 440°C to 460°C at a heating rate of 20°C / h, and then Incubate at 460°C for 3h;

[0033] (3) The zinc pot rolls are loaded into the zinc pot within 1 hour before the production line starts, and the hoisting is completed within 0.5 hours. The production line starts within 0.5 hours after the hoisting is completed.

[0034] (4) Continuously anneal the acid-rolled steel strip, and then put it into a zinc pot for galvanizing treatment, and the temperature of the zinc liquid is 455°C; after the zinc pot is discharged, use a moving bellows to cool the galvanized steel strip to ≤155°C.

[0035] The surface quality of the prepared galvanized sheet is good, no si...

Embodiment 3

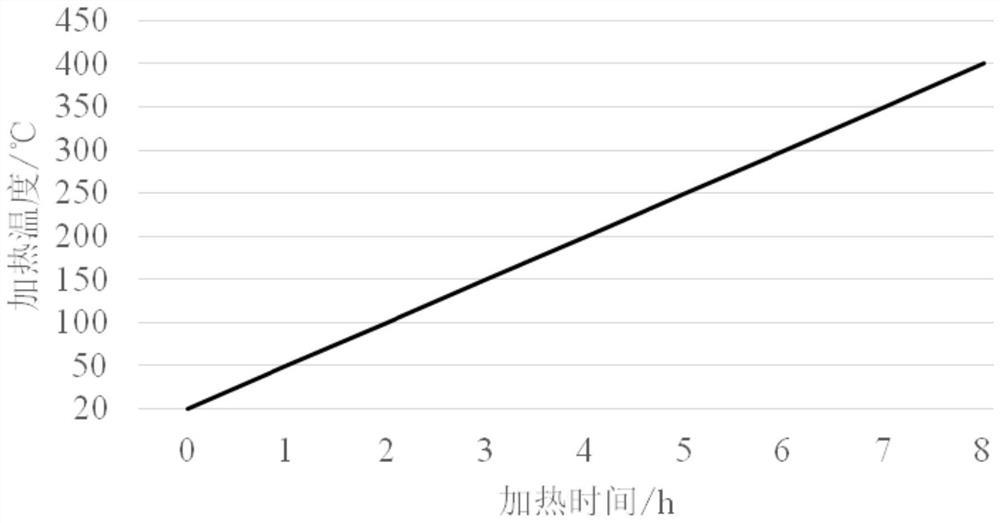

[0037] (1) The zinc pot roll is hoisted into the preheating box, heated to 400°C at a heating rate of 20°C / h, and kept for 1 hour after the temperature reaches 400°C;

[0038] (2) After holding for 1 hour, continue to heat the zinc pot roll from 400°C to 440°C at a heating rate of 20°C / h, and then heat the zinc pot roller from 440°C to 460°C at a heating rate of 30°C / h, and then Incubate at 460°C for 3h;

[0039] (3) The zinc pot rolls are loaded into the zinc pot within 1 hour before the production line starts, and the hoisting is completed within 0.5 hours. The production line starts within 0.5 hours after the hoisting is completed.

[0040] (4) Continuously anneal the acid-rolled steel strip, and then put it into a zinc pot for galvanizing treatment, and the temperature of the zinc liquid is 455°C; after the zinc pot is discharged, use a moving bellows to cool the galvanized steel strip to ≤155°C.

[0041] The surface quality of the prepared galvanized sheet is good, no si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com