Rapid docking mechanism for target stimulator bow cap and seeker

A target simulator and docking mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to the seeker, inability to achieve rapid installation, potential safety hazards, etc., to achieve accurate docking, convenient and fast docking, The effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

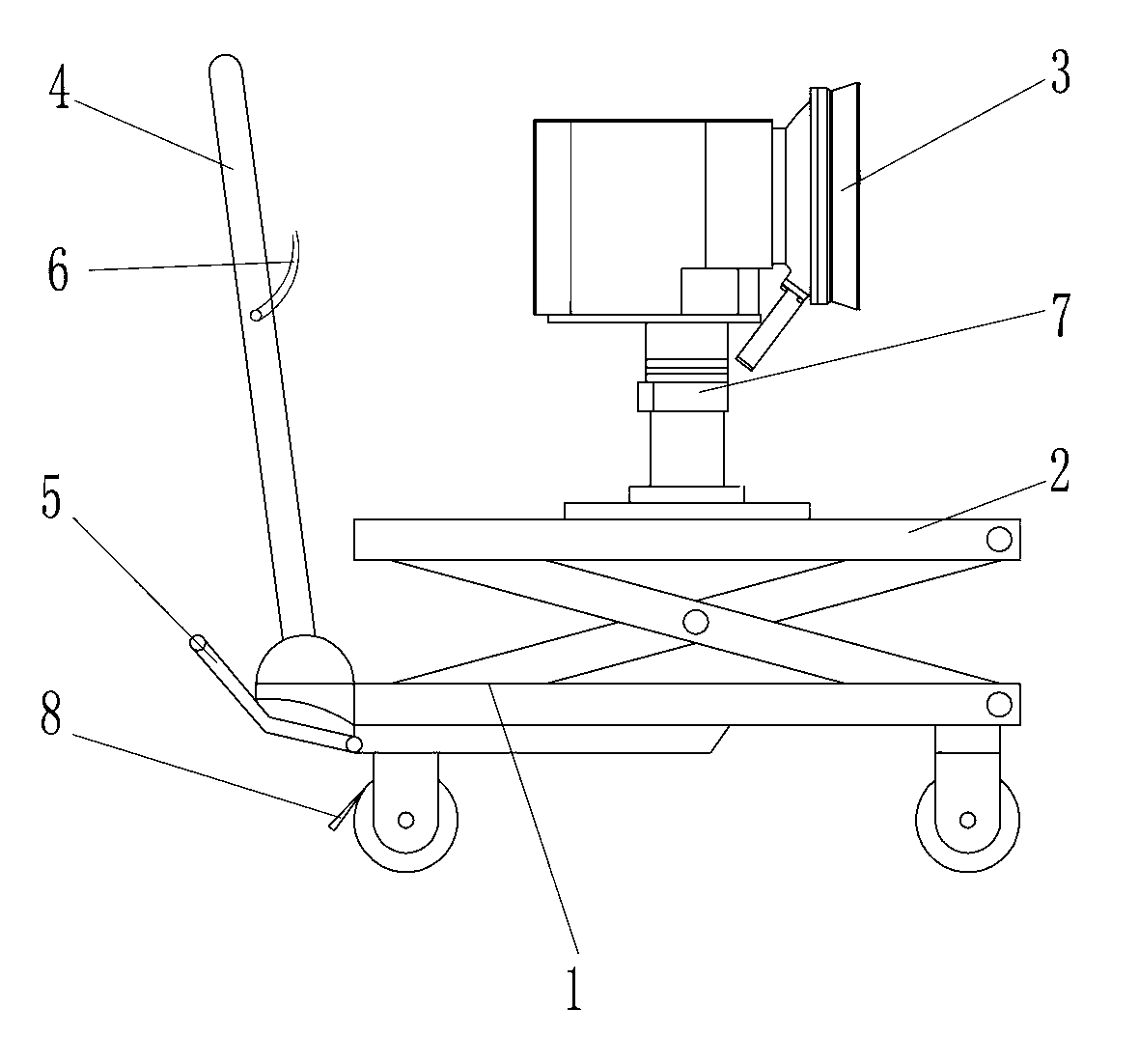

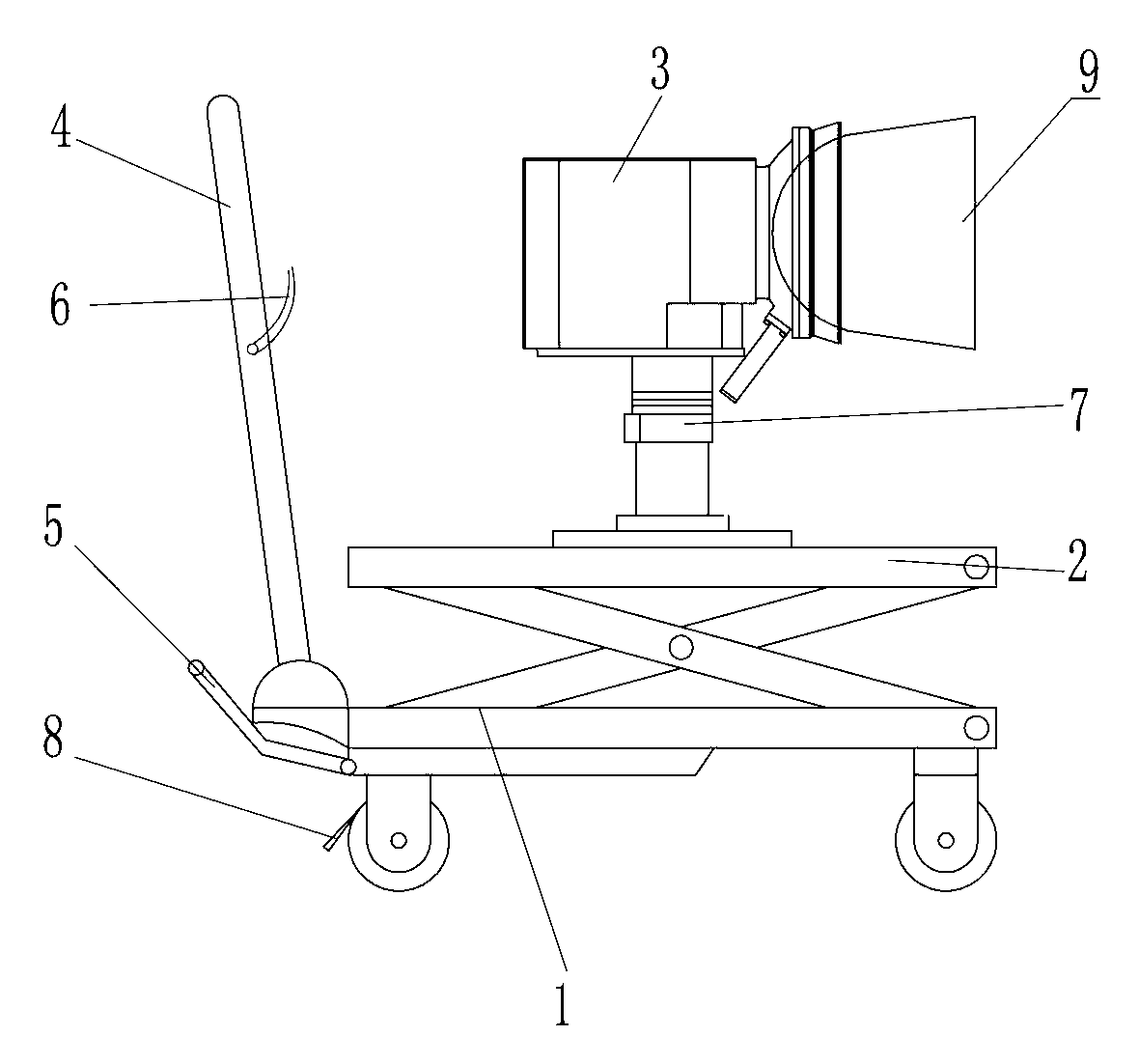

[0014] Example: see figure 1 , figure 2 .

[0015] A fast docking mechanism for a target simulator head cover and a seeker, including a lift car 1, the lift platform 2 of the lift car 1 is controlled by a hydraulic lift mechanism, and the target simulator head cover 3 is arranged on the lift of the hydraulic lift mechanism. On the platform 2, the lift car 1 is provided with a push rod 4.

[0016] The rise of the hydraulic lifting mechanism is controlled by the ascending pedal 5, and the descending is controlled by the descending hydraulic switch 6. The ascending pedal 5 and the descending hydraulic switch 6 control the hydraulic system to drive the hydraulic lifting mechanism to drive the lifting platform up and down, which is a common technology in the prior art The means are not described here.

[0017] The target simulator head cover 3 is firmly connected with the two-dimensional micro-adjustment device and adjusted by the two-dimensional micro-adjustment device 7 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com