Liquid purification device

A liquid purification device and liquid technology, applied in the field of liquid devices, can solve problems such as regular removal, and achieve the effect of suppressing accumulation in a container and saving removal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

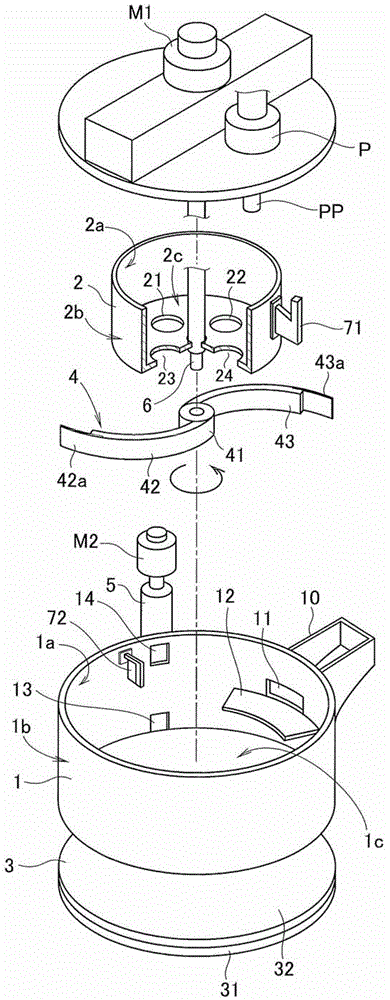

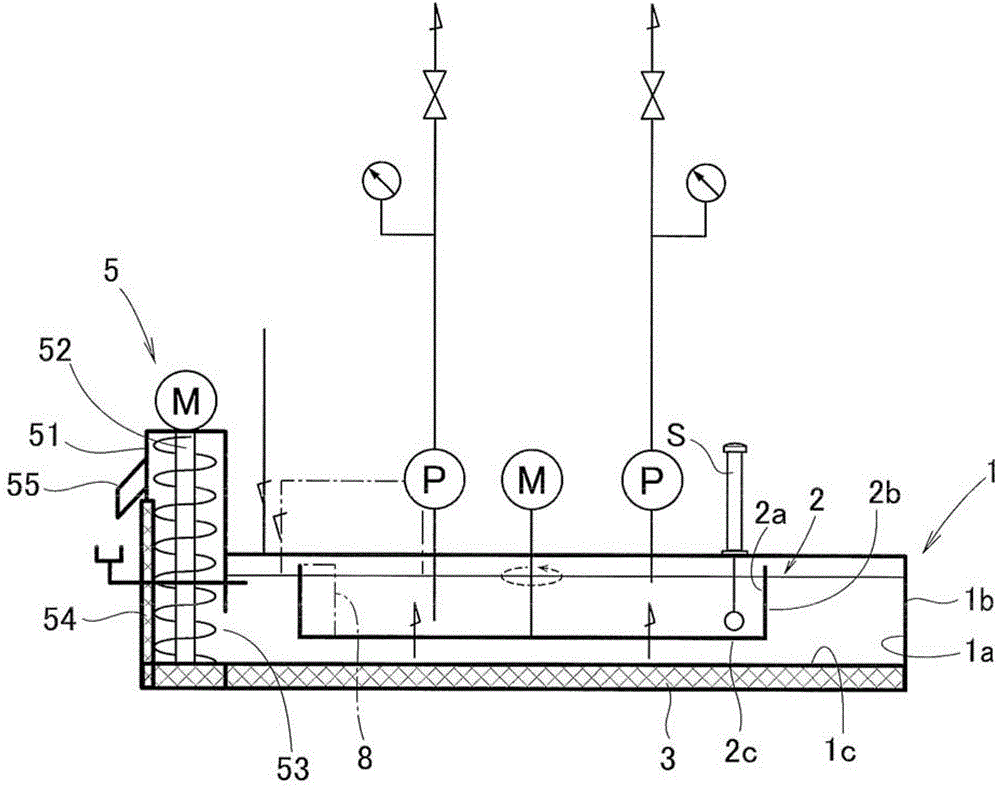

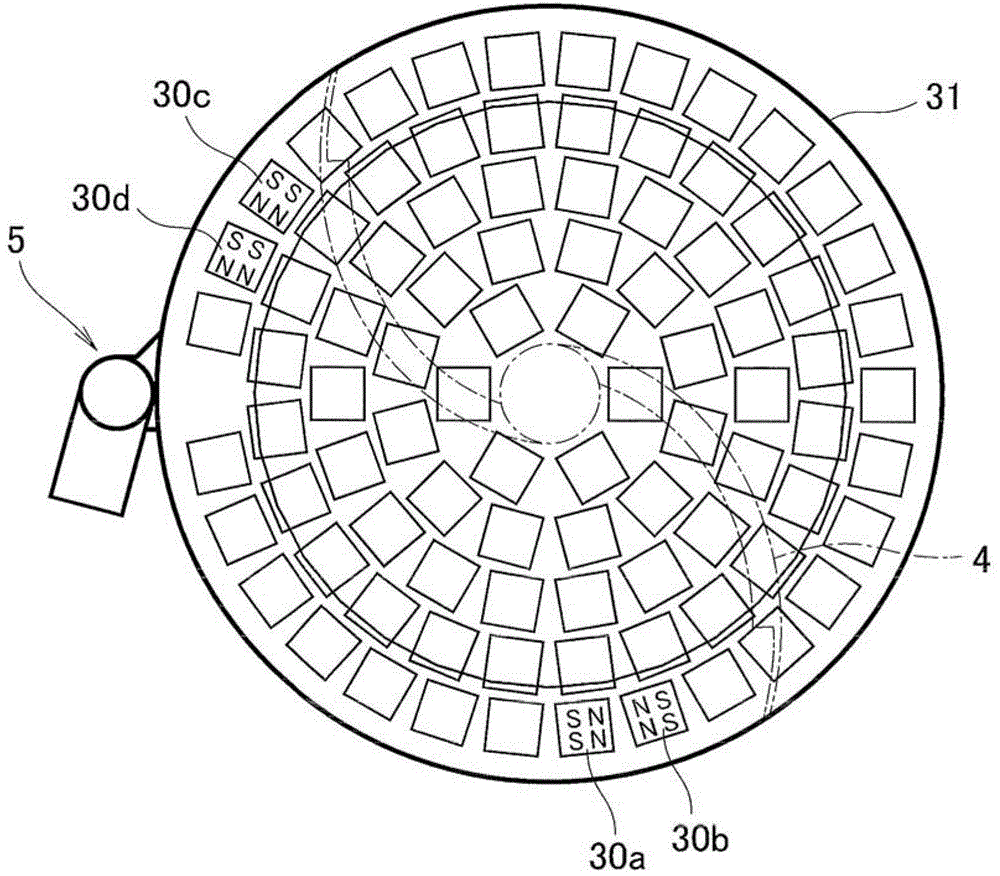

[0039] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a figure which shows the outline of embodiment of this invention. As shown in this figure, in this embodiment, a circular bottomed cylindrical second container 2 having a circular cross-sectional shape is arranged inside a bottomed cylindrical first container 1 having a circular cross-sectional shape. A magnetic field applying unit 3 is provided on the lower part of the bottom surface 1c of 1, and a scraper (guiding unit) 4 is provided on the lower part of the bottom surface 2c of the second container 2. In addition, a sludge recovery unit (recovery means) 5 is provided together outside the first container 1 .

[0040] The first container 1 is provided with an inflow portion 10 for receiving the inflow of turbid liquid, and an inflow port 11 for flowing into the inside of the container 1 from the inflow portion 10. In addition, on the inner surface 1a of the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com