Clamping mechanism

A technology of clamping mechanism and clamping part, which is applied in the direction of clamps, clamping, workpiece clamping devices, etc., can solve the problems of reducing work efficiency and complicated clamping operation, and achieves improved work efficiency, simple structure, and reduced labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

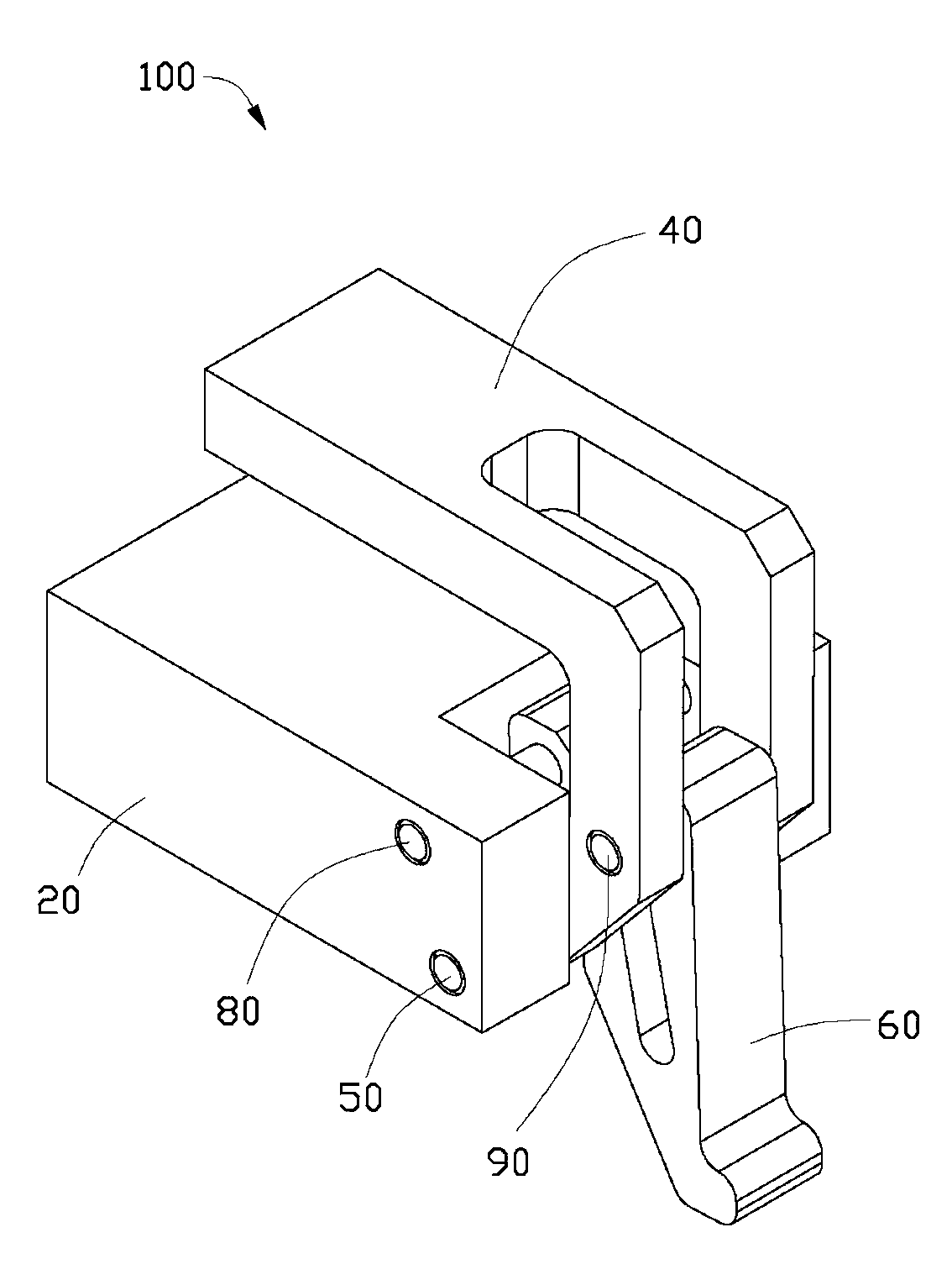

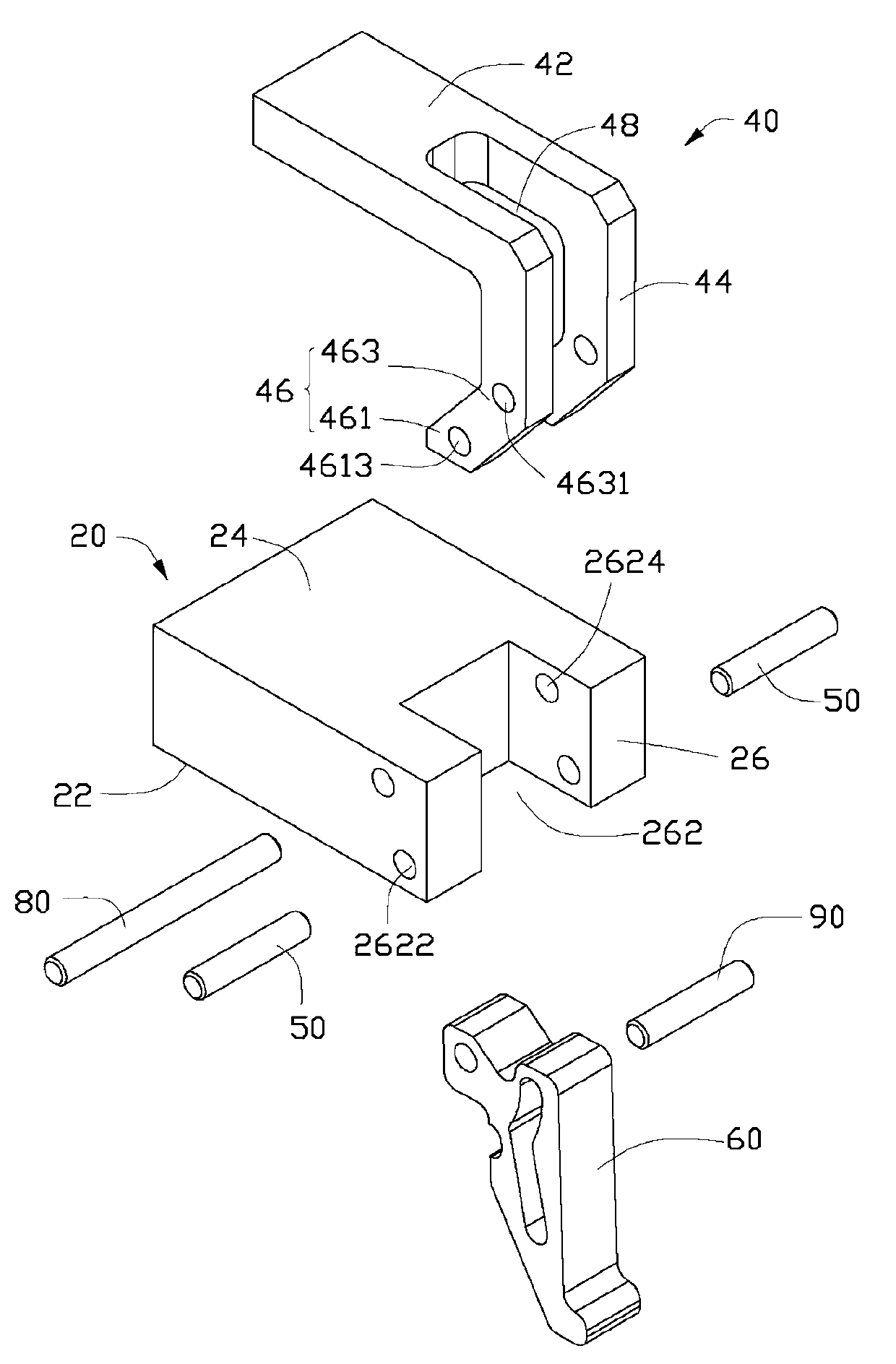

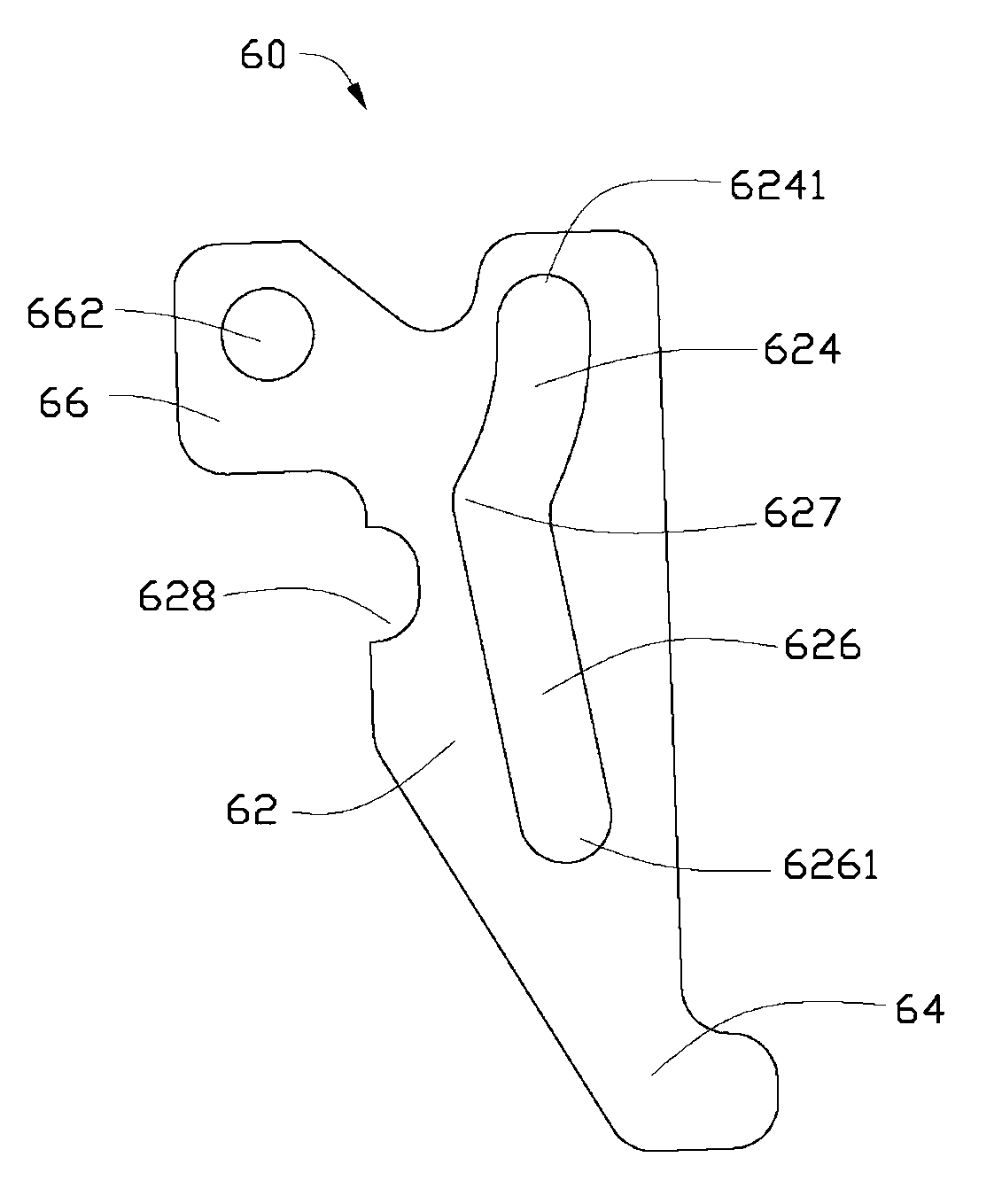

[0015] see figure 1 and figure 2 , the clamping mechanism 100 of this embodiment is used for workpiece 200 (such as Figure 4 shown) for quick loading and unloading, which includes a base 20 , a pressing block 40 , two pivots 50 , an eccentric handle 60 , a rotating shaft 80 and a guide 90 . The pressing block 40 is rotatably connected with the base 20 through two pivots 50 . The eccentric wheel handle 60 is relatively rotatably hinged with the base 20 through the rotating shaft 80, and is movably connected with the pressure block 40 through the guide 90, so as to control the rotation of the pressure block 40 around the base 20 to clamp or release the mounting on the base 20 Workpiece 200 on. In this embodiment, the pivot 50 , the rotating shaft 80 and the guide 90 are all rod-shaped pins.

[0016] The base 20 is roughly block-shaped, and includes a bottom surface 22 , a mounting top surface 24 and a side surface 26 opposite to the bottom surface 22 . It can be understoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com