Hydraulic chuck and slip assembling and disassembling device for drilling machines

A loading and unloading device, hydraulic technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems affecting the installation efficiency of slips in hydraulic chucks, increasing the production cost of enterprises, and bulky volume, etc., and achieves light weight, convenient operation, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

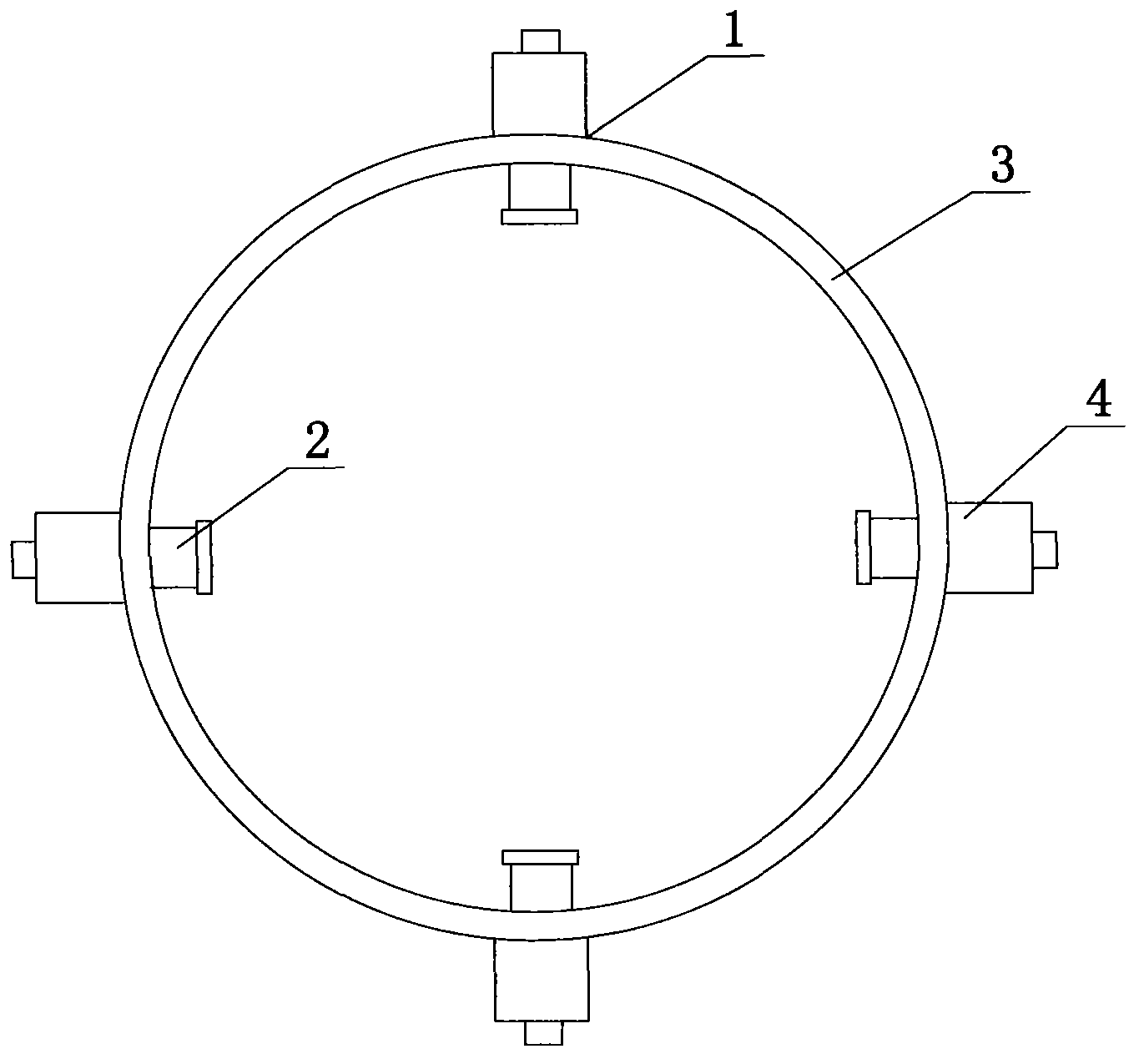

[0018] Such as figure 1 As shown, the hydraulic chuck slip loading and unloading device of the drilling rig in this embodiment is provided with a fixed collar 1 and a positioning pin 2 . The fixed ferrule 1 is provided with a cylindrical overcoat 3, and the periphery of the cylindrical overcoat 3 is welded and fixed with four positioning cylinders 4 at equal distances. The diameter of the cylindrical overcoat 3 is 2 times higher than the cylindrical overcoat 3. times, the diameter of the positioning cylinder 4 is a high 1 / 4th of the outer cover 3 of the cylinder.

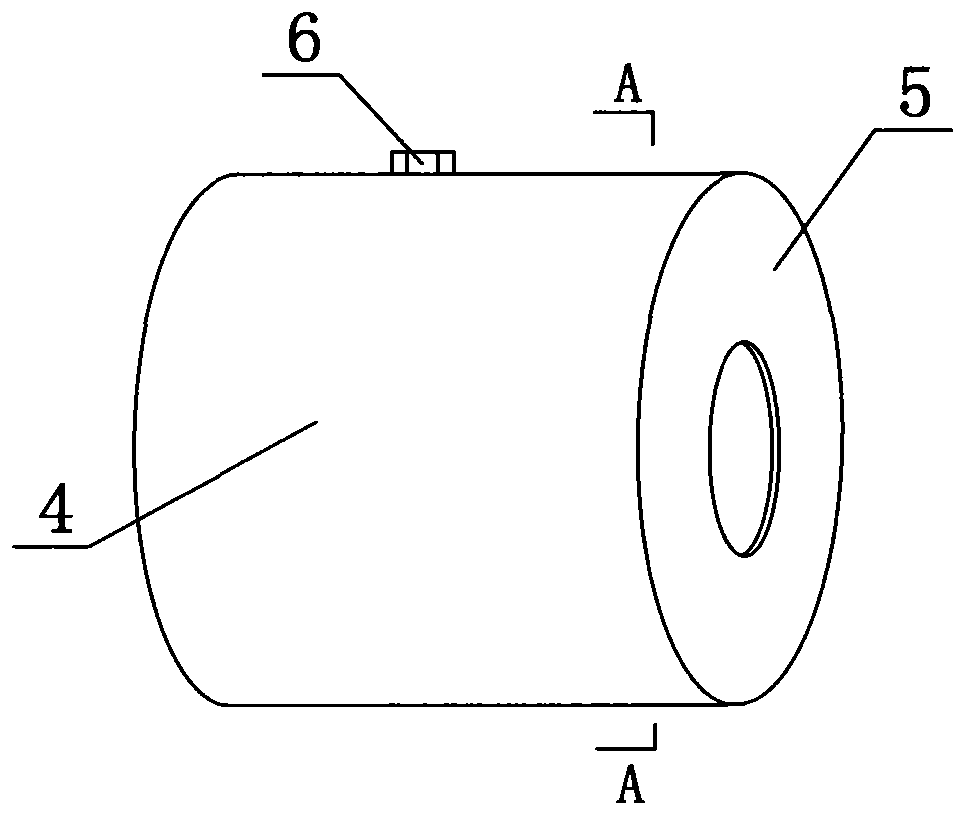

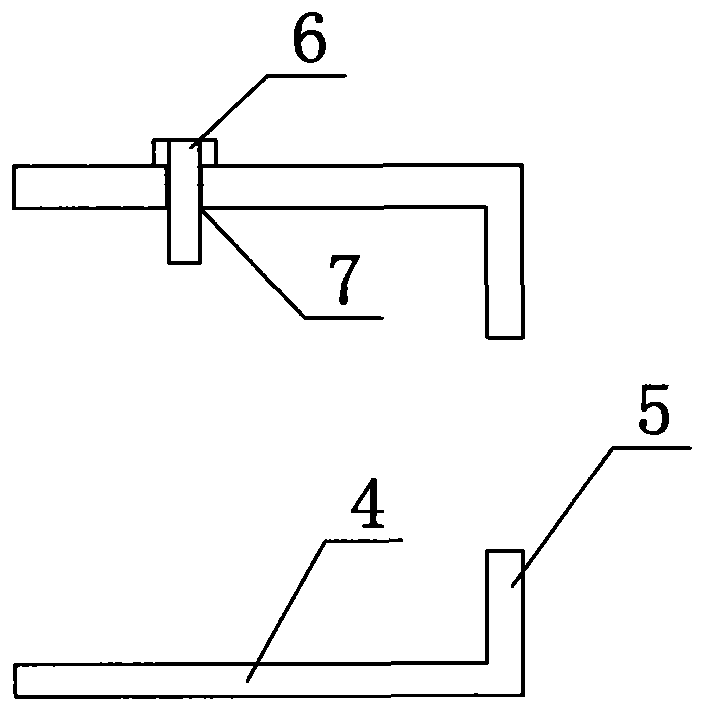

[0019] Such as figure 2 , image 3 As shown, the positioning cylinder 4 communicates with the outer casing 3 of the cylindrical body, the outer end of the positioning cylinder 4 is provided with a positioning ring 5, and the outside of the positioning cylinder 4 is provided with a limiting hole 7 through which the limiting bolt 6 passes. The set internal thread corresponds to the external thread of the limit bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com