Inner mould of tire vertical compression vulcanizing machine

A vulcanizing machine and inner mold technology, which is applied in the field of tire production equipment, can solve problems such as structural asymmetry, high cost of bladder use, and incomplete expansion of the bladder, so as to improve distribution, overcome incomplete expansion of the bladder, and improve uniformity and dynamics. The effect of balancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

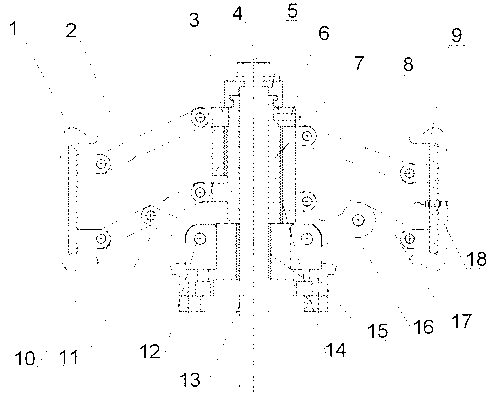

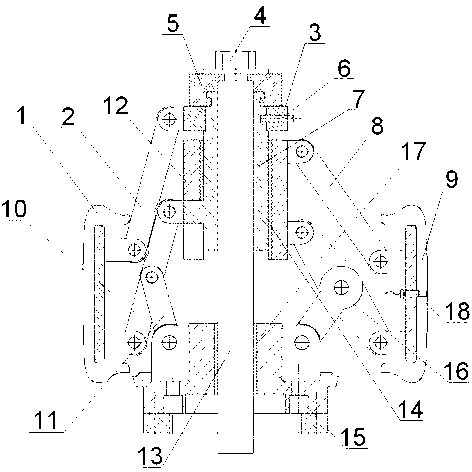

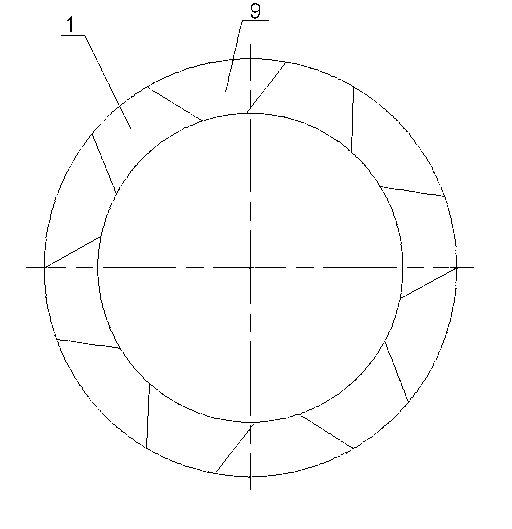

[0015] exist figure 1 , figure 2 , image 3 , Figure 4 Among them, the present invention includes an expansion and contraction mechanism and a transmission mechanism, wherein the expansion and contraction mechanism is mainly composed of a narrow tile expansion and contraction mechanism and a wide tile expansion and contraction mechanism, and the narrow tile expansion and contraction mechanism includes a narrow drum tile 1, a narrow tile upper connecting rod 2, Narrow tile lower link 10, narrow tile short link 11; wide tile expansion and contraction mechanism includes wide drum tile 9, wide tile upper link 8, wide tile lower link 17, wide tile short link 16; transmission mechanism includes base 15. Inner shaft sleeve 7, outer shaft sleeve 12, shaft end support ring 3. The narrow drum tile 1 is respectively connected with one end of the narrow tile upper connecting rod 2 and the narrow tile lower connecting rod 10 through the hinge support, the other end of the narrow tile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com