Self-control heating device for railway insulating tanker

A technology for tank cars and railways, which is applied to the field of self-controlled heating devices of railway thermal insulation tank cars, can solve the problems that the heating method and thermal insulation performance cannot meet the requirements for the shipment of chemical raw materials, are not suitable for the shipment of fine chemical raw materials, and have low transportation efficiency, and can avoid problems such as The local temperature is too high, the unloading operation time is saved, and the heating efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

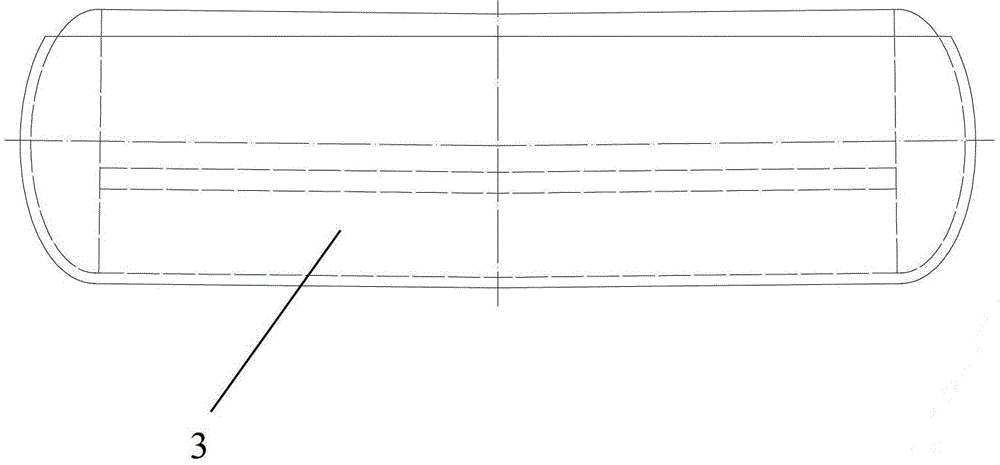

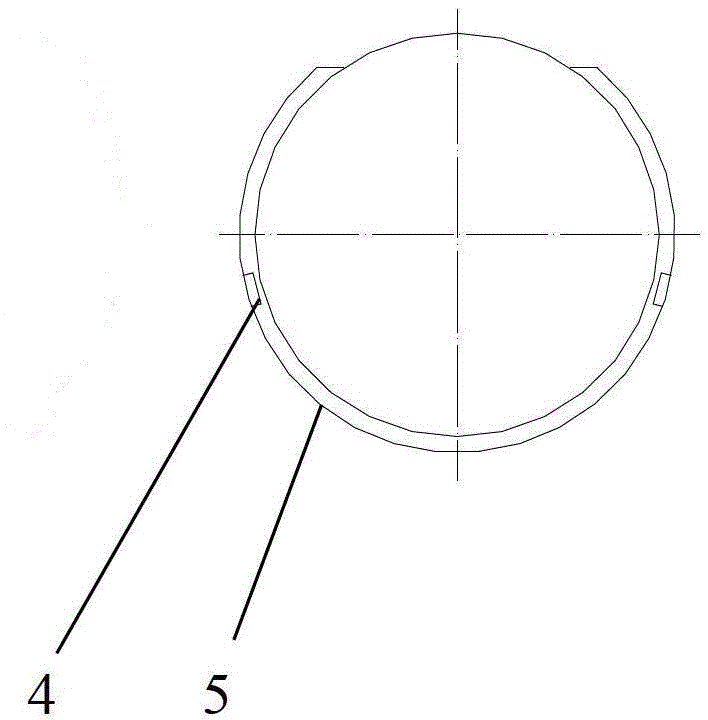

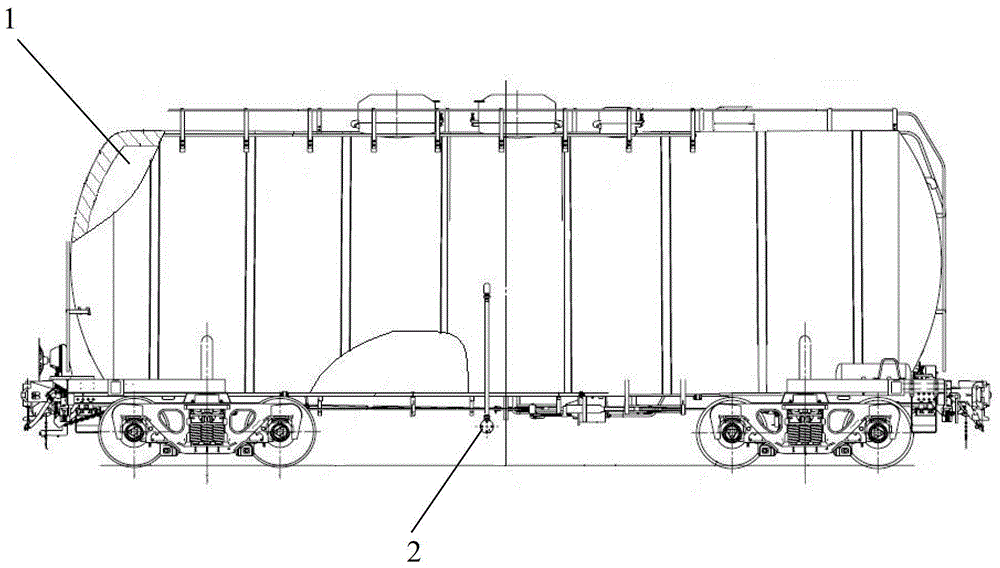

[0014] see Figure 1 to Figure 5 , the present invention includes a steam heating jacket 3 and a steam heating control system 2, the steam heating jacket 3 is arranged on the outer surface of the tank body 1 of the railway insulation tank car, and includes a steam heating cover 5 and a steam distribution groove 4, and the steam distribution groove 4 is a groove Type upper and lower opening structure (such as Figure 5 shown), arranged along the longitudinal length of the tank body 1, welded to the inner wall of the steam heating cover 5, without direct contact with the tank body, and the steam heating control system 2 has a steam pipe leading to the steam distribution tank 4.

[0015] The heating area of the steam heating jacket 3 reaches 70%-80% of the outer surface area of the tank body 1 .

[0016] The steam heating control system 2 includes a steam pipe on which a stop valve 6, a filter 7 and a self-acting temperature control valve 8 are installed. The self-acting tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com