Novel oxygenerator with gas-water separation structure and oxygen concentration monitoring function

A technology of separation structure and oxygen generator, which is applied in the direction of oxygen production, etc., can solve the problems of molecular sieve failure, failure to consider molecular sieve life, performance hazards, and decrease in adsorption capacity, so as to improve the life of oxygen production, improve the effect of oxygen production, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

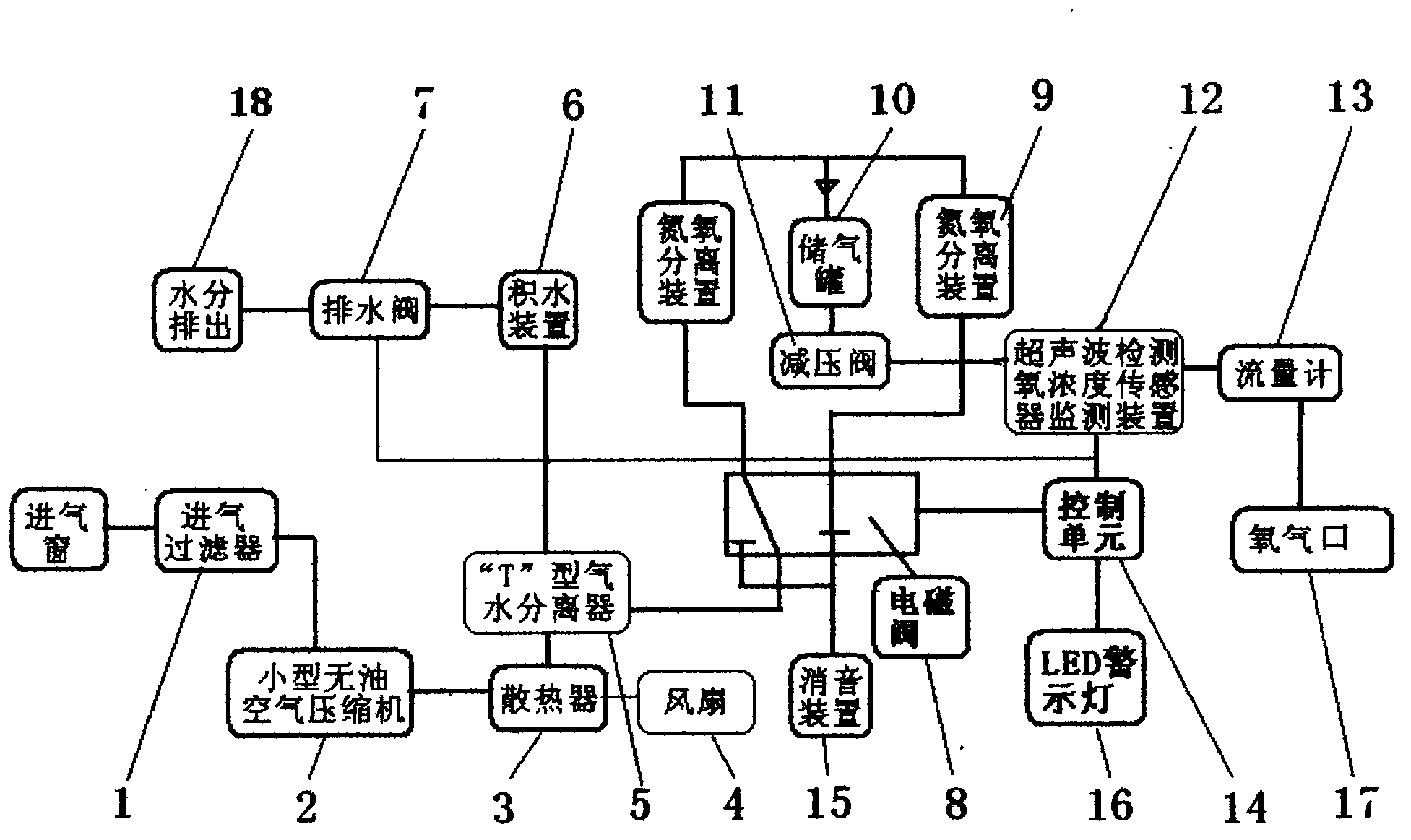

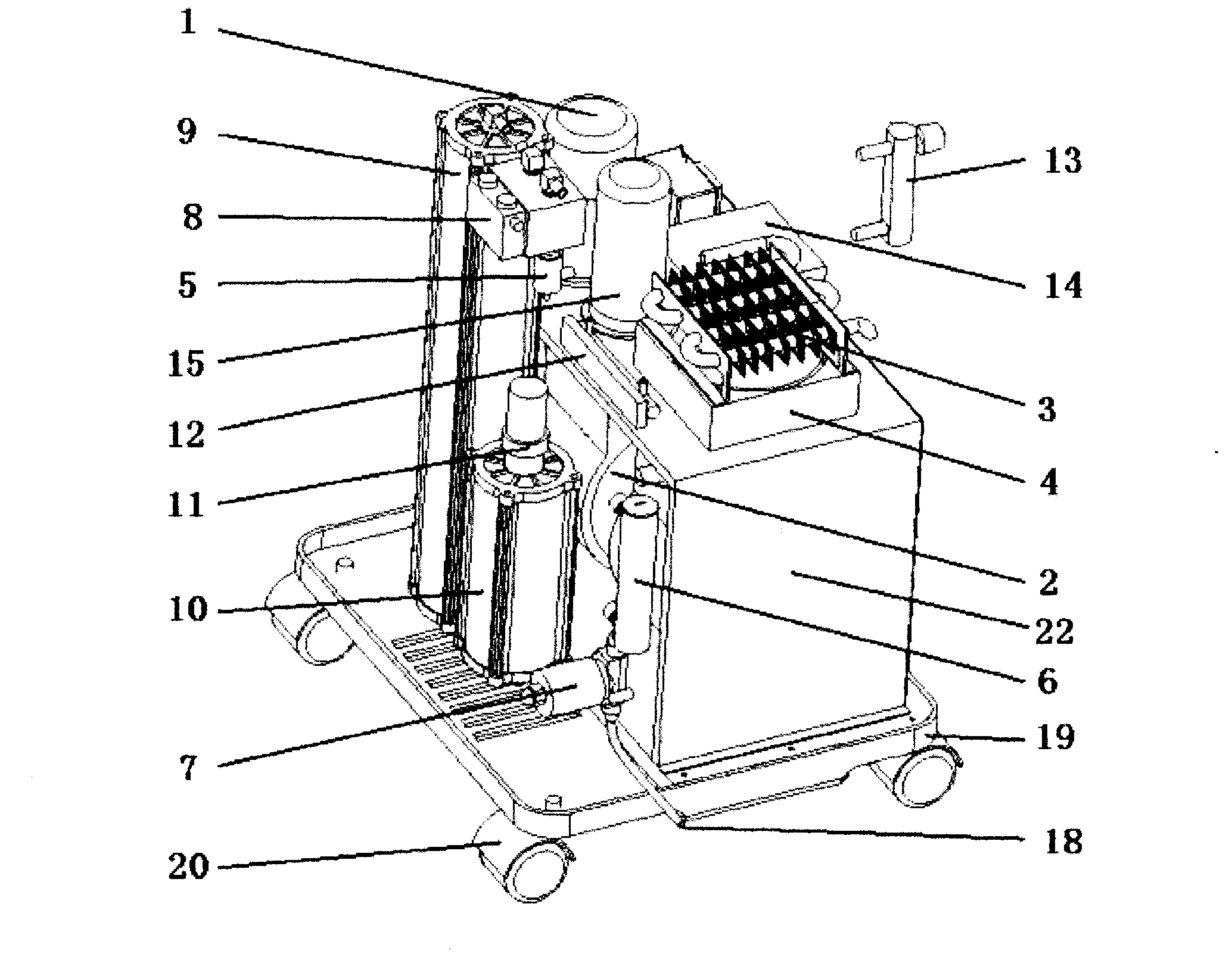

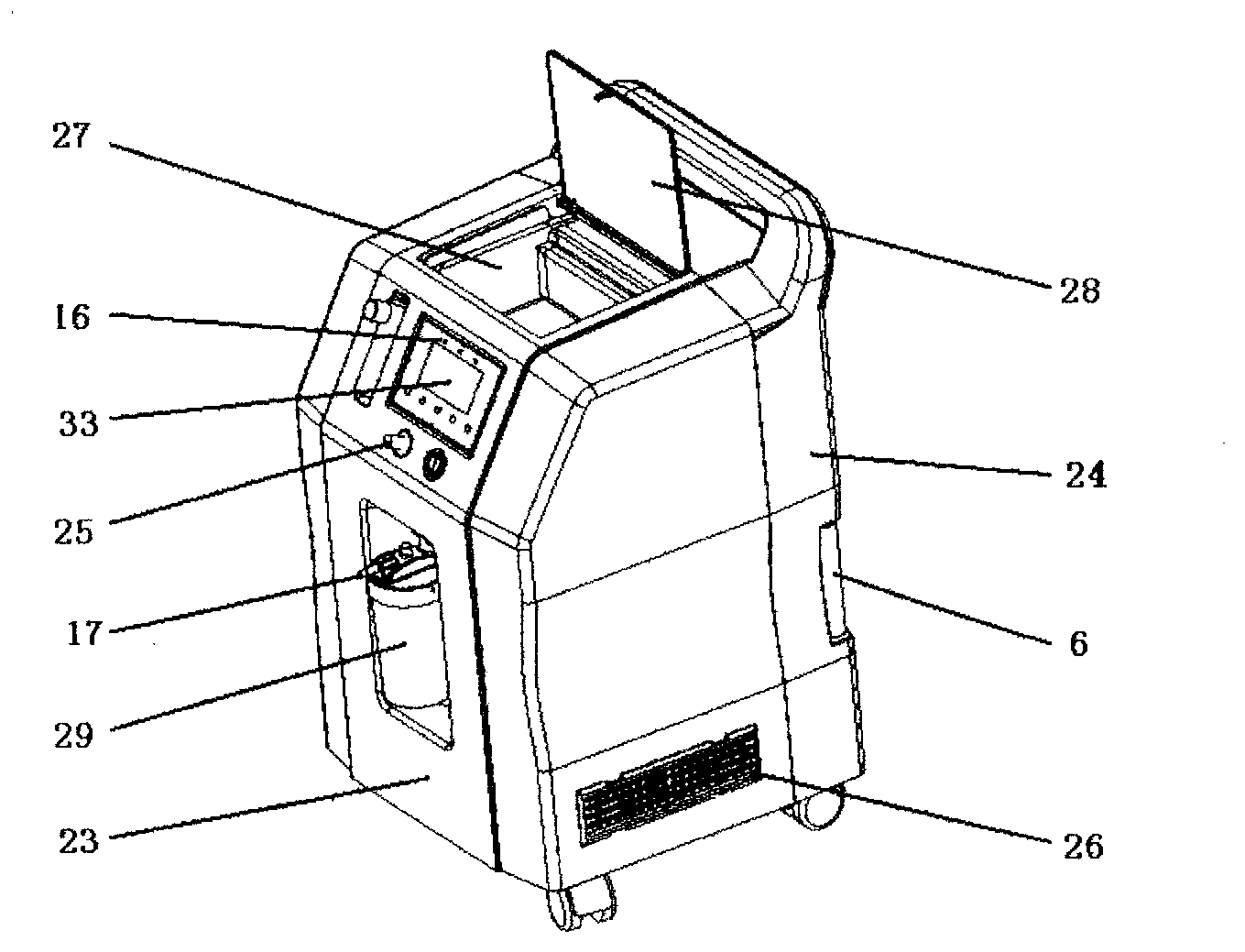

[0034] refer to Figure 1-8 , the specific embodiment adopts the following technical solutions: a new type of oxygen concentrator with gas-water separation structure and oxygen concentration monitoring, including an outer shell assembly and an inner shell assembly, and the outer shell assembly includes a base 19, an outer shell front cover 23 and an outer shell The rear cover 24, the upper part of the front side of the shell front cover 23 are provided with an LED warning light 16 and the atomization port 25, and the lower part of the front side of the shell front cover 23 is provided with an oxygen outlet 17 and a humidification bottle 29, and the humidification bottle 29 is also connected to the flow meter. 13 are connected, the housing front co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com