Sea water desalination spraying and liquid distributing sprayer

A nozzle and liquid distribution technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems of increasing seawater desalination costs, reducing the service life of heat transfer tube walls, and reducing the amount of liquid replenishment. The effect of desalination cost, improving seawater desalination efficiency, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

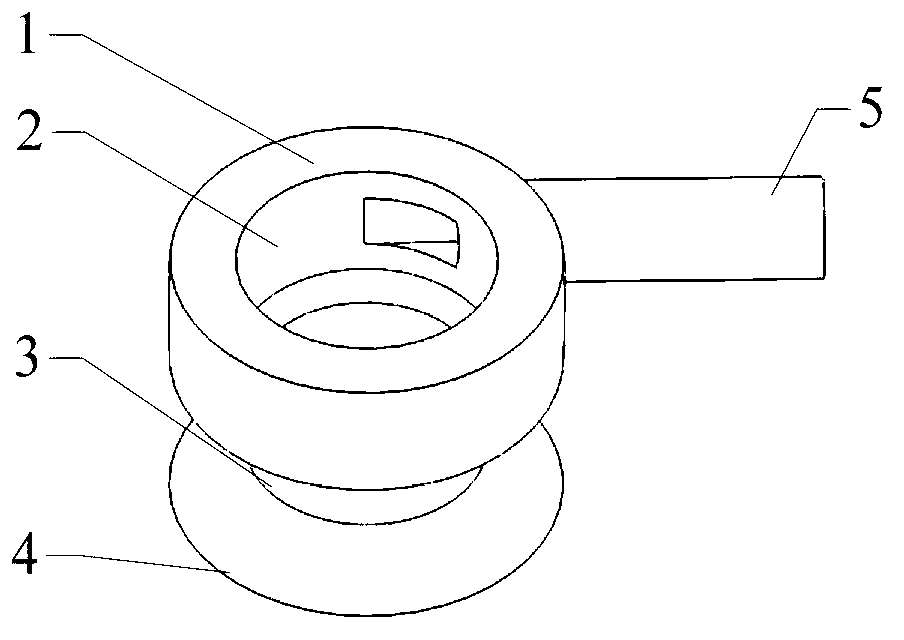

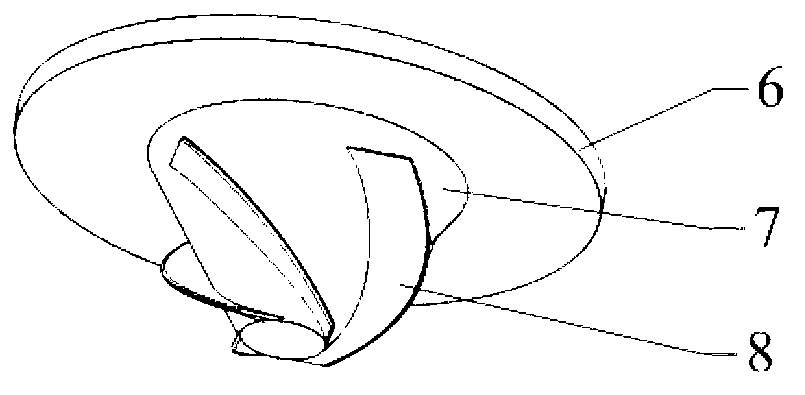

[0018] see figure 1 with figure 2 As shown, a spray nozzle for seawater desalination spray cloth according to the present invention includes a nozzle seat and a nozzle cover.

[0019] figure 1 It is the structural diagram of the nozzle seat, which is mainly used to connect the nozzle to the water supply pipeline. Such as figure 1 As shown, the nozzle seat includes an upper base 1 , a throat 3 and a lower nozzle 4 . A swirl chamber 2 is provided inside the upper base 1, and a water inlet 5 is connected tangentially to the side of the upper base 1, so that the seawater entering the nozzle forms a swirling flow. The bottom center of the upper base 1 is connected to the lower spout 4 through the throat 3 . The upper base 1 is used to connect the nozzle cover, the nozzle 4 is in the shape of an expanded trumpet, and the diameters of the swirl chamber 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com