Super soft siro spinning device

A siro spinning, ultra-soft technology, applied in the field of spinning, can solve the problems of low strength, increased end breakage, low twist, etc., and achieve the effect of easy installation, high cost performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

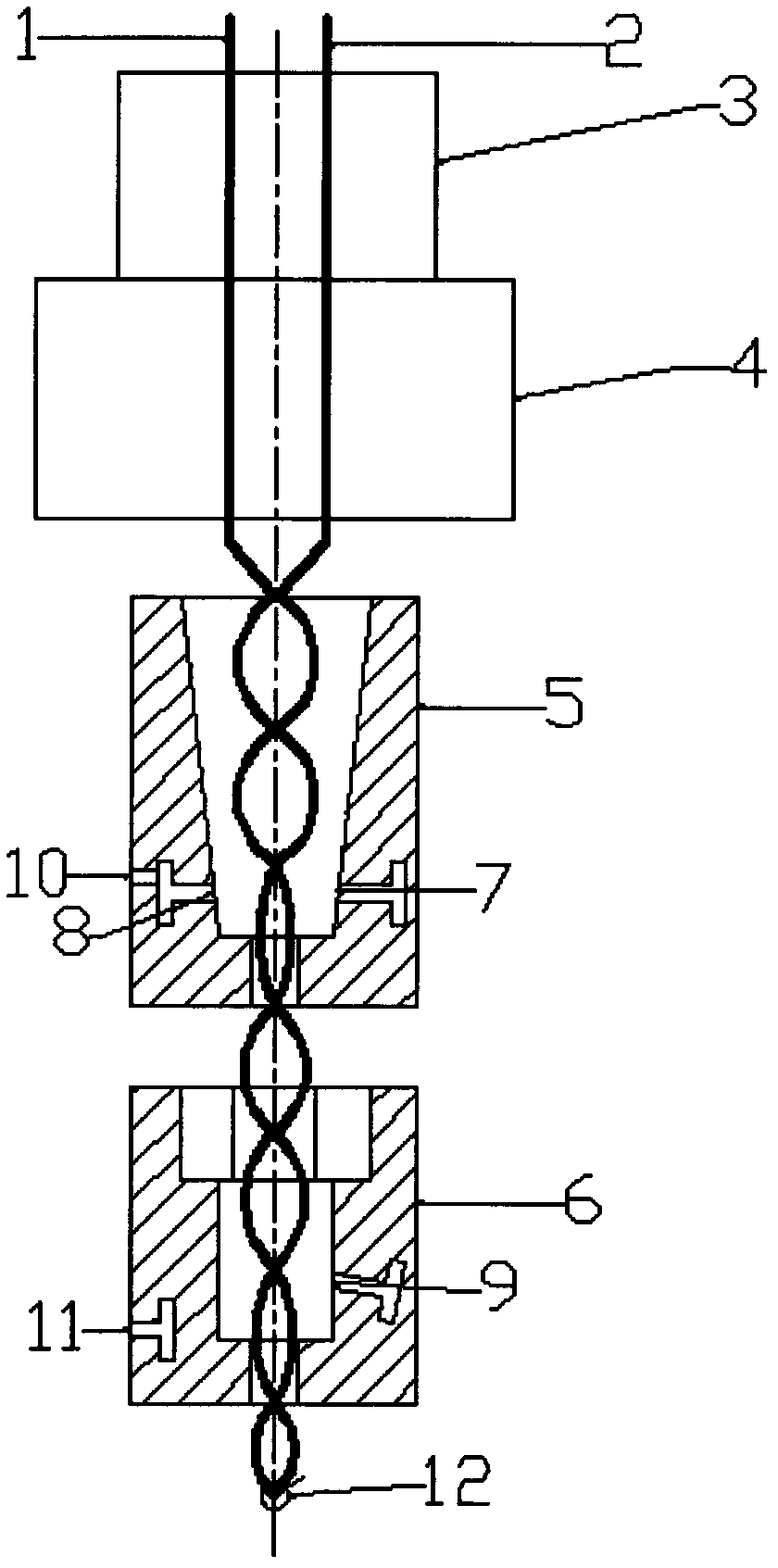

[0008] Depend on figure 1 As shown, after the two strands (1) and (2) in the separated state are gripped and outputted from the front roller (4) and the front rubber roller (3), they pass through the first nozzle (5), and the air flow passes through the air delivery port (10 ) to the air jet holes (7) and (8) to enter the yarn path for false twisting, and then pass through the second nozzle (6). Road, carry out false twist again, finally enter steel traveler (12) and be involved on the bobbin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com