Height sensing control system of bituminous pavement maintenance heater

A kind of asphalt pavement, height sensing technology, applied in the direction of road, road, road repair, etc., can solve the problem of trip switch reporting failure, affecting the normal operation of the road heater, vulnerable to impact and drag, etc., to improve safety, structure Simple and reasonable, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

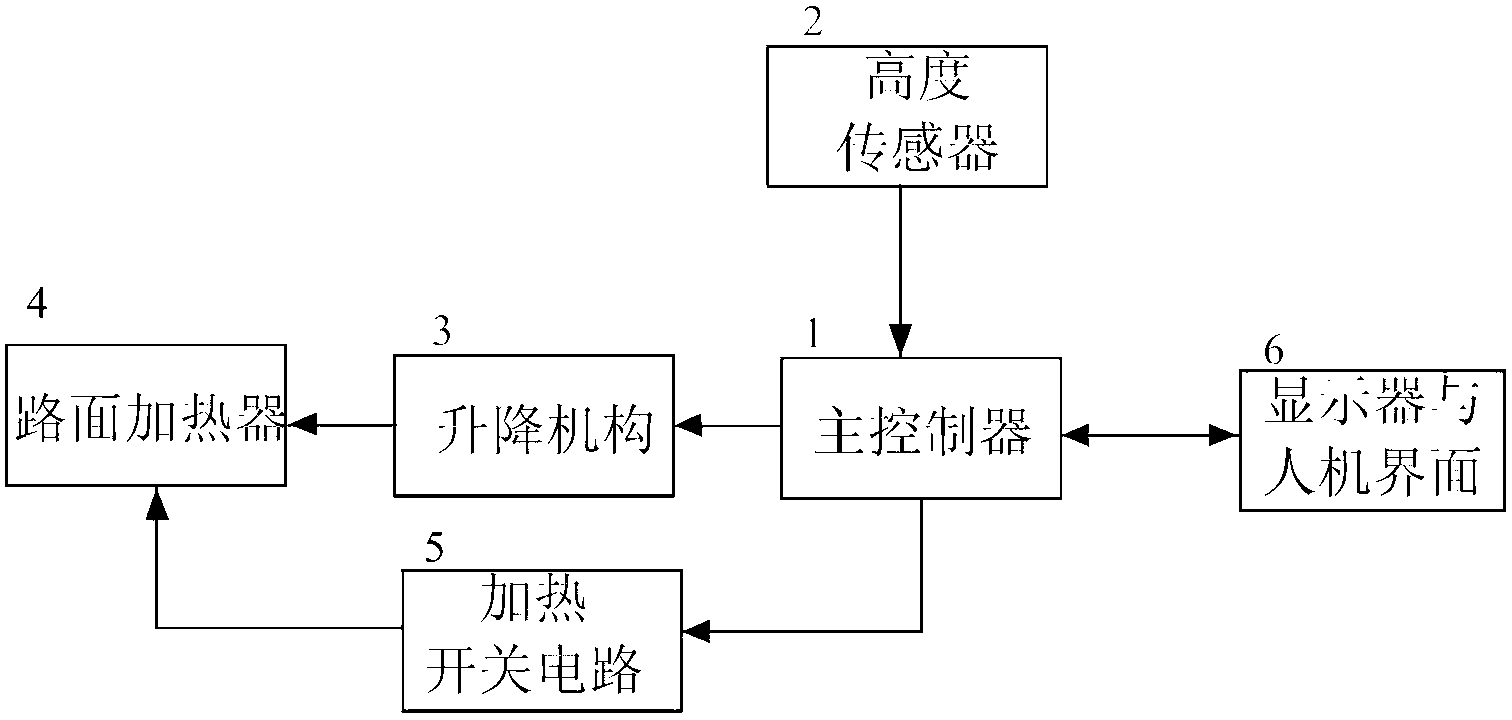

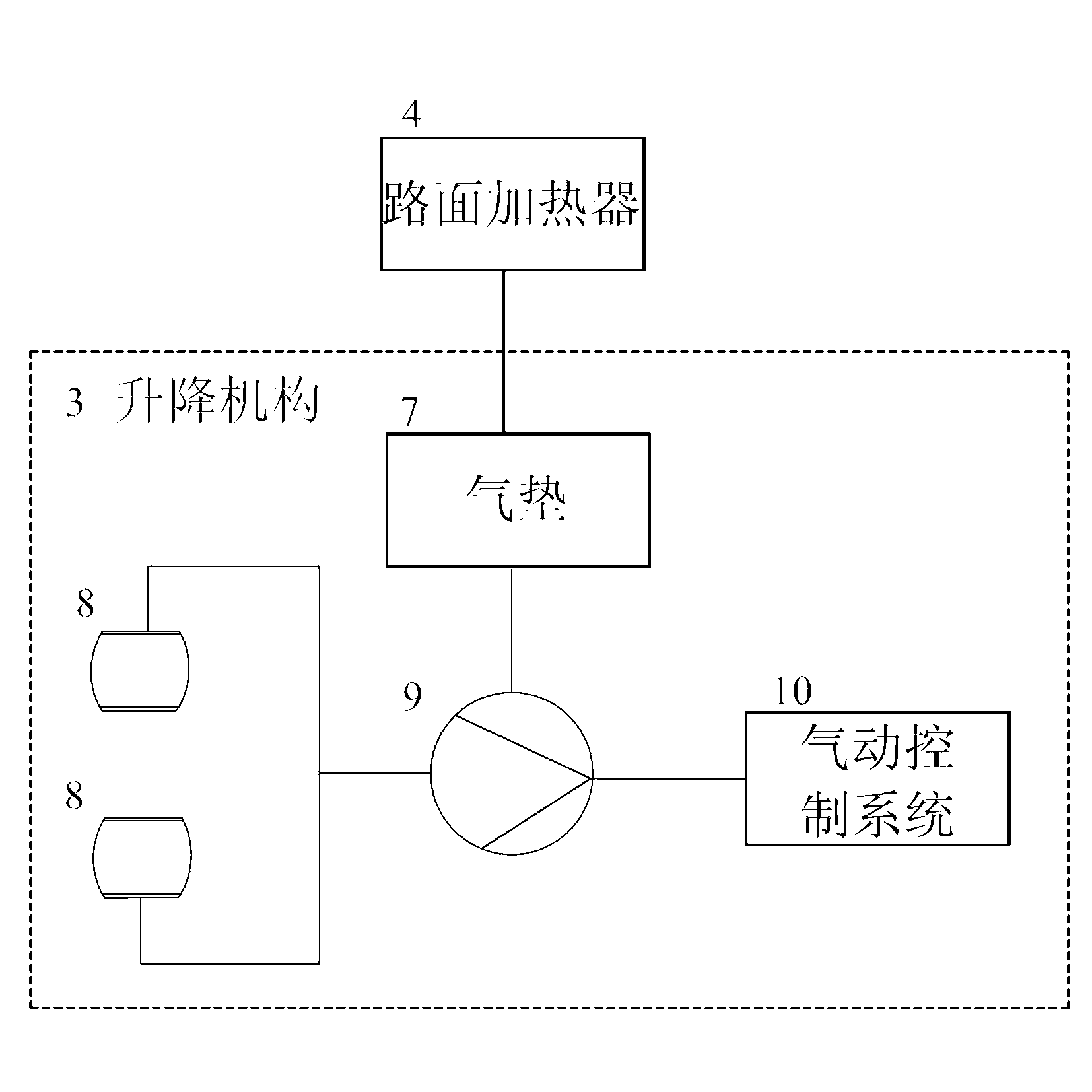

[0028] Please refer to Figure 1 to Figure 3 Shown, it has shown the specific structure of preferred embodiment of the present invention, comprises main controller 1, is used to send the height sensor 2 of road surface height signal to main controller 1, implements main controller 1 output command The lifting mechanism 3, the road heater 4 driven by the lifting mechanism 3 to lift or move down, the heating switch circuit 5 controlled by the main controller 1 to open or close, the heating switch circuit 5 is connected to the road heater 4, when the road surface When the height between the heater 4 and the asphalt pavement is lower than the set value, the heating switch circuit 5 is disconnected, and the heating operation is stopped; in addition, the main controller 1 is also connected with a display for displaying and inputting control commands for the operator With man-machine interface6.

[0029] Wherein, the road surface heater 4 is a microwave heater, which is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com