Structure for inhibiting water flow cavitation of outlet structure

A technology for releasing water structures and water flow. It is applied in construction, water conservancy engineering, marine engineering and other directions, and can solve problems such as failure to prevent the formation of cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

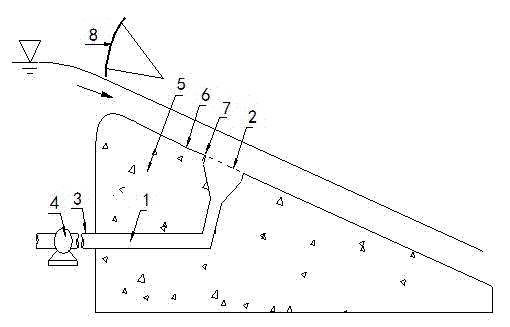

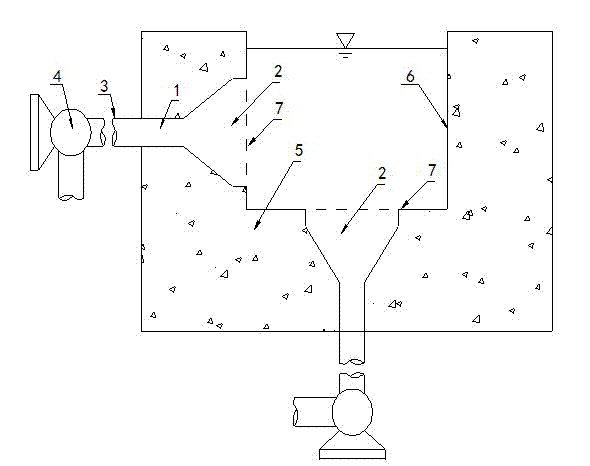

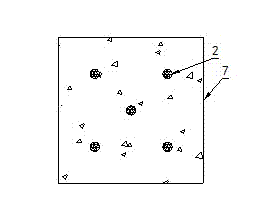

[0017] see Figure 1 to Figure 3 The structure for suppressing cavitation of water flow in a drainage structure includes a communication pipe 1 embedded in the drainage structure 5; the inlet end 3 of the communication pipe 1 is externally connected to a pressurizing device 4; the connection pipe 1 The outlet end 2 communicates with the flow wall 6 of the drainage structure 5, and the outlet end 2 of the connecting pipe 1 is a multi-orifice or a single orifice of a shower head type.

[0018] The discharge structure 5 is provided with a discharge gate 8 , and the pressurization device 4 is linked with the opening and closing system of the discharge gate 8 .

[0019] The pressurizing equipment 4 is an air compressor, and the displacement of the air compressor is 6m 3 / min, working pressure 0.8MPa.

[0020] The connecting pipe 1 is a steel pipe with a diameter of 200 mm.

[0021] The area of the water flow low pressure zone 7 is 10m 2 , open 5 orifices with a diameter of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com