Oil drainage method of split type fuel pump

A fuel pump, split technology, applied in the fuel valve of turbine/propulsion device, turbine/propulsion fuel delivery system, engine components, etc., can solve the problem of difficult fuel collection, increased maintenance workload and difficulty, easily polluted parts and environment and other problems, to achieve the effect of saving cleaning, easy modification and promotion, and good oil drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

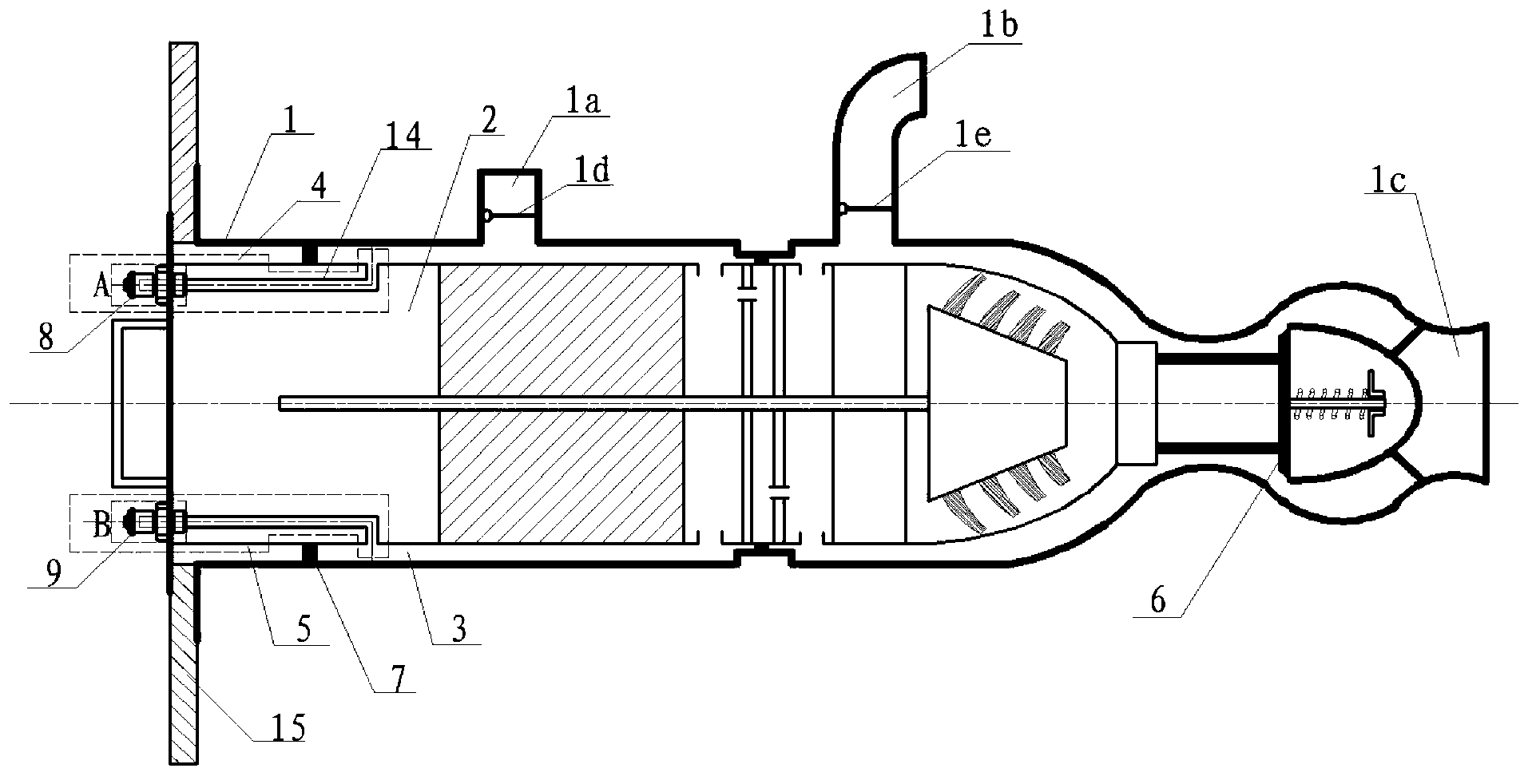

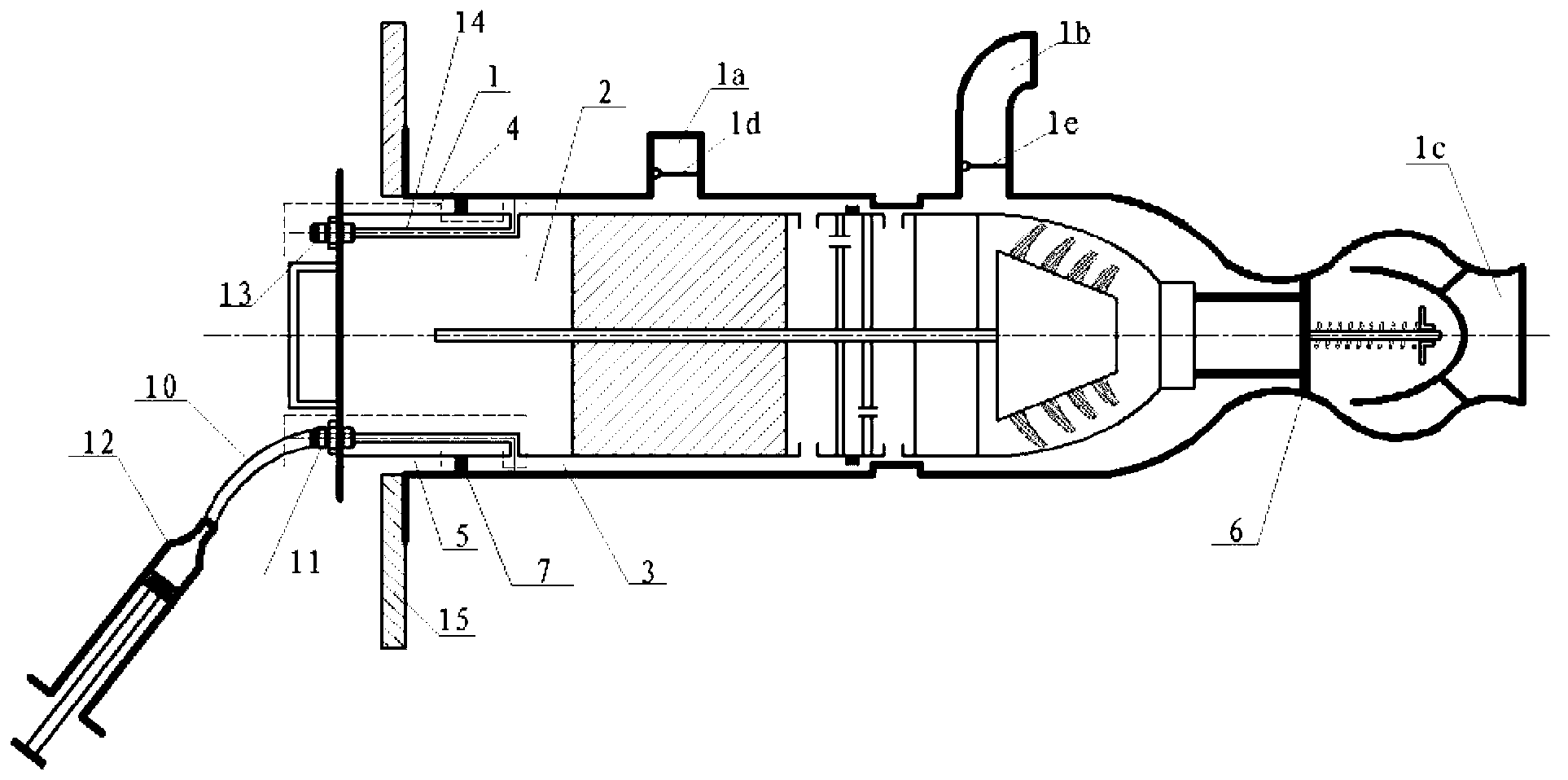

[0022] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 4 .

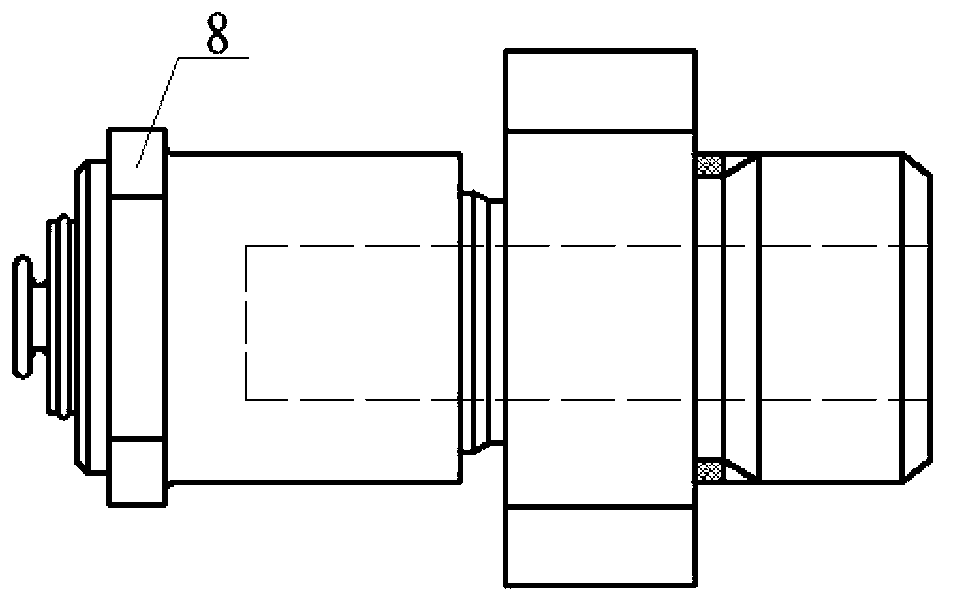

[0023] A split type fuel pump oil discharge method, when the split type fuel pump is installed (such as figure 1 As shown), the self-sealing valve 6 on the pump body 1 is in the open state, the ventilation plug cap 8 blocks the ventilation joint 13, the oil discharge plug cap 9 blocks the oil discharge joint 11, and the pump outlet one-way valve 1e in the pump outlet 1b It is in a closed state under the action of a spring, and the exhaust one-way valve 1d in the exhaust port 1a is in a closed state under the action of a spring.

[0024] When the split fuel pump is in the oil discharge state (such as figure 2 As shown), pull out the pump core 2 to the required position, at this time the self-sealing valve 6 on the pump body 1 is in a closed state, and the sealing structure 7 on the pump core 2 is in a sealed state in the pump b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com