Support integrated with installation seat of fuel pump of gasoline engine

A gasoline engine and mounting seat technology, which is applied to engine components, machines/engines, charging systems, etc., can solve the problems of no space for arranging high-pressure fuel pump supports and lowering pumping efficiency, and achieves solutions to layout problems and low costs. , the effect of good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limits.

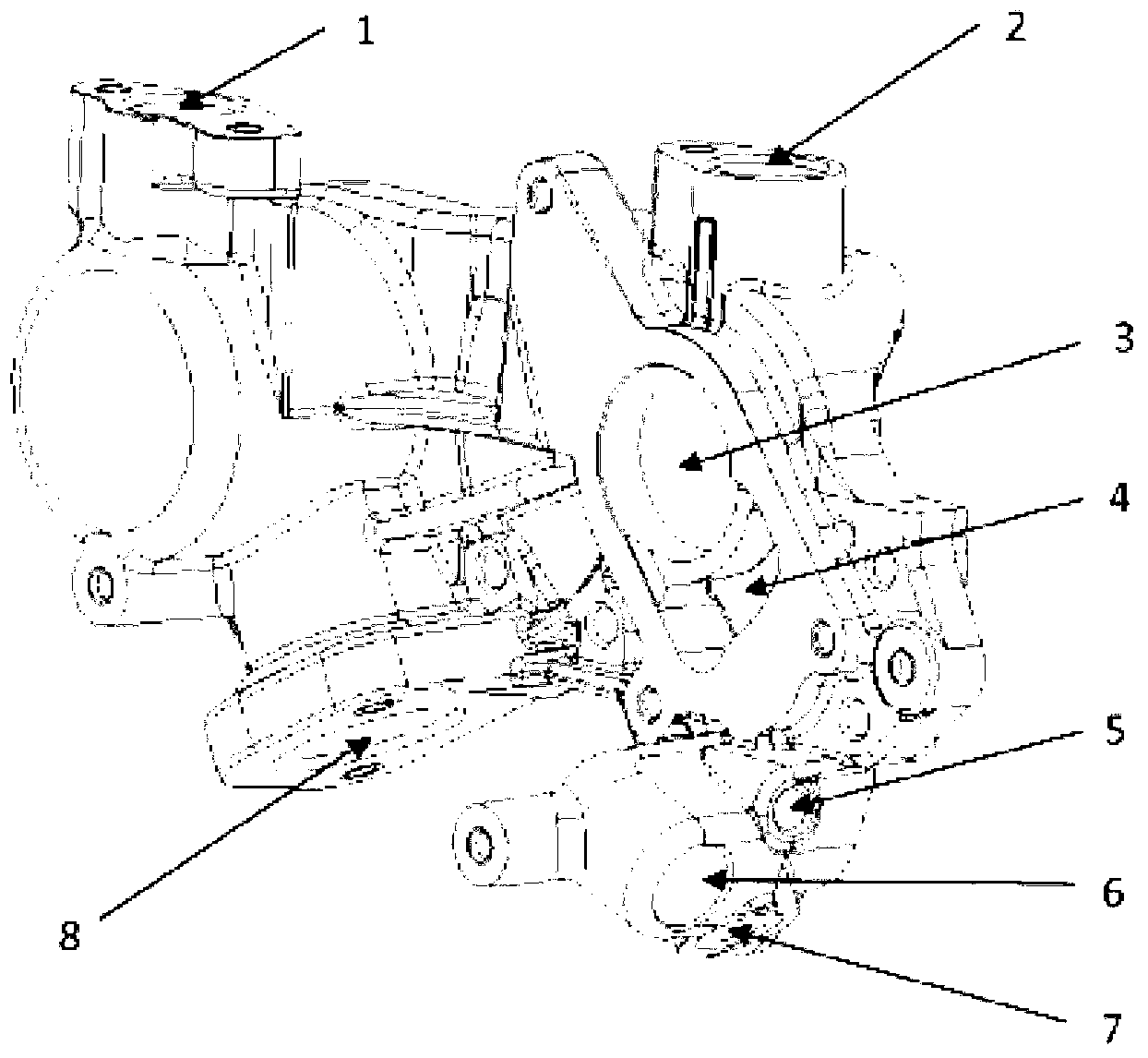

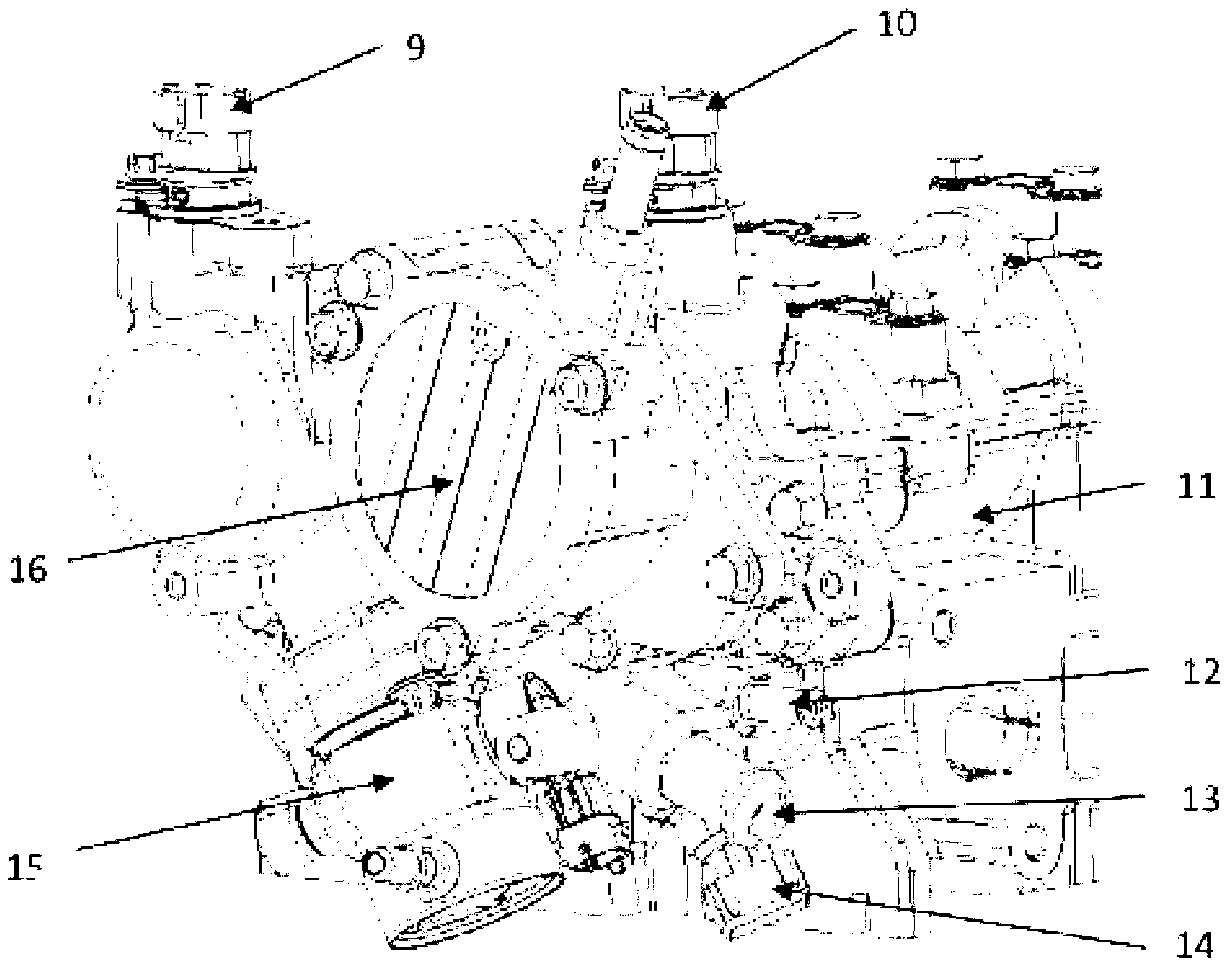

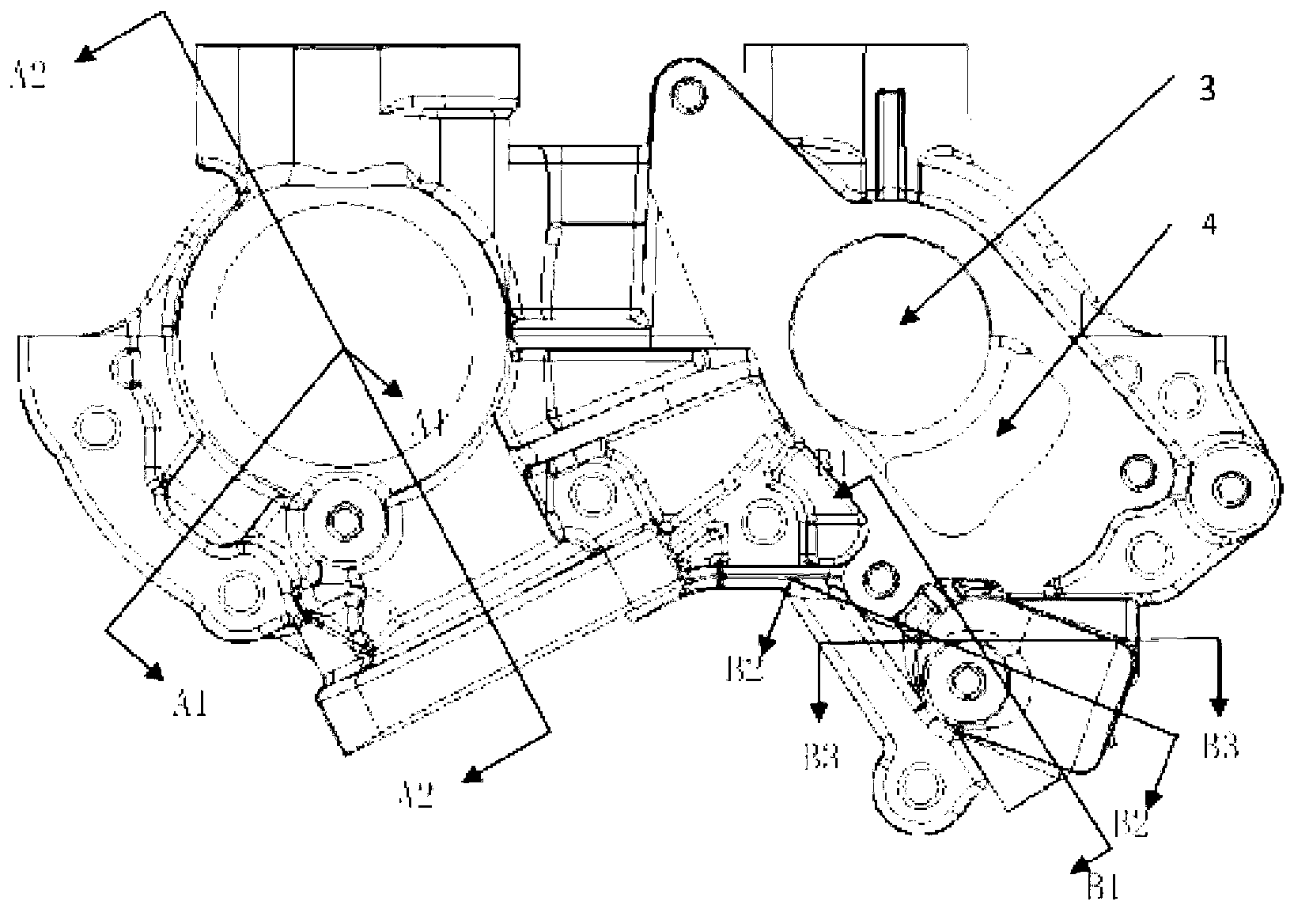

[0029] The invention provides a support structure integrated with a high-pressure fuel pump mounting seat, the support is installed at the rear end of the engine cylinder head, and the support also integrates a vacuum pump mounting seat, a high-pressure fuel pump mounting The installation structure of the water steel pipe installation seat, the throttle valve preheating water inlet steel pipe installation seat, the water temperature sensor installation seat and the camshaft phase sensor installation seat, etc.

[0030] figure 1 It is the overall structure diagram of the support integrated with the fuel pump mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com