Four acting harmonic gear pump

A gear pump and harmonic technology, applied in the field of hydraulic pumps, can solve the problem of oil suction and discharge only once, and achieve the effects of reduced gap leakage, small vibration, and improved stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

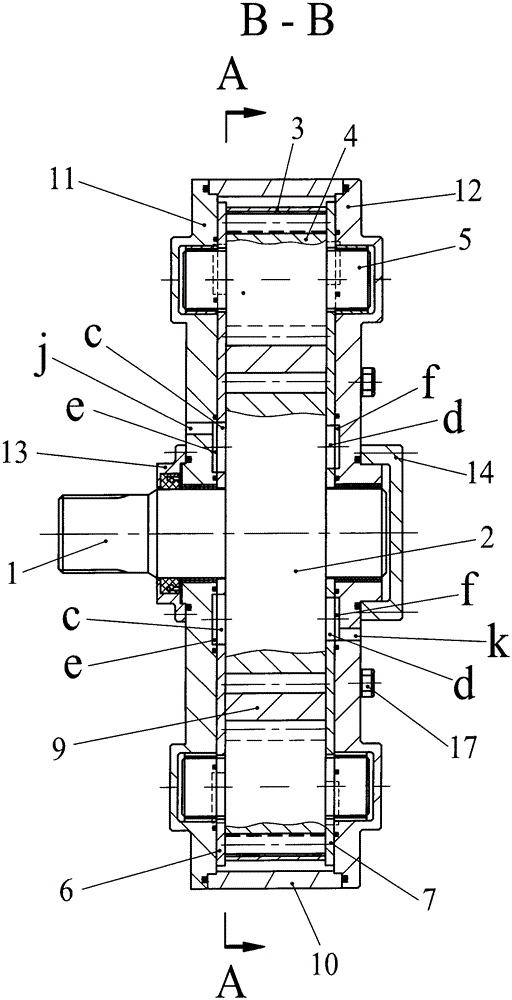

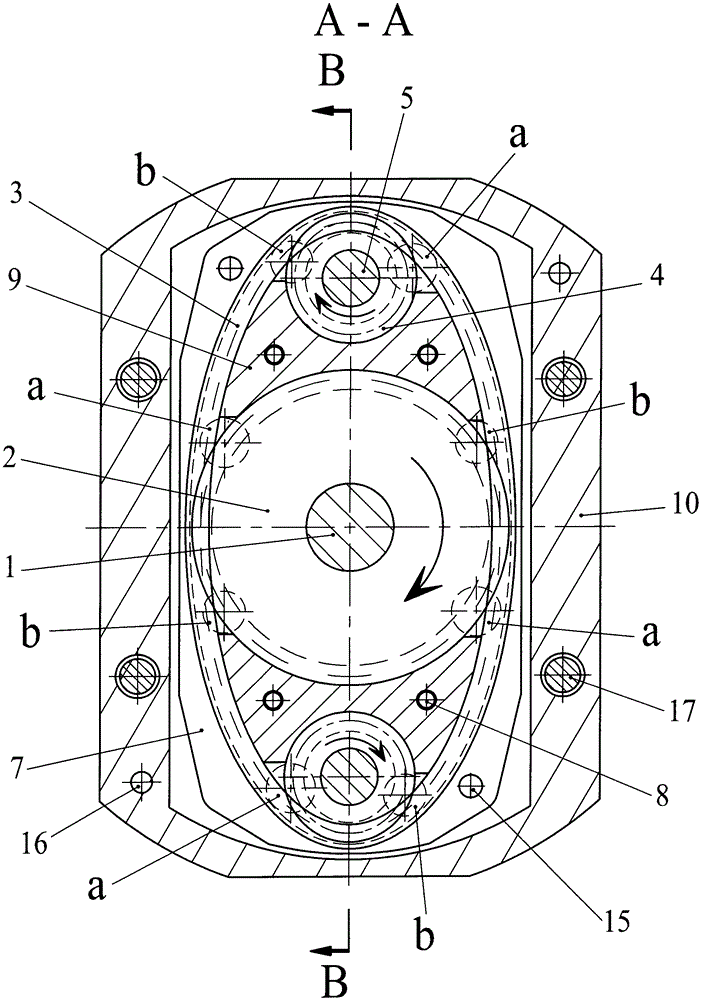

[0019] figure 1 and figure 2 It is an embodiment disclosed by the present invention. The four-action harmonic gear pump of the present invention consists of a driving shaft 1, a driving rigid wheel 2, a flexible wheel 3, a driven rigid wheel 4, a driven shaft 5, a left side plate 6, a right side plate 7, a sealing block 9, a front Bearing block 11, rear bearing block 12, pump body 10 etc. are formed. The main points of its structure are: the driving rigid wheel 2 and the driven rigid wheel 4 are both rigid gears, and the axis lines of the two are parallel; The center line of the centerline coincides and meshes with the driving rigid wheel 2 and the driven rigid wheel 4 respectively. The driving rigid wheel 2 has the same tooth width as the flexible wheel 3 and the driven rigid wheel 4; the sealing block 9 and the left plate 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com