Chain transmission

A technology of chain transmission and chain, which is applied in the direction of transmission device, transmission chain, belt/chain/gear, etc., and can solve the problem of not being able to reduce the assembly burden of roller chain 510

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

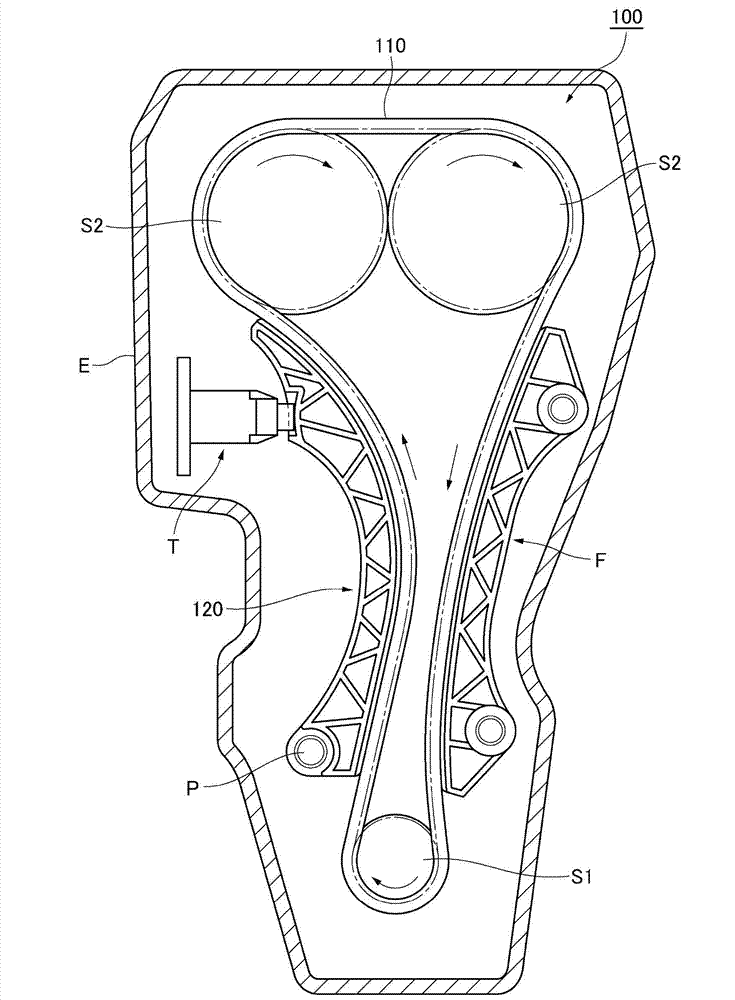

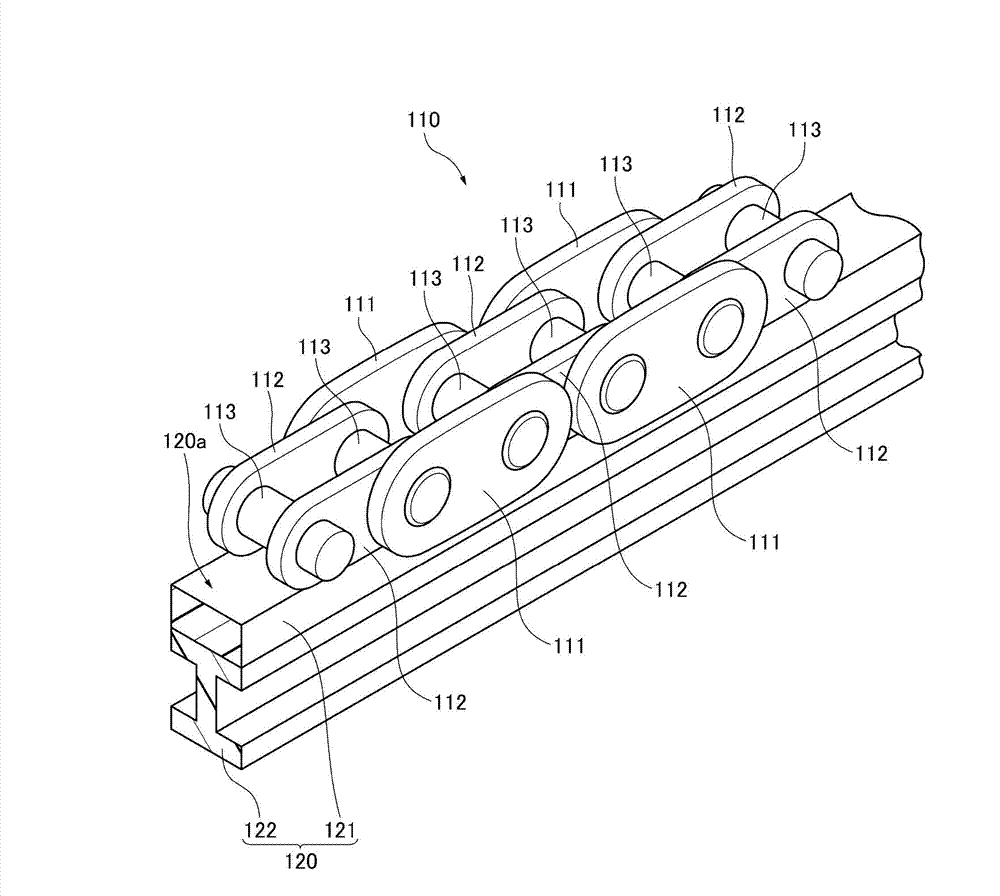

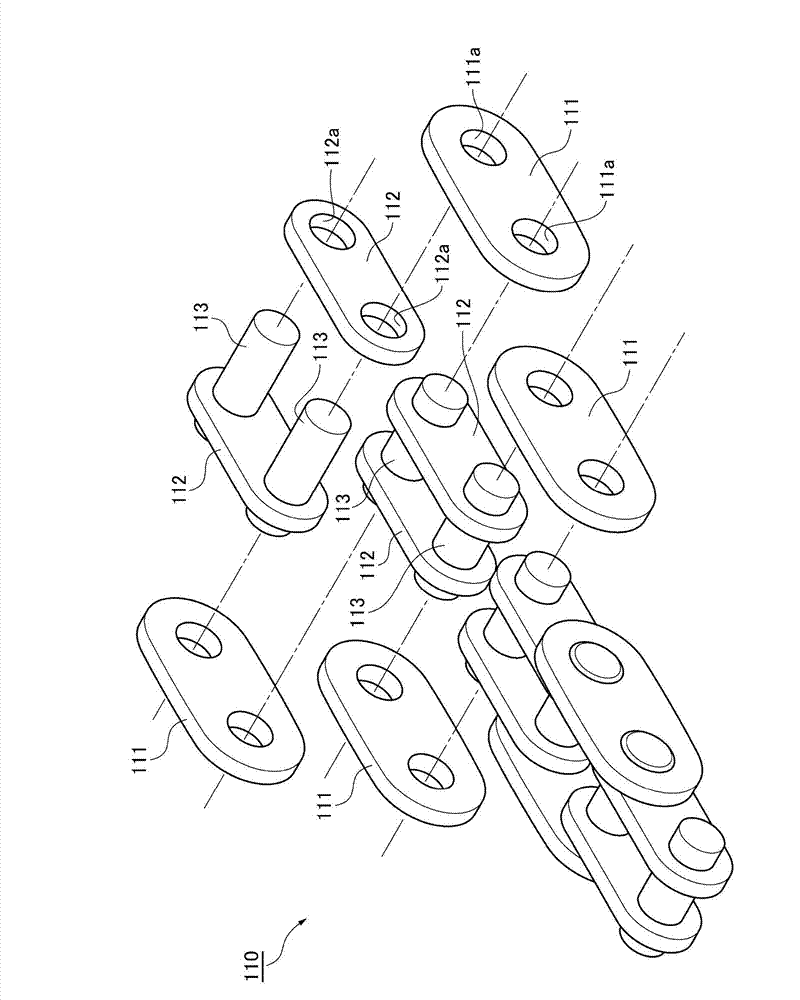

[0069] The chain transmission device of the present invention has a pair of left and right outer chain plates which are alternately combined in the chain length direction and freely connected by connecting pins and arranged separately in the chain width direction, and between the left and right outer chain plates along the chain width. A transmission chain composed of a pair of left and right inner link plates arranged separately in direction, and a chain guide for slidingly connecting and moving the transmission chain along the chain length direction. The structure of the transmission chain is: press-fit connecting pins into the pin press-in holes provided on the pair of left and right inner chain plates, and loosely insert them into the pin loose sleeve holes provided on the pair of left and right outer chain plates Connecting pins, which can permanently suppress the elongation of the chain due to the bending of the connecting pins, at the same time, reduce the assembly load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com