Petroleum pipeline with sealing structure comprising ring grooves

A sealing structure and oil pipeline technology, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc., can solve the problems of oil pipeline interface sealing and other problems, achieve the effect of wide market demand and reduce design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

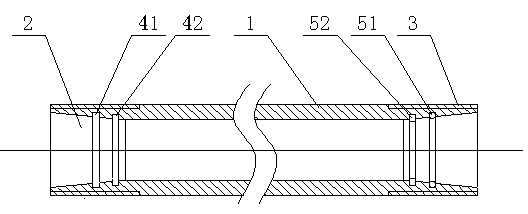

[0012] Such as figure 1 As shown, an oil pipeline with a ring groove sealing structure according to the embodiment of the present invention includes a main body 1, and the two ends of the main body 1 are respectively provided with inner tapered surfaces 2 with the same taper and equal length. The surface of 2 is a smooth surface, and the angle of the cone angle of the inner cone surface 2 relative to the axis of the body is 3-5 degrees, and each of the inner cone surfaces 2 is provided with a first annular groove 41 and a second groove. Two annular grooves 42, the diameter of the first annular groove 41 is greater than the diameter of the second annular groove 42; in the first annular groove 41, a first sealing ring 51 is embedded and installed, in the first annular groove 41 A second sealing ring 52 is embedded in the second annular groove 42 .

[0013] The cross section of the first sealing ring 51 is circular.

[0014] The cross-section of the second sealing ring 52 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com