Wheel type crane and centre revolving joint thereof

A center rotary joint, rotary body technology, applied in the direction of connection, rotary current collector, current collector, etc., can solve the problem of difficult processing of rotary body, to ensure work reliability and safety, improve sealing effect, prevent leakage flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

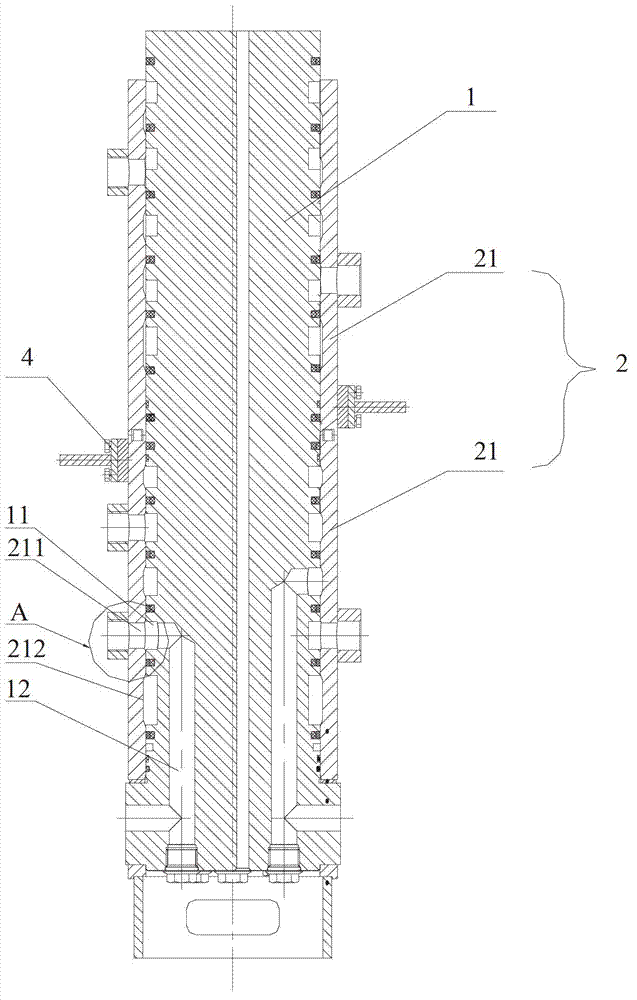

[0034] The core of the present invention is to provide a central rotary joint. By setting the rotary body of the central rotary joint separately, and then splicing them into a rotary body that meets the size requirements of the long central rotary joint through segmental processing of ordinary machine tools, the weight of the rotary body is reduced. Processing difficulty, thereby reducing the overall manufacturing cost of the central rotary joint and shortening its manufacturing cost. On this basis, the present invention also provides a wheeled crane including the above-mentioned central swivel joint.

[0035] Without loss of generality, the first specific embodiment of the central swivel joint provided by the present invention will now be described with reference to the accompanying drawings.

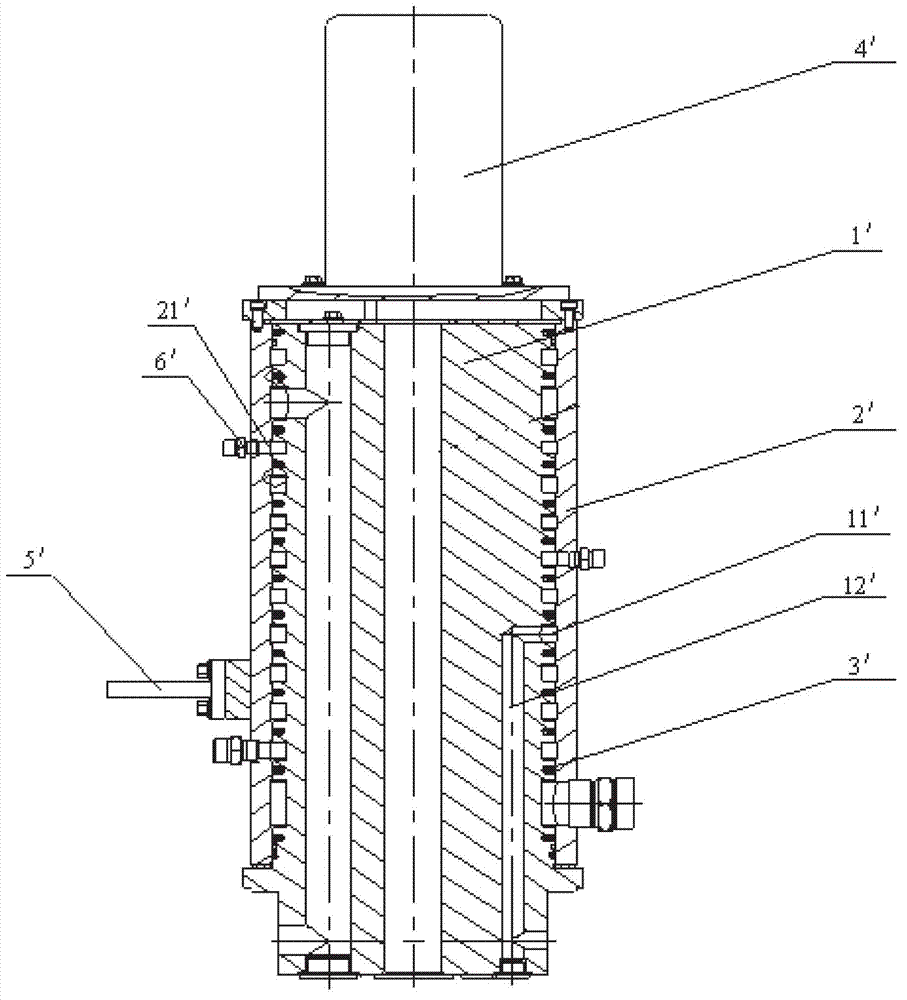

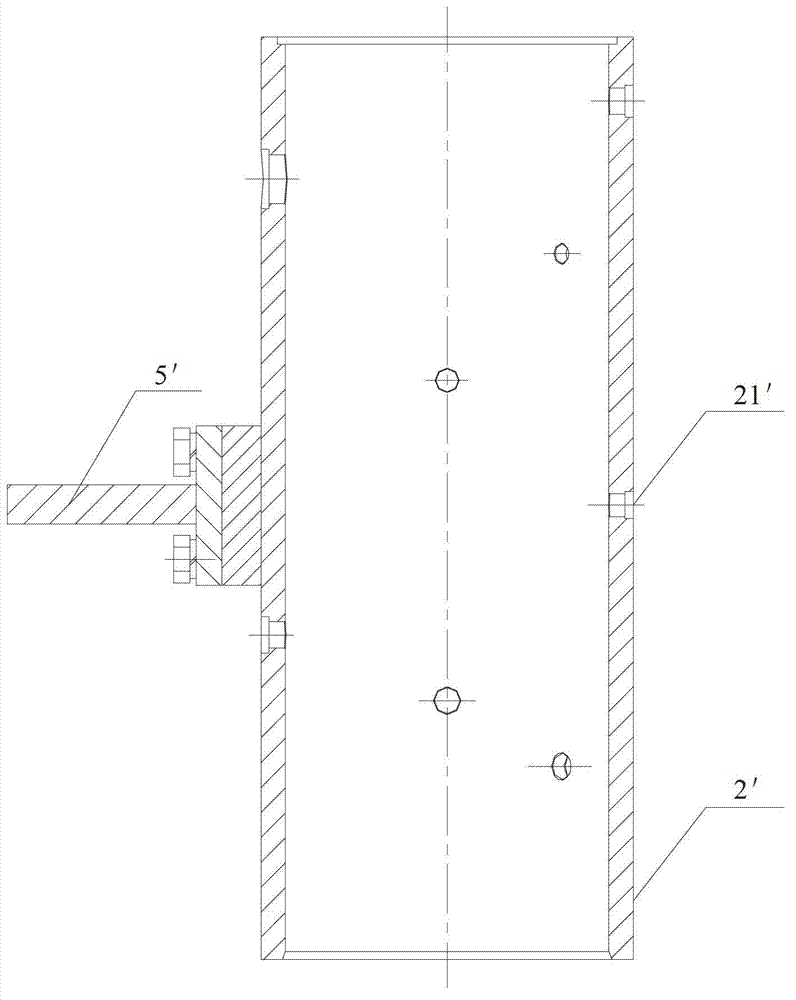

[0036] See image 3 , Figure 4 and Figure 5 ,in, image 3 A schematic structural view of the first specific embodiment of the central rotary joint provided by the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com