Dissolving method of high purity titanium dioxide

A titanium dioxide, high-purity technology, applied in the field of high-purity titanium dioxide dissolution, can solve the problems of small amount of sample dissolution, distortion of analysis data, long time consumption, etc., reduce the influence of interference signals, scientific and simple operation process, and improve the efficiency of analysis and testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] 1) Grind high-purity titanium dioxide to a particle size > 300 mesh, put it in an oven at 110°C for 2 hours, and then cool to room temperature;

[0025] 2) Put the polytetrafluoroethylene standard reaction tanks (removing the lid on the reaction tank) that are numbered 1#, 2#, 3# respectively on the balance and weigh the high-purity titanium dioxide 1.0000g that step 1) obtains respectively, and Place them evenly in the standard polytetrafluoroethylene reaction tank;

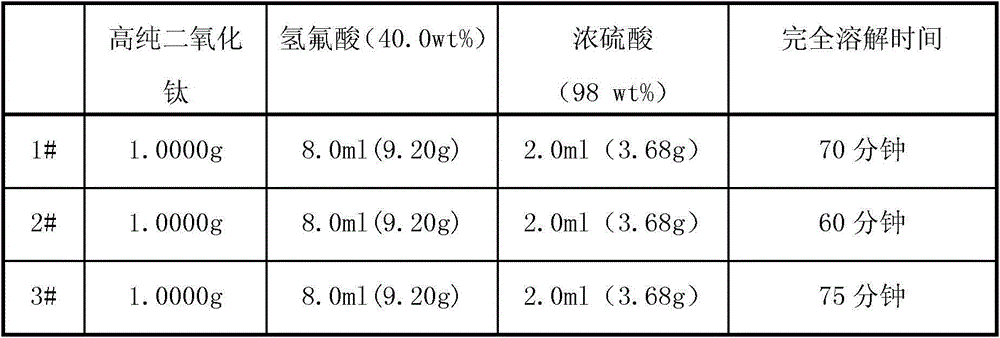

[0026] 3) Add 8.0ml of 40.0wt% hydrofluoric acid (9.20g by weight) and 5 drops of 30.0wt% hydrogen peroxide into the polytetrafluoroethylene standard reaction tank numbered 1# with a pipette gun (conversion into weight is 0.36g); Adding 8.0ml purity is 40.0wt% hydrofluoric acid (conversion into weight is 9.20g) and 5 drops Purity is 30.0wt% hydrogen peroxide (converted into weight and is 0.36g); Add 8.0ml of purity into 40.0wt% hydrofluoric acid (converted into weight) in the polytetrafluoroethylene stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com