Method for dissolving high purity zirconia

A zirconia, high-purity technology, which is applied in the field of high-purity zirconia dissolution, can solve the problems of poor accuracy and precision of measurement results, less sample melting amount, and great harm to human body and environment, so as to reduce the influence of interference signals , lower the detection limit of the analysis and improve the sensitivity of the analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

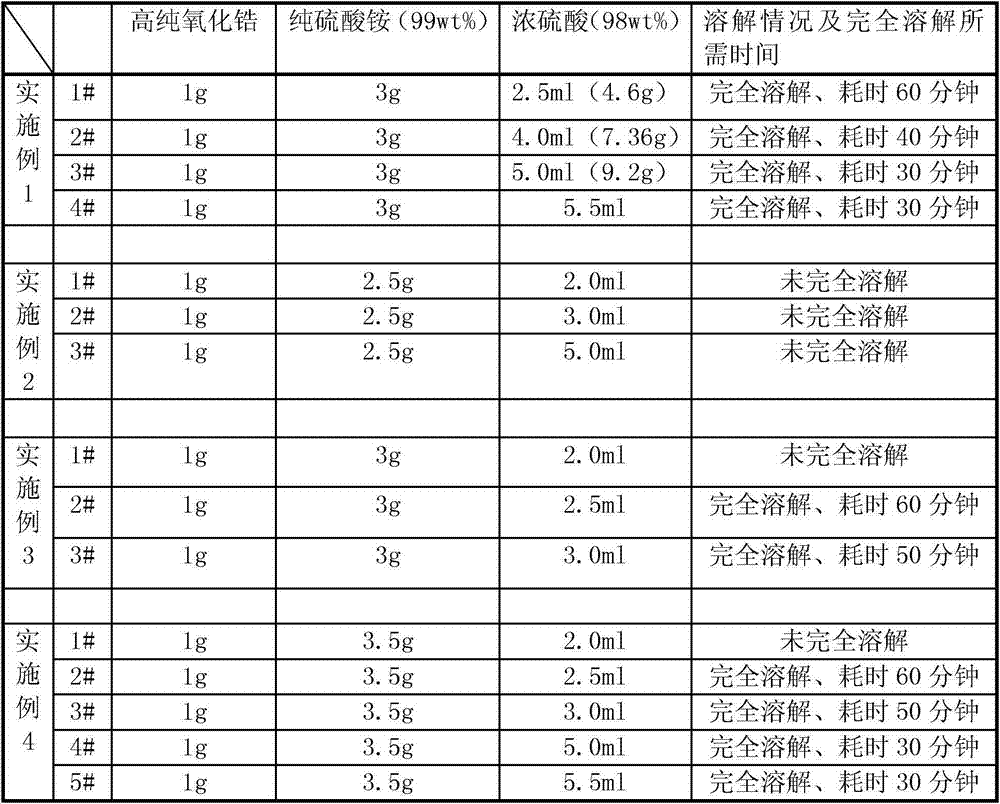

Examples

Embodiment

[0024] 1) Grind high-purity (purity > 99.95%) zirconia with an agate mortar to a particle size ≥ 320 mesh, place it in a porcelain crucible, put it in a resistance furnace and burn it at 900°C for 1 hour, then cool to room temperature;

[0025] 2) Place the beaker numbered 1# on the balance and weigh 3g of analytically pure ammonium sulfate with a particle size of ≥100 mesh and a purity of 99wt%, and place it evenly on the bottom of the beaker; then weigh the high-purity ammonium sulfate obtained in step 1). Zirconium 1g, place it evenly on the surface of analytically pure ammonium sulfate; place the beaker numbered 2# on the balance and weigh 3g of analytically pure ammonium sulfate with a particle size ≥ 100 mesh and a purity of 99wt%, and place it evenly in the beaker Bottom; then weigh the high-purity zirconia 1g that step 1) obtains, and place it evenly on the surface of analytically pure ammonium sulfate; place the beaker that is numbered 3# on the balance and weigh the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com