Fruit surface defect detection method based on visual saliency

A defect detection and remarkable technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as poor effect and large amount of calculation, and achieve the effect of increasing the depth of automation, eliminating interference, and promoting industrial development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

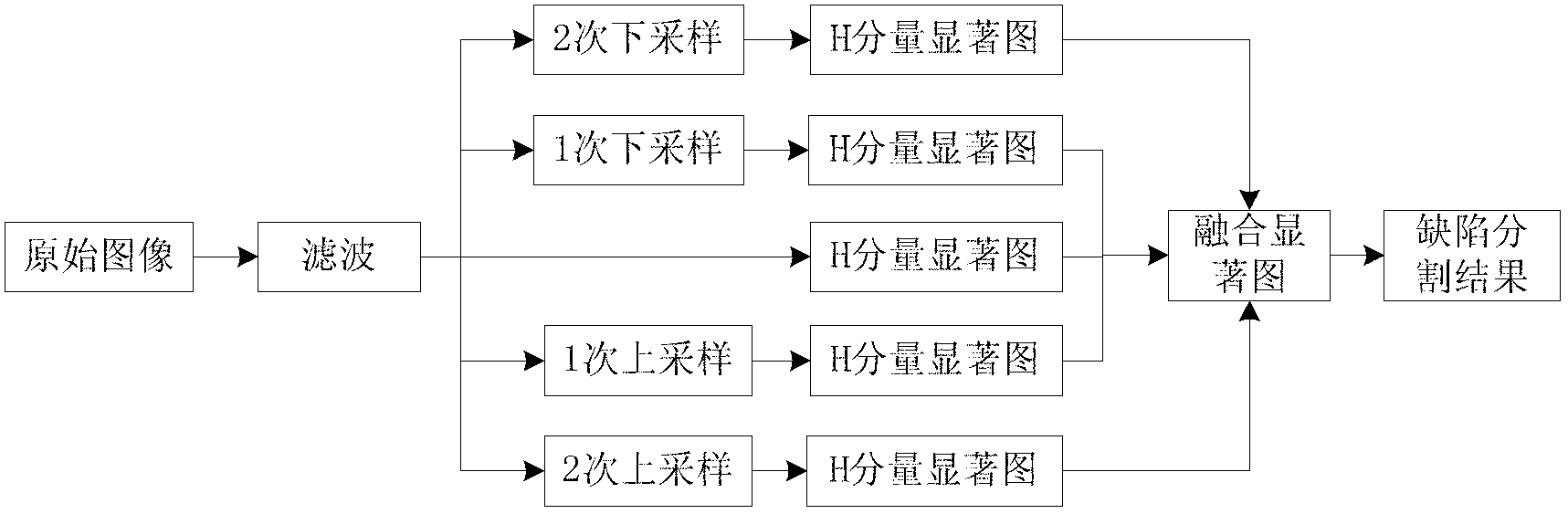

[0028] The present invention uses apples as the measured object, and the processing flow is as attached figure 1 As shown, the specific implementation steps are as follows:

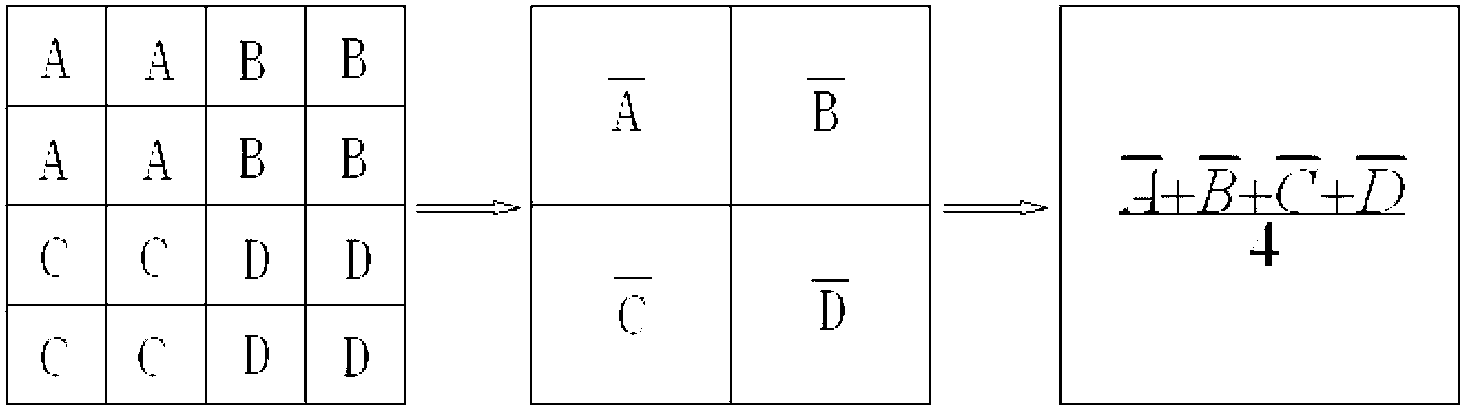

[0029] Step1, obtain the original image of tested apple by CCD camera, I 3 : M×N dimensions. Since 4 times downsampling is required, both M and N are multiples of 4, and images with a resolution of 320*240 are generally used.

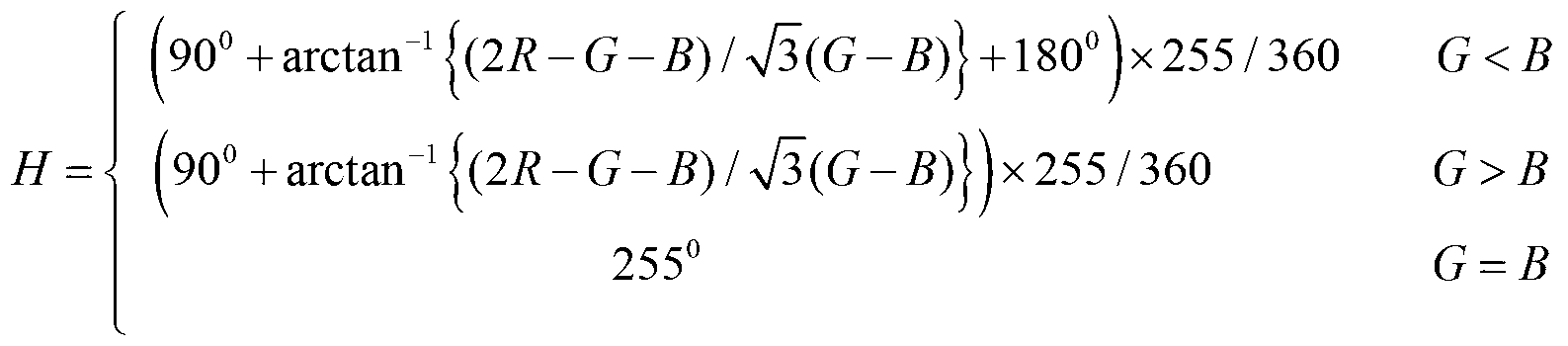

[0030] Step 2. The original image is filtered, and the size of the selected filtering window is 5×5 pixels. The specific method is to use the filter window to perform sliding scanning from the upper left corner of the original image to judge whether there are noise points. The basis for judging is whether there is a sudden change in the value in the window area. The weighted average of the value is used to replace the value of the noise point. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com