Method for Determining Radial Stress of Shock Absorber Annular Superimposed Valve Plate under Non-uniform Pressure

A technology of non-uniform distribution of pressure and radial stress, applied in the field of hydraulic shock absorbers, can solve the problems of not being able to provide analytical calculation formulas and calculation methods, and not being able to meet the requirements of shock absorber split design and strength check

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

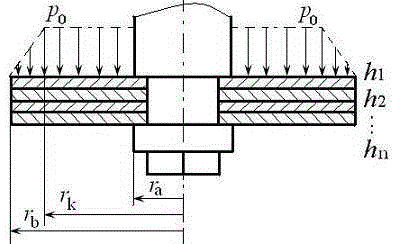

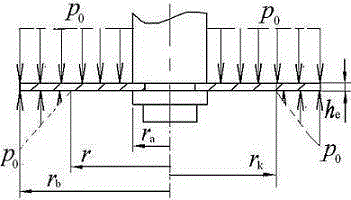

[0060] Example 1: The radius r of the inner circle of a circular superimposed valve plate of a certain shock absorber a =5.0mm, outer circle radius r b =8.5mm, valve port radius r k = 8.0mm, elastic modulus E = 200GPa, Poisson's ratio μ = 0.3, three different thicknesses of annular superimposed valve plates and the corresponding number of plates, respectively h 1 = 0.1 mm, n 1 = 3; h 2 = 0.15mm, n 2 = 2; h 3 = 0.2mm, n 3 = 1, in the interval [r a , r k ] distributed uniform pressure p 0 =3.0MPa, in the interval [r k , r b ] Distribution of pressure p = p 0 [1-(r-r k ) / (r b -r k )] MPa. Determine the radial stress of the annular superimposed valve plate of the shock absorber under non-uniform pressure.

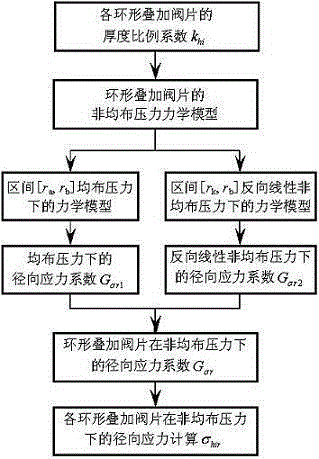

[0061] The method for determining the radial stress of the annular superimposed valve plate of the shock absorber provided by the example of the present invention under non-uniform pressure, its process is as follows image 3 As shown, the specific steps are as...

Embodiment 2

[0097] Embodiment 2: The inner circle radius, outer circle radius and material characteristics of the valve plate of a shock absorber valve plate superimposed are exactly the same as those in Example 1. The three different thicknesses of the superimposed valve plate and the corresponding number of plates are respectively h 1 = 0.1 mm, n 1 = 1; h 2 = 0.15mm, n 2 = 1; h 3 = 0.2mm, n 3 =1, valve port radius r k =7.0mm, in the interval [r a , r k ]Distributed uniform pressure p=p 0 =3.0MPa, in the interval [r k , r b ] Distribution of pressure p = p 0 [1-(r-r k ) / (r b -r k )] MPa. Determine the radial stress of the annular superimposed valve plate of the shock absorber under non-uniform pressure.

[0098] The calculation steps of Embodiment 1 are adopted, namely:

[0099] (1) Determine the equivalent thickness h of the annular stacked valve plate e :

[0100] According to the three different thicknesses of annular superimposed valve slices and the corresponding nu...

Embodiment 3

[0130] Embodiment 3: The material characteristic parameters, inner circle radius and valve position radius of a shock absorber annular superimposed valve plate are the same as those in Embodiment 1, and the outer circle radius r b =8.75mm, the two different thicknesses of stacked valve plates and the corresponding number of plates are h 1 = 0.15mm, n 1 = 1; h 2 = 0.2mm, n 2 = 3, in the interval [r a , r k ] distributed uniform pressure p 0 =3.0MPa, in the interval [r k , r b ] Distribution of pressure p = p 0 [1-(r-r k ) / (r b -r k )] MPa. Determine the radial stress of the annular superimposed valve plate of the shock absorber under non-uniform pressure.

[0131] The calculation steps of Embodiment 1 are adopted, namely:

[0132] (1) Determine the equivalent thickness h of the annular stacked valve plate e :

[0133] According to the two different thicknesses of stacked valve plates and the corresponding number h 1 = 0.15mm, n 1 = 1; h 2 = 0.20mm, n 2 = 3, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com