Device for preventing upwarping of lithium battery coating pole piece

A lithium battery and pole piece technology, which is applied in the field of devices for preventing pole piece upturning, can solve problems such as edge upturning, floating roller cracks, broken belts, etc., so as to achieve the effects of preventing upturning, reducing failure rate and improving pole piece quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

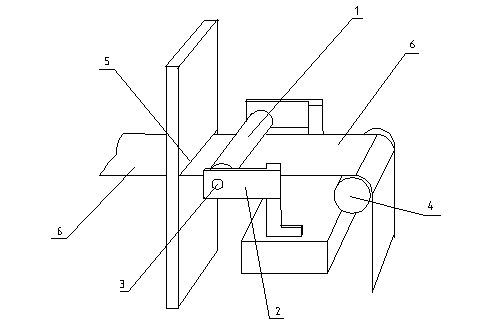

[0011] Such as figure 1 As shown, a device for preventing the upturning of the lithium battery coated pole piece includes: the oven outlet 5 of the coating machine, and the floating roller 4 arranged in front of the oven outlet 5, and the oven outlet 5 of the coating machine is located at the pole piece 6 Above, on the two coater side walls 2, a roller 1 that is in contact with the pole piece 6 is installed.

[0012] The two side walls 2 of the coating machine are provided with through holes 3, and the small shafts at both ends of the passing roller 1 are in clearance fit with the through holes 3, and the passing roller 1 and the pole pieces in the conveying process 6 contacts, the passing roller 1 keeps rotating, which can realize the re-flattening of the curled pole piece 6, and when passing through the floating roller 4, the pole piece 6 will not be broken or torn due to internal stress, which will cause broken belts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com